Oil circuit for oil pump and diesel-powered motor vehicle

A diesel engine and oil circuit technology, applied in the direction of machine/engine, mechanical equipment, engine components, etc., can solve the problems of poor low-speed oil supply performance of oil pump oil circuit, difficult processing of zero-fuel throttle valve, complicated oil pump oil circuit, etc. Achieve the effect of improving oil supply performance, reducing use cost, manufacturing and processing difficulty, and improving operating stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

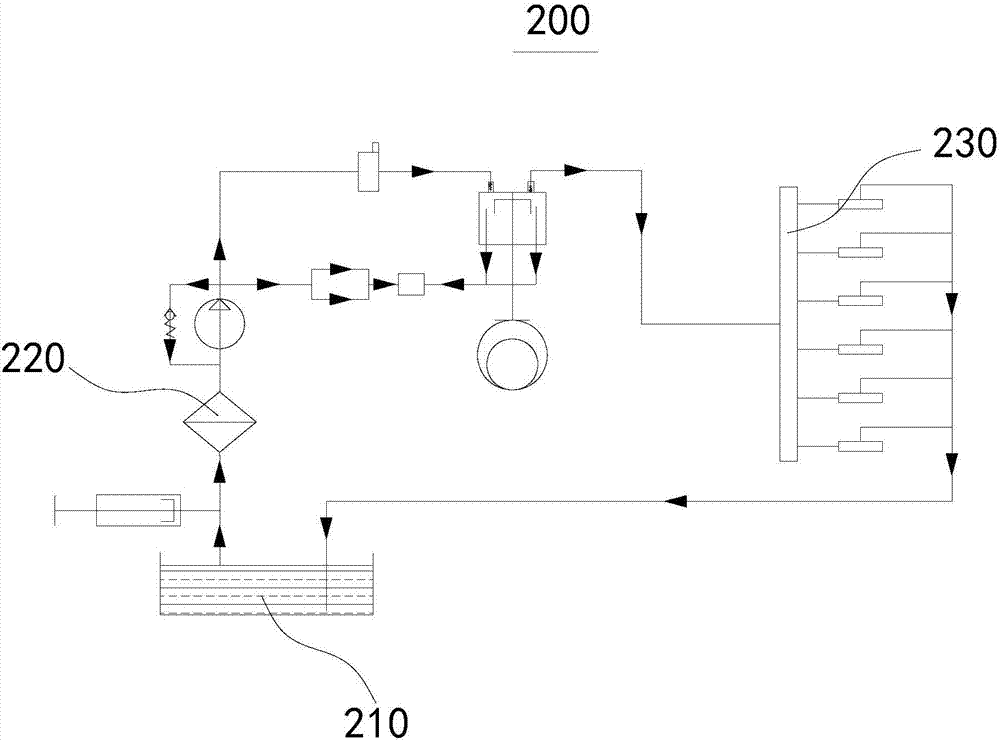

[0050] Please refer to figure 1 , figure 1 The specific structure of the oil pump oil circuit 200 provided in the embodiment is shown. From figure 1 It can be seen from the figure that the oil pump oil circuit 200 includes an oil tank 210 , an oil delivery pump 220 and a common rail pipeline 230 connected in sequence. And the flow direction of the fuel in the oil pump oil passage 200 is shown by the arrow in the figure.

[0051] It should be noted that the oil pump oil circuit 200 is used for a light diesel engine to ensure the oil supply stability and accuracy of the oil delivery pump 220 . Secondly, the load of the oil delivery pump 220 is reduced, and the oil supply capacity and reliability of the oil delivery pump 220 at low speeds are improved.

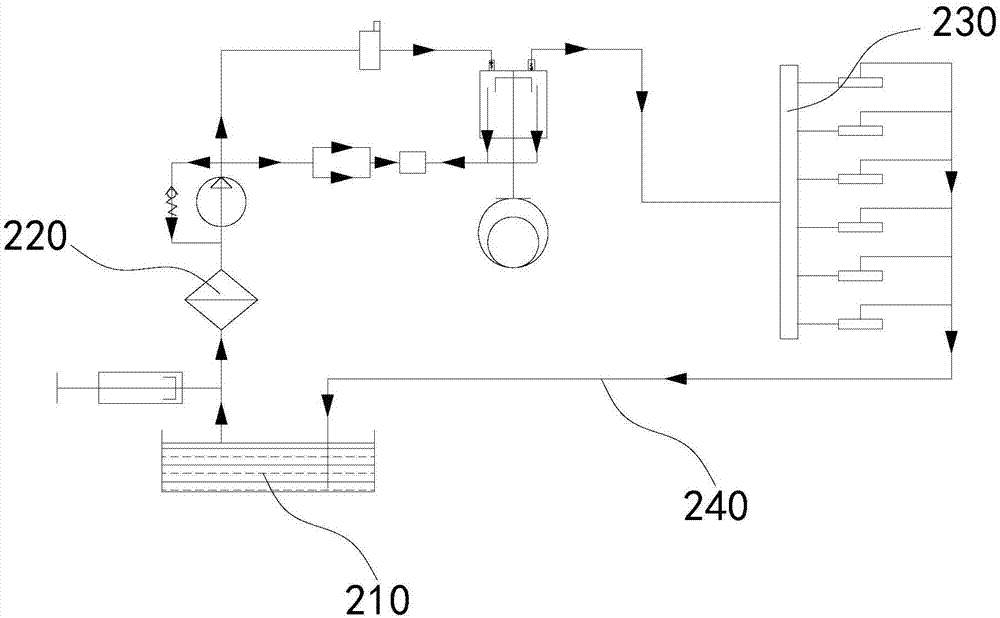

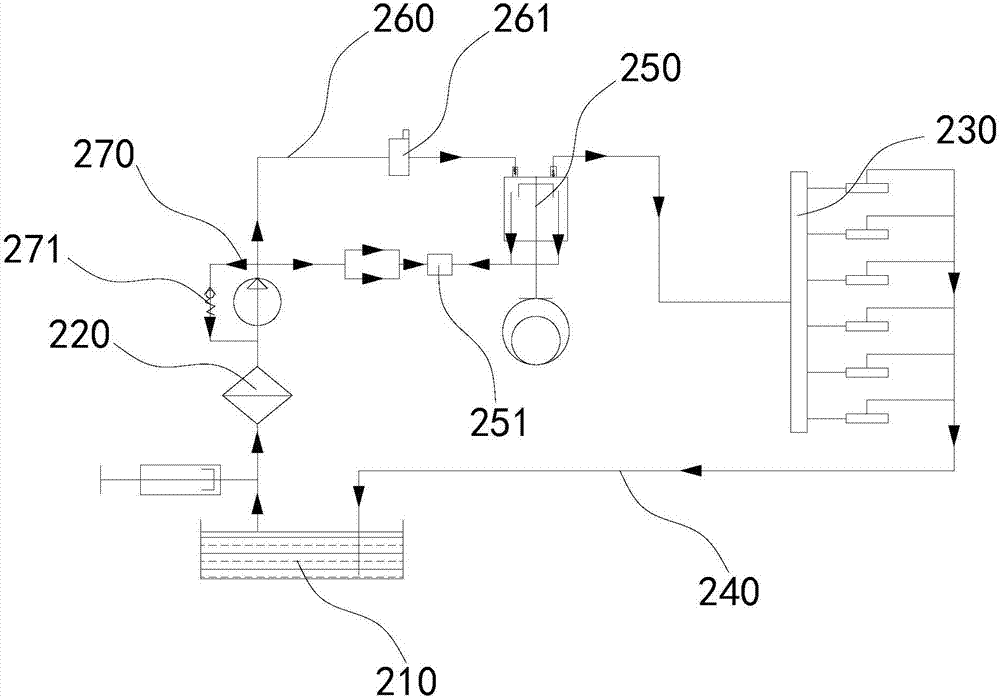

[0052] Specifically, please refer to figure 2 , the fuel tank 210 , the fuel delivery pump 220 and the common rail pipeline 230 are connected in sequence, and the common rail pipeline 230 is connected with an oil return pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com