Score type splitting structure of splitting machine

A slitting machine and slitting technology, applied in the field of machinery, can solve the problems of easy sticking of the cutter, low slitting precision, and the slitting structure cannot meet the slitting of thick tapes, so as to prevent the sticking knife from collapsing and slitting. convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

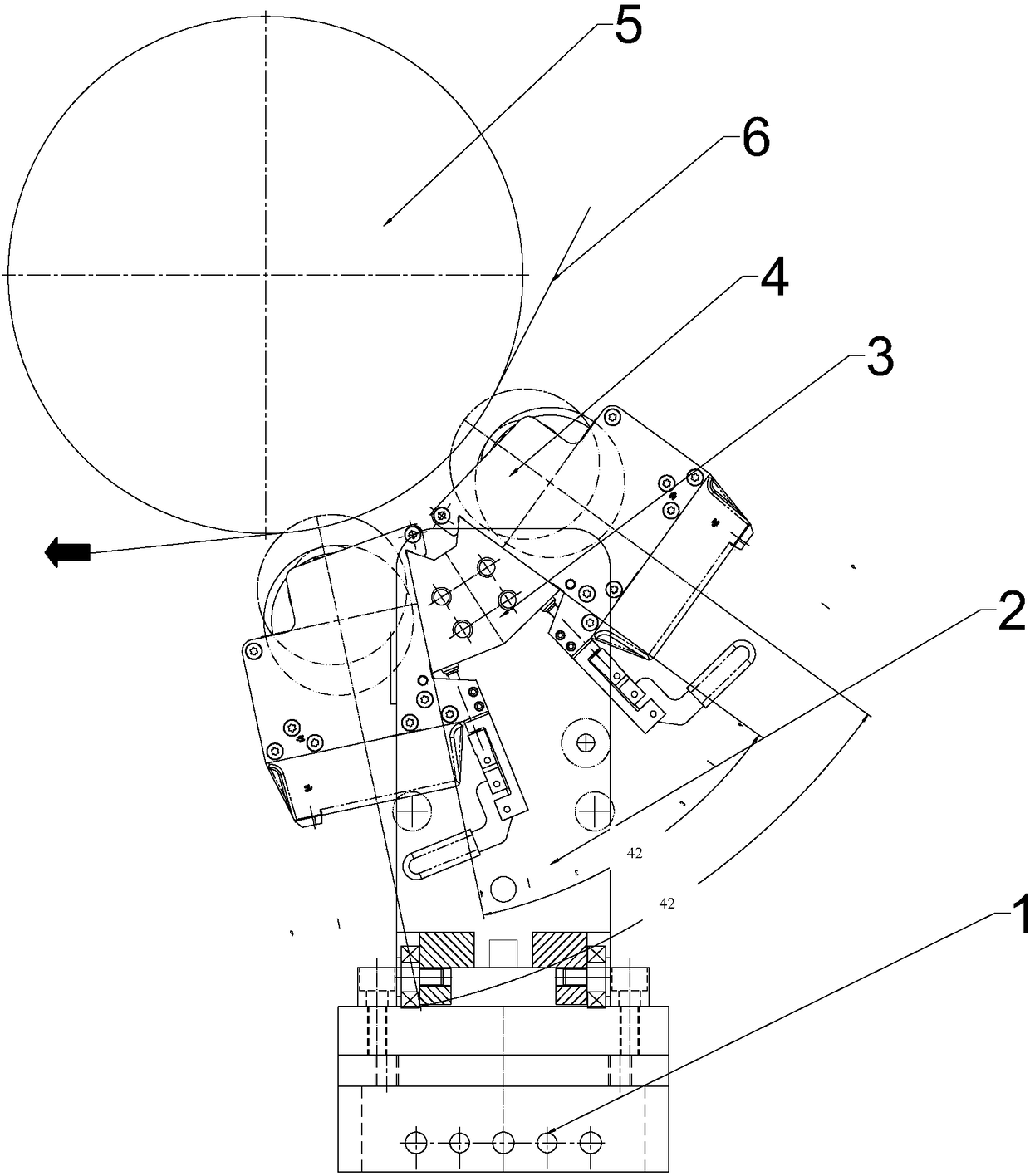

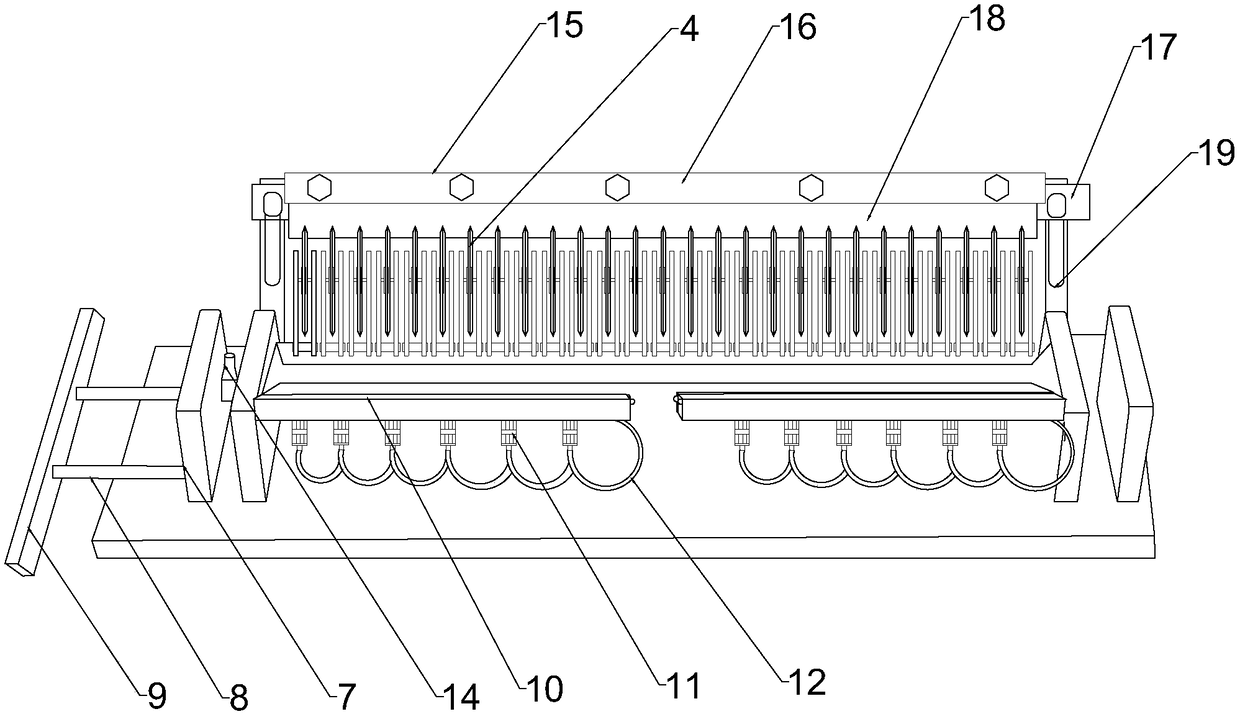

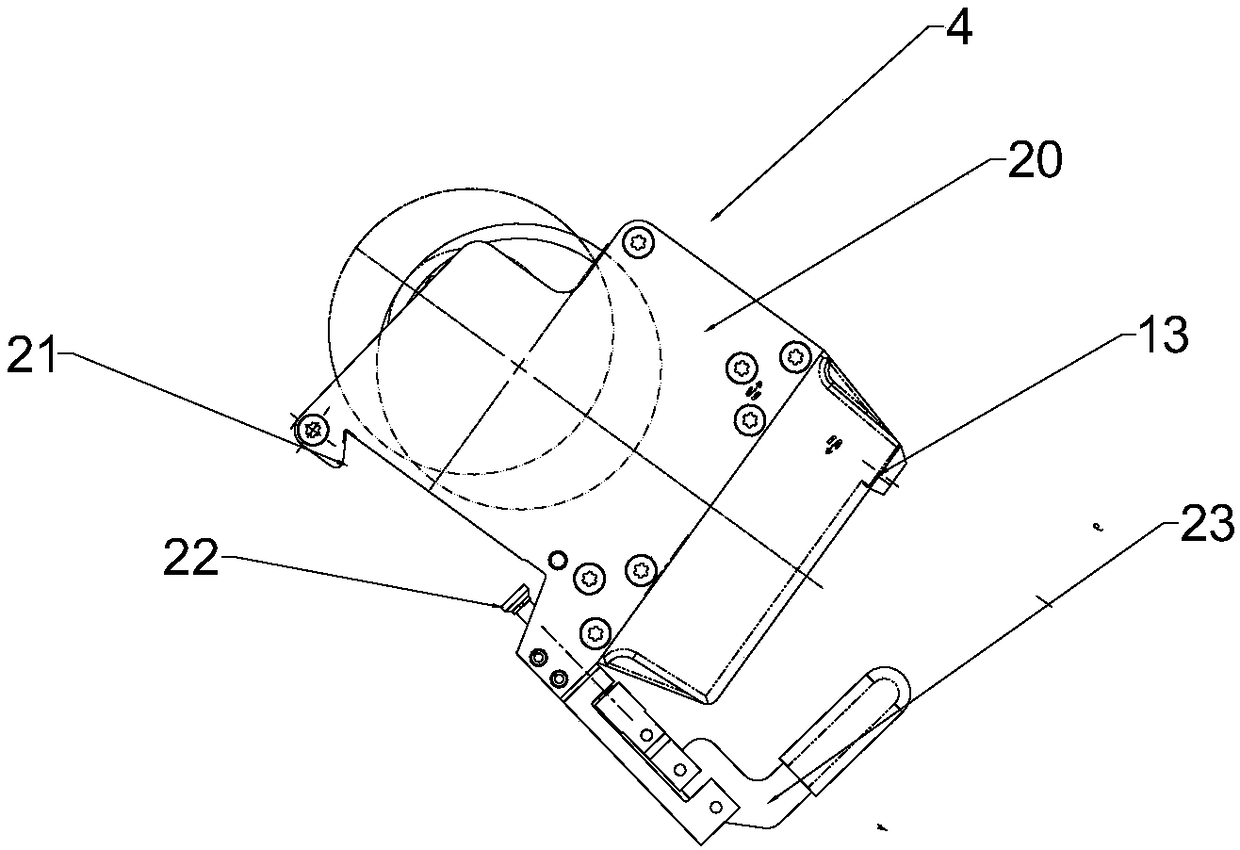

[0040] Such as Figure 1-4 In the shown embodiment, a kind of slitting machine pressure-cutting type slitting structure comprises tool support 1, and described tool support 1 is provided with two knife rest wall boards 2 that are arranged in parallel, and described knife support wall A double-sided dovetail groove block 3 is fixedly connected between the plates 2, and the two sides are designed at an angle of 42°. The double-sided dovetail groove block 3 is fixedly connected with the pneumatic pressure cutter 4, and the pneumatic pressure cutter 4 During operation, the coil 6 located on the surface of the bed knife roll 5 is cut against the bed knife roll 5 coated with the tungsten carbide layer 24 on the surface.

[0041]The pressure-cutting slitting process is adopted, which can effectively slit the thicker coils. At the same time, the pneum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com