Chemically resistant multilayered coating for a measuring device used in process engineering

A multi-layer coating, chemical-resistant technology, used in measuring devices, detecting fluid flow by measuring differential pressure, displaying liquid level indicators by pressure measurement, etc., can solve problems such as fragile and damaged coatings, and achieve good corrosion resistance protective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

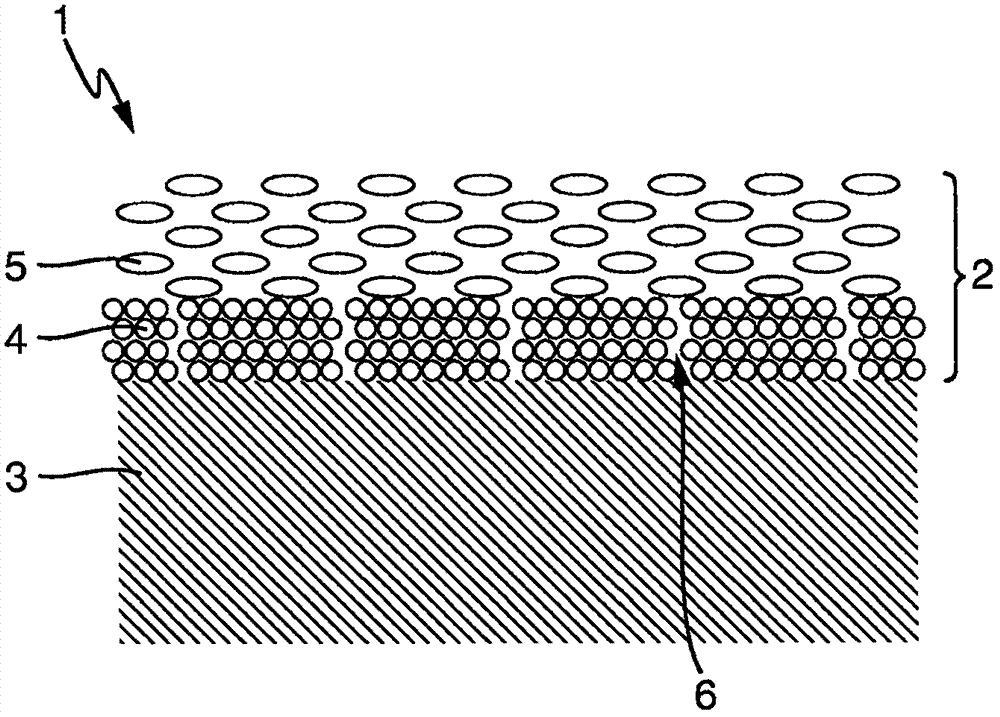

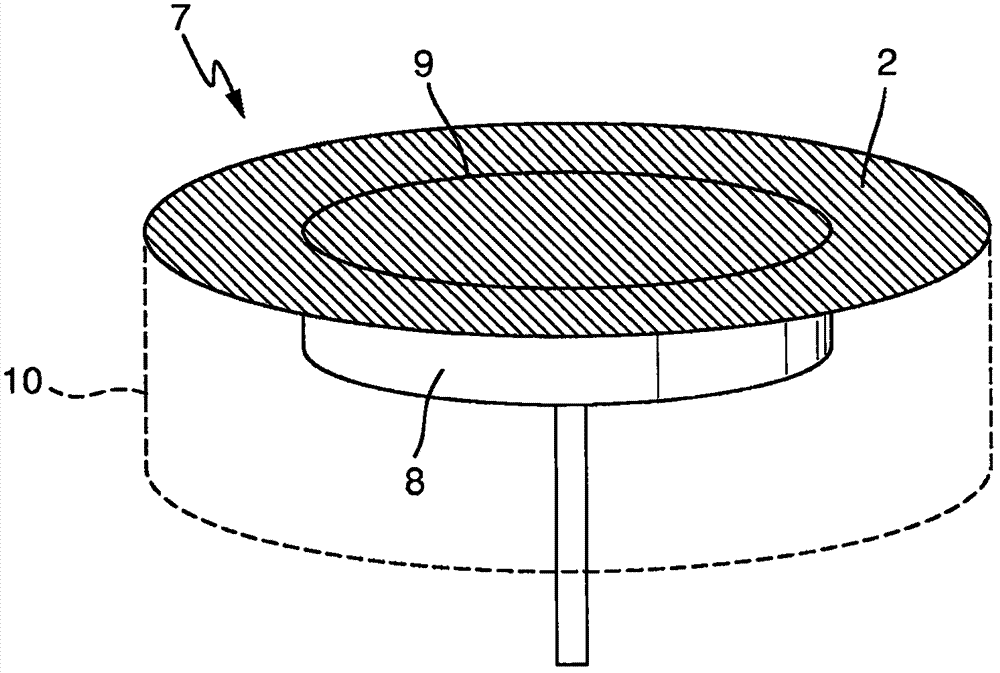

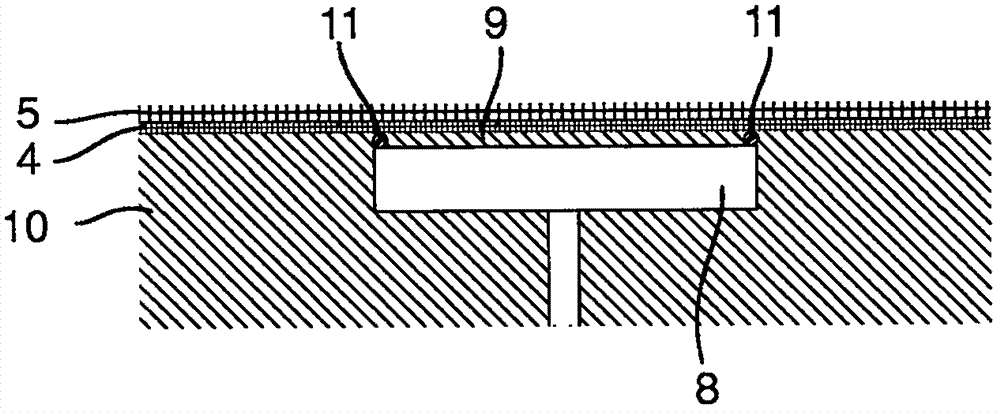

[0036] attached figure 1 A schematic diagram showing the surface of a part of a sensor unit 1 in contact with a medium, which is coated with a multilayer coating 2 according to the invention. For the sake of clarity, the part 3 of the sensor unit which is in contact with the medium is represented as a rectangle. The multilayer coating 2 consists of a first layer 4 and a second layer 5 arranged thereon.

[0037] As already mentioned, the first layer can consist of metals such as gold, platinum, silver or tantalum or so-called hard materials such as SiC, DLC, Al 2 o 3 , SiO 2 or BN composition. Depending on the application, different materials and correspondingly also different coating methods are advantageous, for example electro-phase deposition, physical vapor deposition processes (PVD) or even CVD methods. The basic principles are known from various publications and are therefore not explained in detail here.

[0038] In particular, the CVD method, in which solid parts...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com