A method for detecting the morphology of silver behenate crystals in a silver salt imaging material

A silver behenate and detection method technology, applied in the direction of analyzing materials, using radiation for material analysis, using radiation diffraction for material analysis, etc., can solve the problems of low success rate, endangering the health of operators, and high production costs, and achieve Reduce environmental hazards, reduce washing times, and improve dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

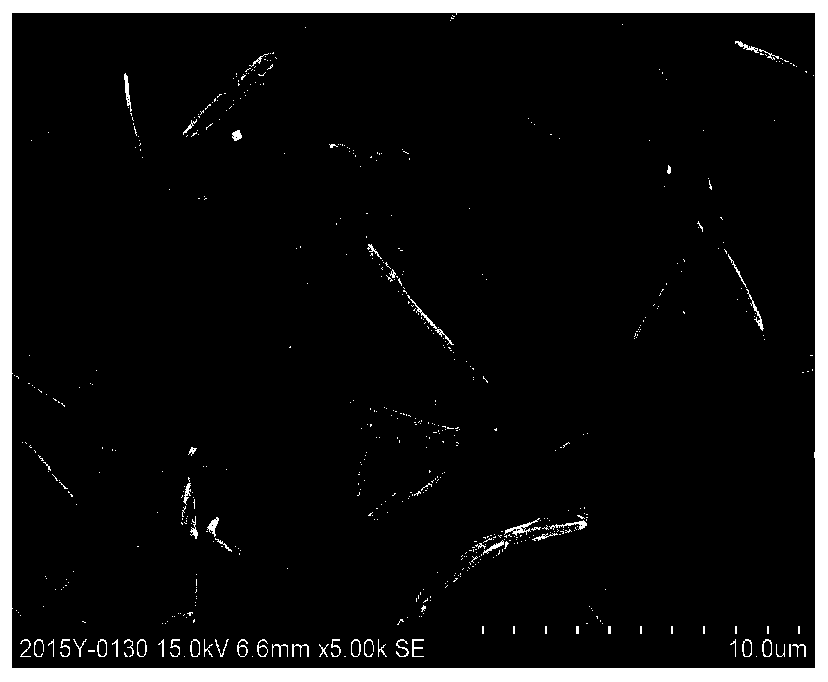

[0029] Embodiment 1: Silver behenate crystal morphology detection process

[0030] (1) Prepare a mixed solution of silver behenate crystals with a concentration of 50g / L. The solvent of the mixed solution is acetone, methyl ethyl ketone, and isopropanol according to the volume ratio of 0.7:0.9:1. After ultrasonic dispersion, centrifuge for 1min, and its rotating speed is 5000rpm. Discard the supernatant;

[0031] (2)Use absolute ethanol to ultrasonically disperse the sample treated in step (1), centrifuge for 1min at a speed of 5000rpm, and discard the supernatant;

[0032] (3) Add a concentration of 30g / L fluorine-containing surfactant solution to the sample treated in step (2), after ultrasonic dispersion, drop the sample on a copper grid coated with a Formova film, dry it under a 250W infrared lamp, Gold was plated in the sputtering apparatus to increase the conductivity for easy observation, the purity of the gold target was 99.999%, and the coating was 25mA for 40s.

[...

Embodiment 2

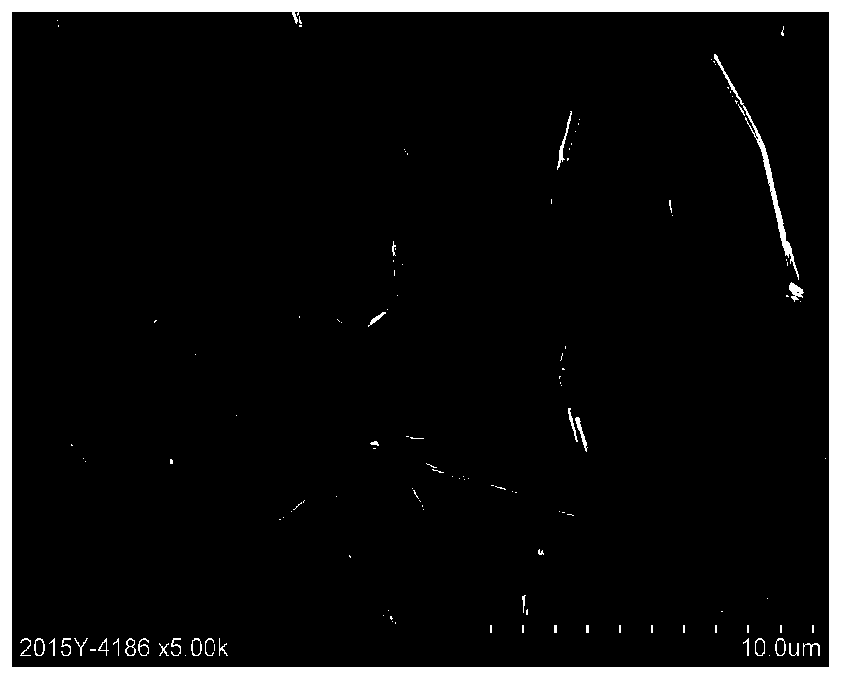

[0035] Embodiment 2: Silver behenate crystal morphology detection process

[0036] (1) Prepare a mixed solution of silver behenate crystals with a concentration of 55g / L. The solvent of the mixed solution is acetone, methyl ethyl ketone, and isopropanol according to the volume ratio of 0.8:0.9:1. After ultrasonic dispersion, centrifuge for 3min, and its rotating speed is 10000rpm. Discard the supernatant;

[0037] (2)Use absolute ethanol to ultrasonically disperse the sample treated in step (1), centrifuge for 3min at a speed of 10000rpm, discard the supernatant;

[0038] (3) Add the fluorosurfactant solution with a concentration of 60g / L to the sample treated in step (2). After ultrasonic dispersion, the sample is dropped on a copper grid coated with a Formova film, dried under a 250W infrared lamp, and dried under ion Gold was plated in the sputtering apparatus to increase the conductivity for easy observation, the purity of the gold target was 99.999%, and the coating was ...

Embodiment 3

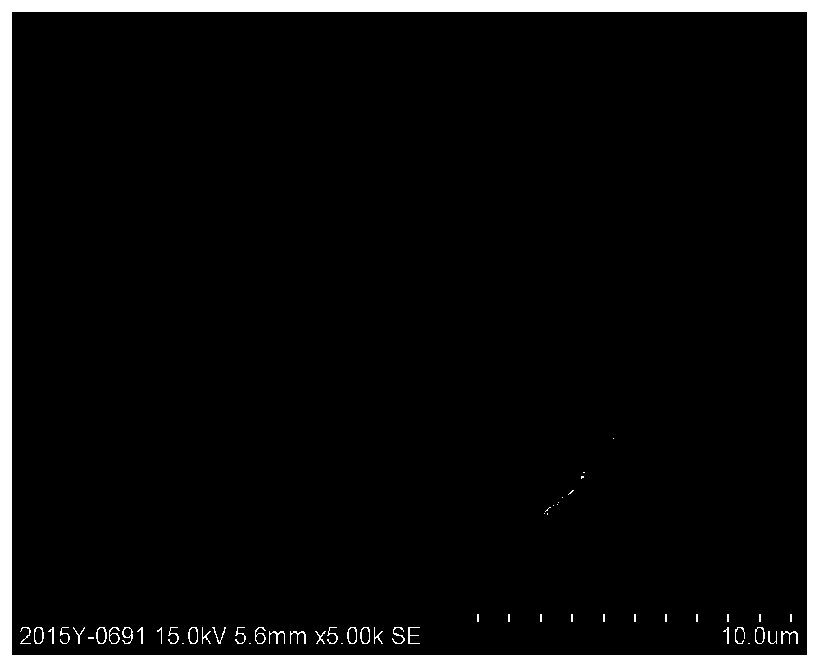

[0041] Embodiment 3: Silver behenate crystal morphology detection process

[0042] (1) Prepare a mixed solution of silver behenate crystals with a concentration of 60g / L. The solvent of the mixed solution is acetone, methyl ethyl ketone, and isopropanol according to the volume ratio of 0.9:1:1.1. After ultrasonic dispersion, centrifuge for 5 minutes, and its rotating speed is 15000rpm. Discard the supernatant;

[0043] (2)Use absolute ethanol to ultrasonically disperse the sample treated in step (1), centrifuge for 5min at a speed of 15000rpm, and discard the supernatant;

[0044] (3) Adding a concentration of 80g / L fluorine-containing surfactant solution to the sample processed in step (2), after ultrasonic dispersion, the sample is dropped on a copper grid coated with a Formova film, dried under a 250W infrared lamp, and placed in an ion Gold was plated in the sputtering apparatus to increase the conductivity for easy observation, the purity of the gold target was 99.999%, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com