Silk fibroin sponge and preparation method thereof

A technology of silk protein and silk protein solution, which is applied in the fields of medical formula, medical science, prosthesis, etc., and can solve the problems of silk protein precipitation and uneven porous sponge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] Thus, the application provides the preparation method of the above-mentioned silk protein sponge, comprising the following steps:

[0031] A), the silk protein aqueous solution is sealed and cultivated and then mixed with the highly crystalline silk protein nanofiber solution to obtain a mixed solution;

[0032] B), the mixed solution is frozen and then freeze-dried to obtain silk protein sponge.

[0033] In this application, a small amount of highly crystalline silk protein nanofiber is used as an inducer, mixed with a treated silk protein solution, and then sequentially frozen and freeze-dried to obtain a silk protein sponge.

[0034] In the process of preparing the silk protein sponge, the applicant first sealed and cultivated the silk protein aqueous solution; after the sealed cultivation, the conformation of the random silk protein gradually changed to an intermediate state. The silk protein is a silk protein well known to those skilled in the art, and there is no...

Embodiment 1

[0047] (1) Slowly concentrate the ordinary silk protein solution in the range of 40-60°C to obtain a solution with a concentration of about 10%;

[0048] (2) Transfer the solution to normal temperature and continue to concentrate to about 20%, during which the silk protein transforms into metastable nanoparticles;

[0049] (3) The concentrated solution is diluted with water to 0.5%-2%, placed at 60° C. and incubated in a sealed manner until obtaining highly crystalline silk protein nanofibers.

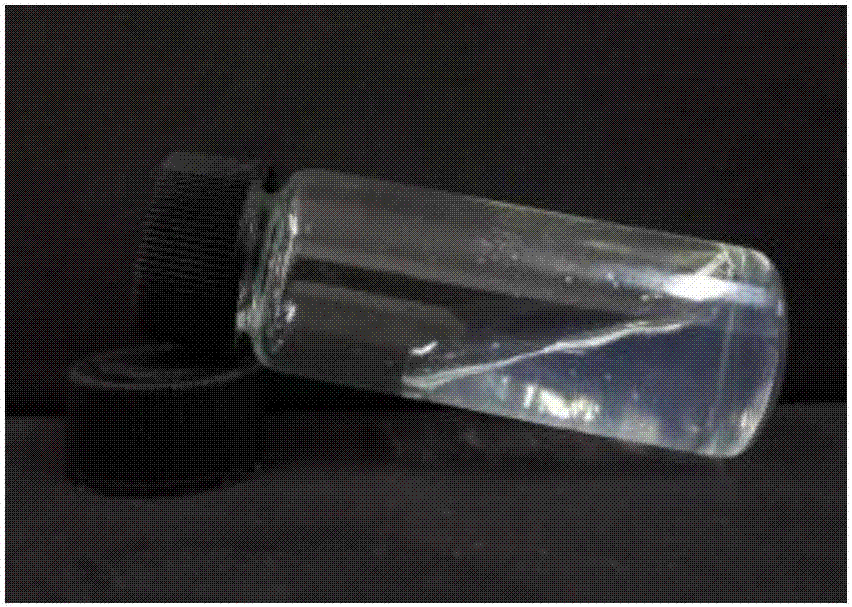

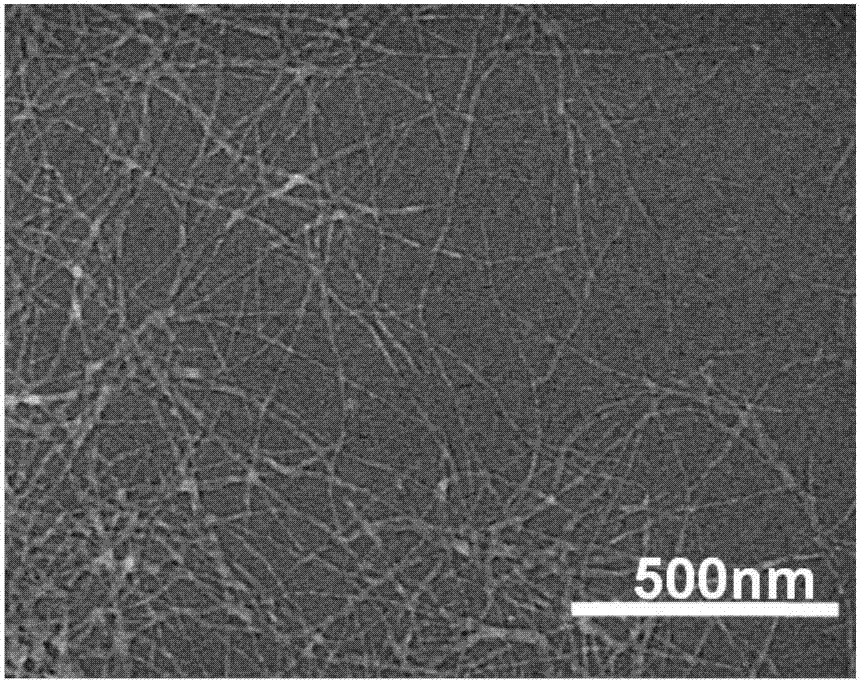

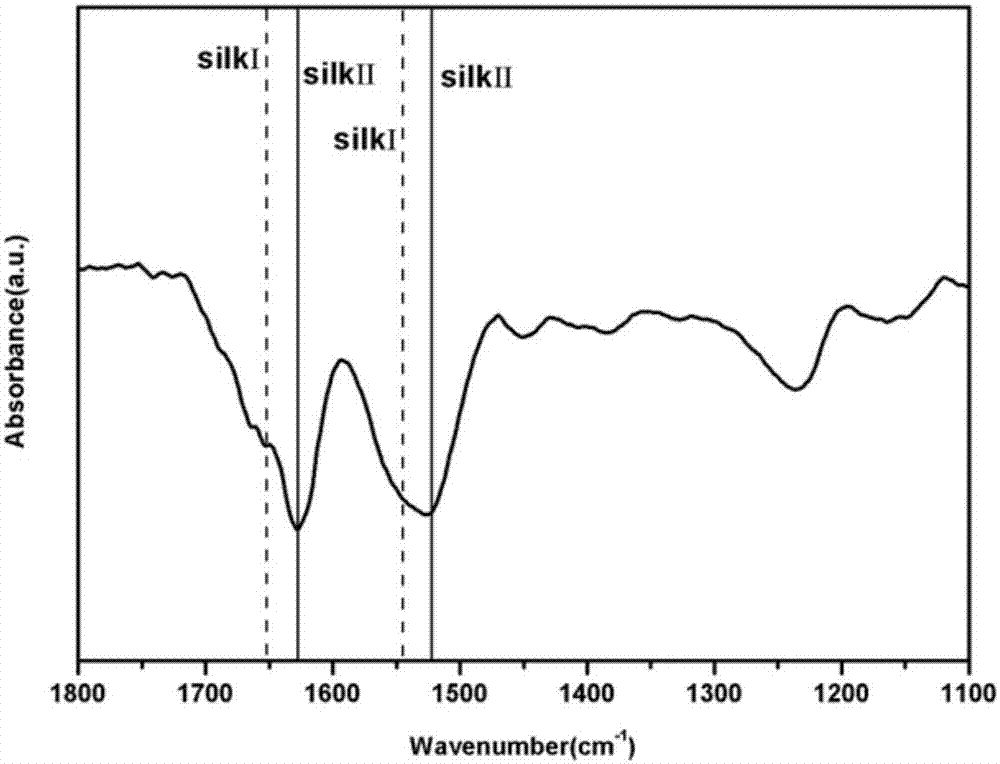

[0050] figure 1 and figure 2 Respectively, the macroscopic and microscopic diagrams of the highly crystalline silk protein nanofibers prepared in this example, image 3 Infrared spectrum of the nanofibers prepared for this example; as can be seen from the figure, the highly crystalline silk protein nanofibers prepared in this implementation are in a solution state, the fiber diameter is between 10 and 20 nm, and the length is between 200 nm and 3 μm. The infrared spectrum shows that...

Embodiment 2

[0053] (1) After a certain concentration of common silk protein solution was sealed and incubated at 40°C for 48 hours, it was mixed with the high crystallization silk protein nanofiber solution. The mass ratio of high crystallization silk protein nanofiber to common silk protein was 1:40, and two kinds of A mixed aqueous solution of silk protein and injected into the mould;

[0054] (2) freezing the silk protein nanofiber solution injected into the mold at -7°C for 24 hours to form ice;

[0055] (3) Place the frozen ice-like substance in a lyophilizer with a cold trap temperature of -63° C., and freeze-dry for 48 hours to obtain a water-insoluble silk protein sponge.

[0056] Figure 4 and Figure 5 The high-power and low-power electron micrographs of the porous silk protein sponge material prepared in this example are respectively. It can be seen from the figure that the porous silk protein sponge prepared in this example has a pore diameter between 100 and 200 μm, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com