Preparation method of ready-to-eat mushroom stem chips

A technology of mushroom stalk and time, applied in the fields of food drying, food science, food freezing, etc., can solve the problems of poor swallowability of freeze-dried mushroom stalk crispy strips, unfavorable human health, high oil content, and improve palatability and attractive color. , Crispy taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

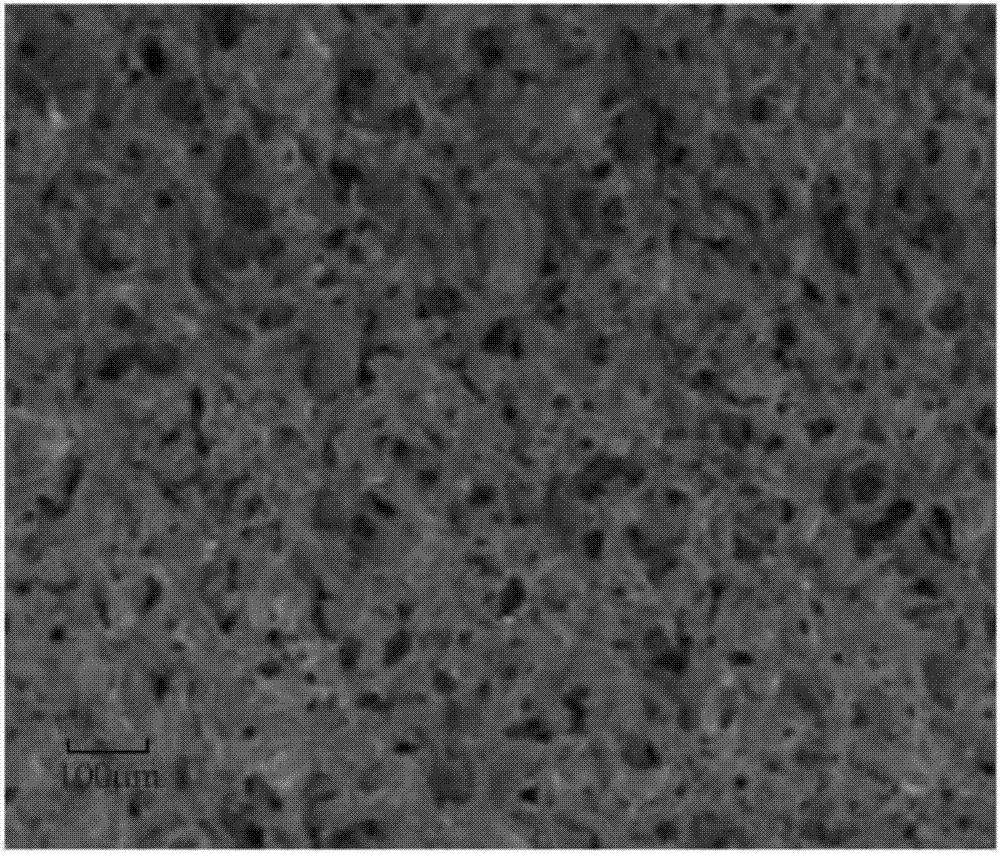

Image

Examples

Embodiment 1

[0025] Embodiment 1: the preparation of ready-to-eat mushroom shank crispy strips

[0026] Use fresh mushroom stalks as raw materials, cut off the base of the mushroom stalks and wash the surface debris, soil, compost, etc. with clean water, cut the mushroom stalks and grade them according to thickness. Put 100g of cleaned fresh mushroom stalks into 0.5L mixed enzyme solution composed of cellulase and protease (cellulase 1000U / mL, protease 2000U / mL), enzymolysis treatment for 3h; Blanch and pre-cook in boiling water for 30 minutes; remove the mushroom stalks, drain and cool, then soak in 0.8L of 20% maltodextrin solution containing marinade (also containing 1% sesame oil, 10% sugar, 0.8% soy sauce and 0.8% salt), 25KHz low-frequency ultrasonic assisted impregnation for 30 minutes; remove the soaked mushroom stems and drain them, and put them in a -40°C freezer for pre-freezing for 2 hours; put the pre-frozen mushroom stems in a vacuum Freeze dry in stages in a freeze dryer, v...

Embodiment 2

[0033] Embodiment 2: the finished product quality comparison prepared by different embodiments and comparative examples

[0034] (1) Determination of brittle bars and hardness: use TA-XT plus texture analyzer to measure, and use HDP / 3PB three-point bending probe. Fix the whole crispy strip of oyster mushroom on the operating table, press the probe down at a rate of 3.0mm / s, and the hardness is represented by the maximum peak value. The brittleness is represented by the distance moved from the upper support to the breaking point of the sample, and the smaller the distance, the greater the brittleness. Test speed: 3mm / s, drop distance: 5.0mm, return speed 10.0mm / s, return distance: 15mm. Each group of samples was repeatedly measured 10 times, and the average value was taken.

[0035] (2) Sensory evaluation: The sensory evaluation is evaluated from the four indicators of crispy strips, appearance, shape, taste, and mouthfeel. 20 professional sensory evaluators are randomly sele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com