Titanium slab for hot rolling, and production method therefor

A manufacturing method and casting slab technology, applied in the direction of metal rolling, coating, metal material coating technology, etc., can solve the problems of deterioration of yield rate, increase of cost, and hindrance to the practical application of titanium casting slabs, so as to achieve the improvement of yield rate, The effect of reducing the heating time

Active Publication Date: 2017-08-18

NIPPON STEEL CORP

View PDF4 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In order to remove surface flaws generated during hot rolling, it is necessary to use pickling as a subsequent process to increase the amount of melting on the surface of the hot-rolled material, and the yield rate deteriorates accordingly, and there is concern about cost increases

[0005] Therefore, for titanium ingots manufactured by electron beam melting method and plasma arc melting method, on the one hand, it is expected to improve the cost by omitting blanking processes such as rough rolling and forging. , which hinders the practical application of titanium billets that omit the billet opening process

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

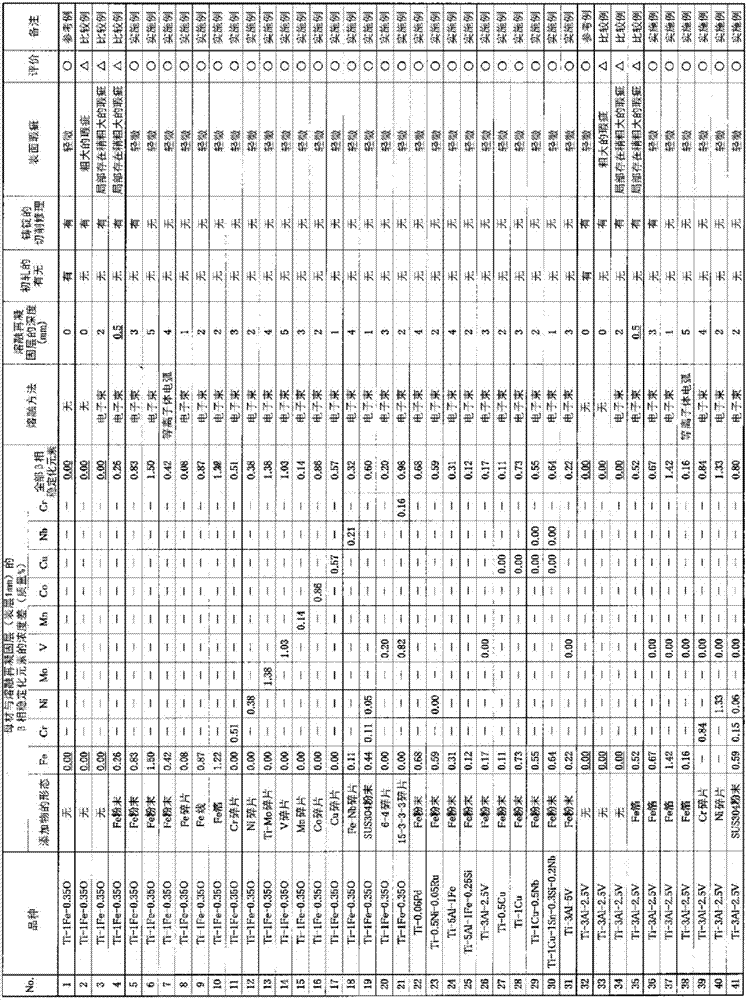

[0043] Hereinafter, the present invention will be further described in detail based on examples.

[0044] [Table 1]

[0045]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Login to View More

Abstract

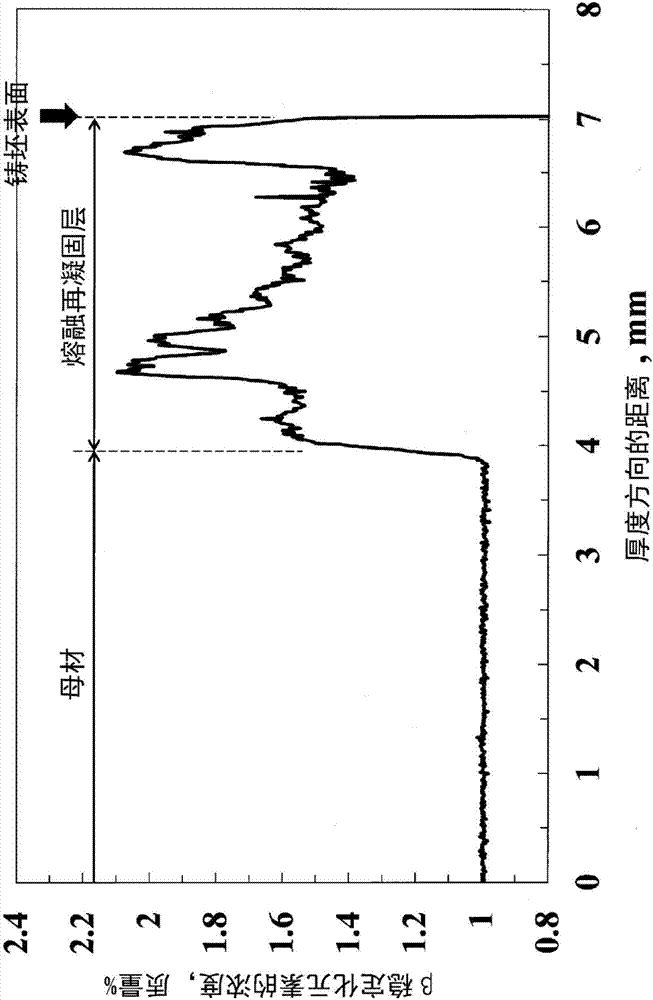

A melted and resolidified layer, which has a depth of at least 1 mm and is obtained by adding, melting, and resolidifying at least one Beta-phase-stabilizing element, is provided to the surface to be rolled of a titanium slab comprising a titanium alloy produced using an electron beam melting method or a plasma arc melting method. The average concentration of the Beta-phase-stabilizing element in a range up to a depth of 1 mm is at least 0.08 mass% but not more than 1.50 mass% higher than the concentration of the Beta-phase-stabilizing element in the parent metal. Powder, chippings, wire, and foil are used as raw materials which include the Beta-phase-stabilizing element. Furthermore, electron beam heating and plasma arc heating are used as means for melting the surface layer.

Description

technical field [0001] The present invention relates to a method for producing a titanium slab for hot rolling including a titanium alloy, and in particular to a titanium slab capable of maintaining a good surface shape after hot rolling even if blanking steps such as blooming and forging are omitted, and a method for producing the same. Background technique [0002] Titanium materials are usually made of sponge titanium and titanium waste as raw materials, and are smelted by non-consumable electrode arc melting method, electron beam melting method, plasma arc melting method, etc., so as to form titanium ingot (titanium billet). In the non-consumable arc melting method, a compact obtained by press-molding sponge titanium is used as an electrode, and the electrode and the mold are subjected to arc discharge to melt the electrode itself, and cast in the mold to obtain an ingot. Therefore, the discharge between the mold and the electrodes must be performed uniformly, so that th...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C23C26/00B21B1/02B21B3/00B22D21/06B22D29/00C22C14/00

CPCB22D21/06B22D29/00B21B1/02B21B3/00C22C14/00C23C26/00C22C1/02B21B1/22B21B2001/225

Inventor 立泽吉绍国枝知德森健一藤井秀树高桥一浩

Owner NIPPON STEEL CORP

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com