Device for cooling a shaft furnace distribution chute support journals

A trunnion and chute technology, which is used in the field of equipment for cooling shaft furnace distribution chute support trunnions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

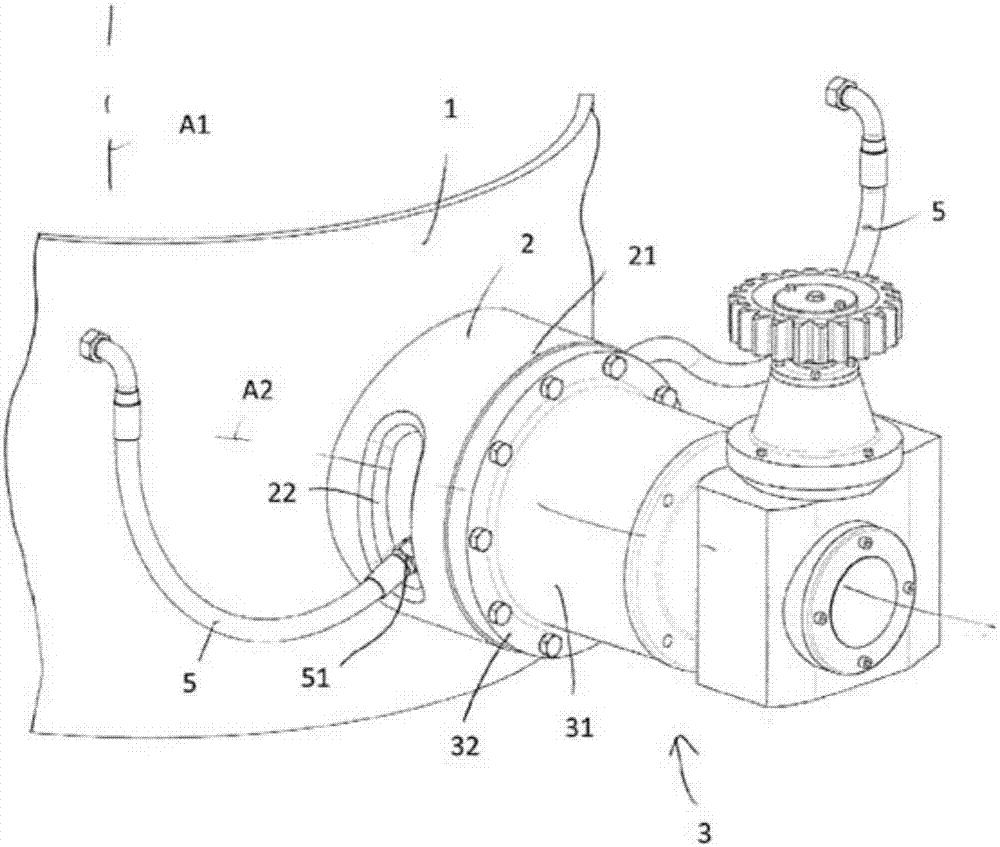

[0020] figure 1 The drawing of the figure shows the shell 1 of the blast furnace charging device, which can be rotated about the vertical axis A1 of the blast furnace, and the bearing 2 is attached to the shell, and the end of the bearing has a drive for pivoting about the horizontal axis A2 The reduction gear unit 3 of the chute (not shown). The reduction gear unit 3 includes a crankcase 31 fixed to the outer end 21 of the bearing 2 by a flange (flange) 32 .

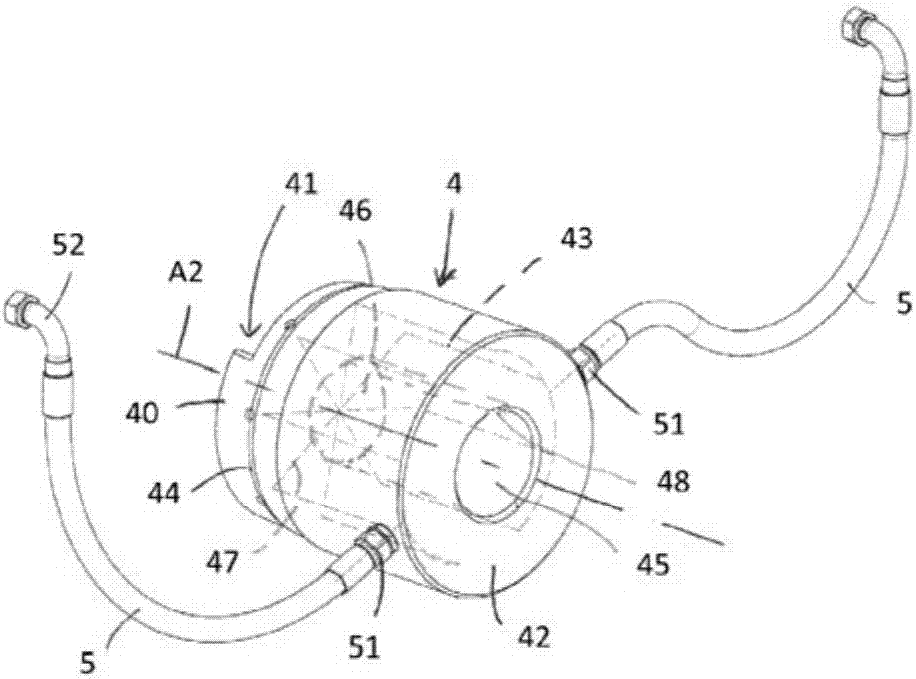

[0021] figure 2 The trunnion 4 for supporting the chute shown in includes a housing 41 oriented towards the inner end 40 of the trunnion, towards the axis A1, the housing being arranged to accommodate the support lugs of the chute, the chute's The support lug is held rigidly in the receptacle in a manner known per se. The other end of the trunnion 42 is rigidly connected to the output shaft of the reduction gear unit 3 , which is rotatably supported and guided in the crankcase 31 . For this purpose, the trunnion co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com