Multi-purpose dehydrogenation reaction device

A reaction device and multi-purpose technology, applied in chemical/physical processes, chemical instruments and methods, etc., can solve the problems of high cost, failure to maximize the use of reactors, complex structure, etc., and achieve strong applicability, compact structure, Versatile Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below with reference to the accompanying drawings and examples.

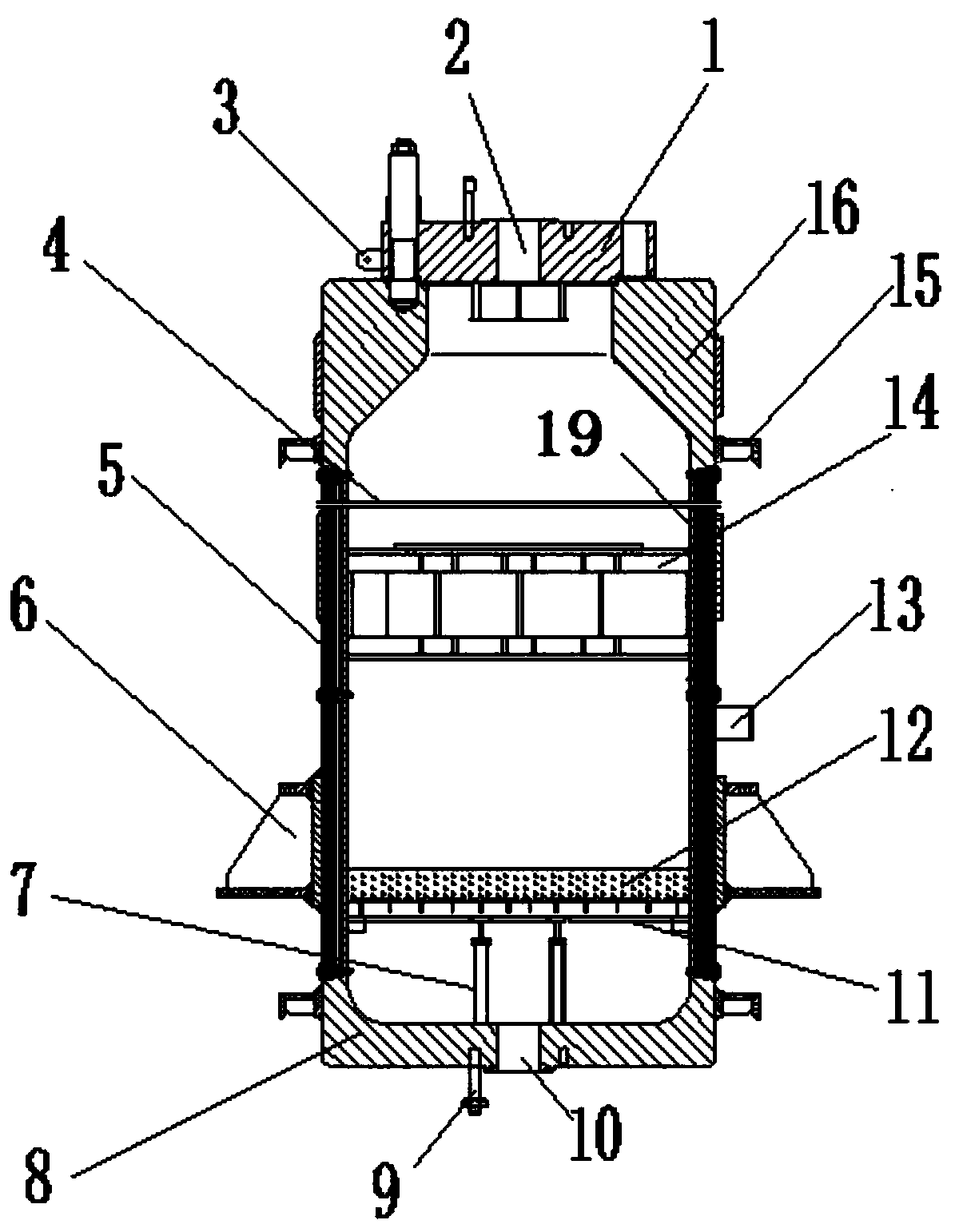

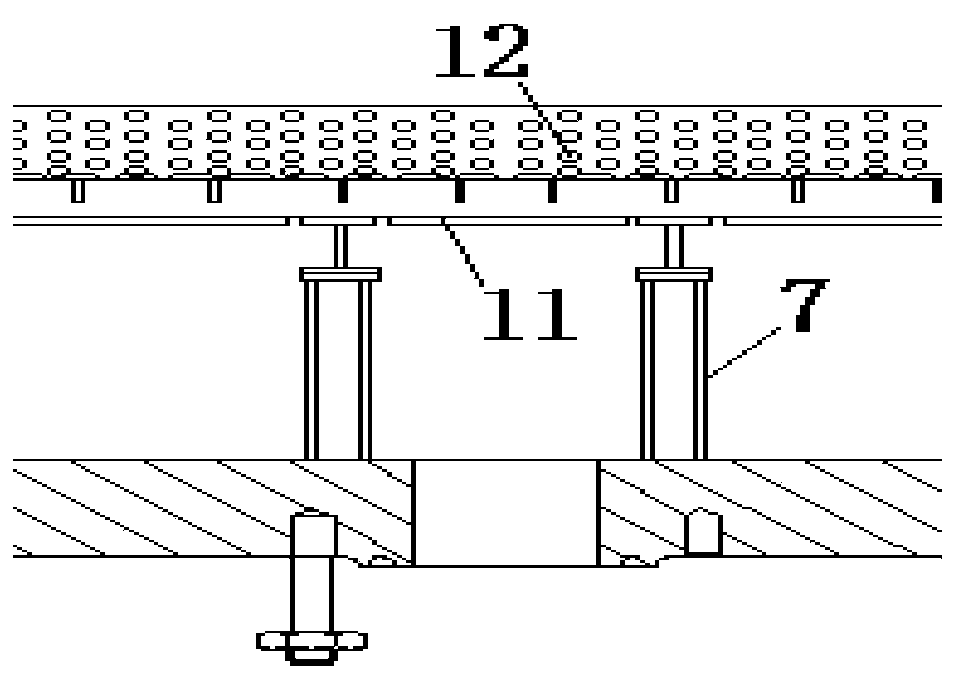

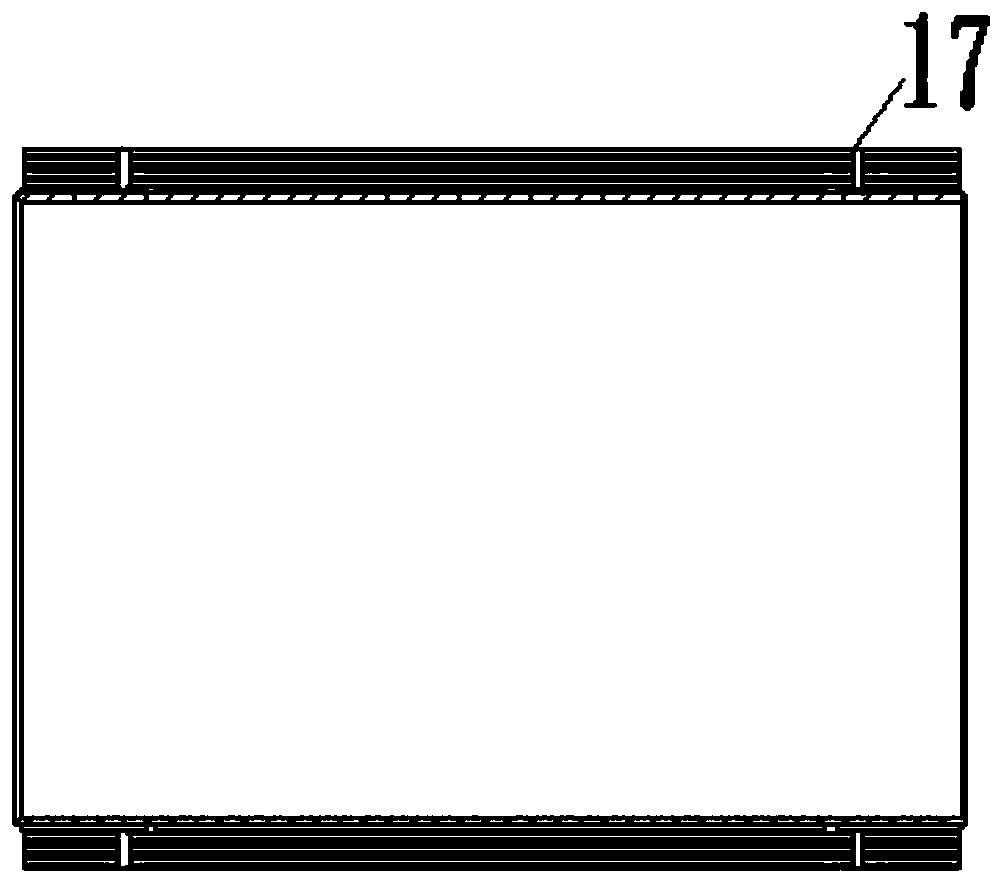

[0021] Such as figure 1 , image 3 As shown: a multi-purpose dehydrogenation reaction device, including a top cover 1, a reactant inlet 2 is arranged in the middle of the top cover 1, and an upper head 16 and a bottom bottom are symmetrically arranged on both sides of the bottom of the top cover 1. The head 8, the upper head 16 and the lower head 8 are fixedly connected by the cylinder section 5; the upper and lower ends of the cylinder section 5 are respectively provided with through holes 17, and the through holes 17 at the upper end are provided with a wire mesh defoamer device 14, steam input pipe 4 is arranged above the screen demister 14; the through hole 17 communicates with the gas riser 19 arranged on the wire mesh demister 14; The bed 11, the catalyst bed 11 is supported by the catalyst bed support 7; the bottom of the lower head 8 is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com