Atomization components and electronic cigarettes

An atomization component and electronic cigarette technology, which is applied in the field of electronic cigarettes, can solve problems such as damage to the control circuit board, offset of the heating wire, damage to the electronic cigarette, etc., and achieve the effects of avoiding short circuit, avoiding burning, and increasing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

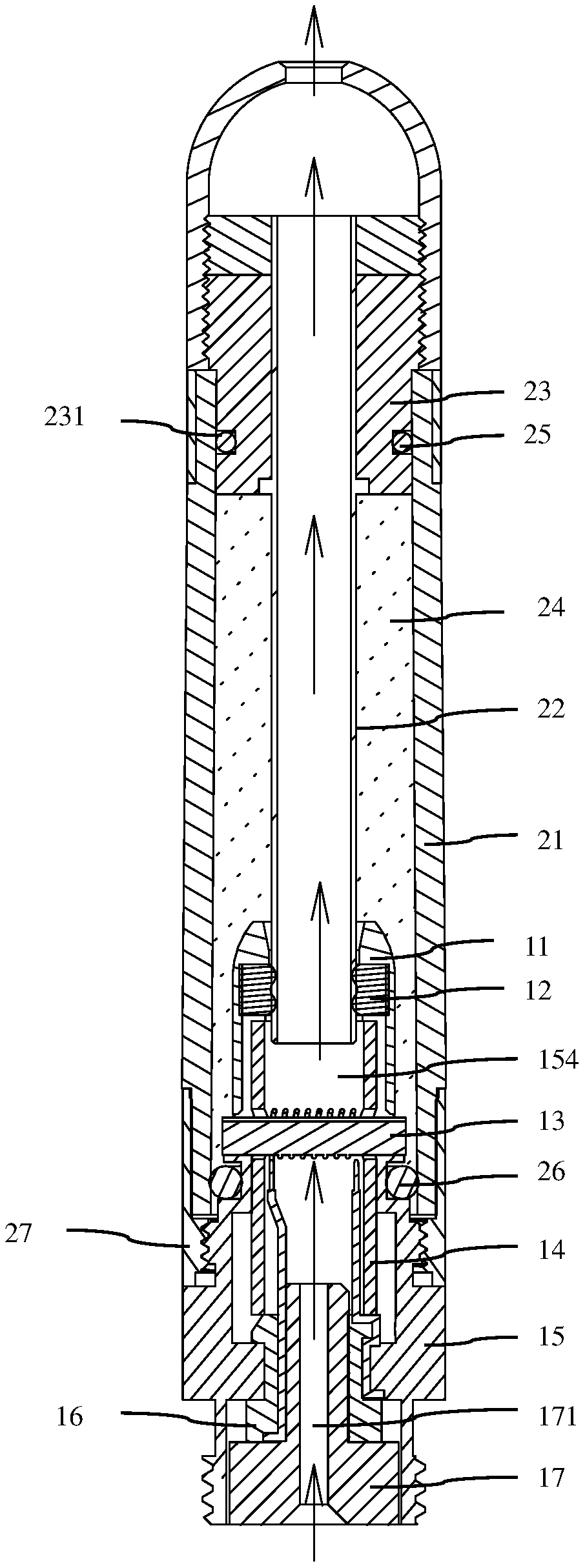

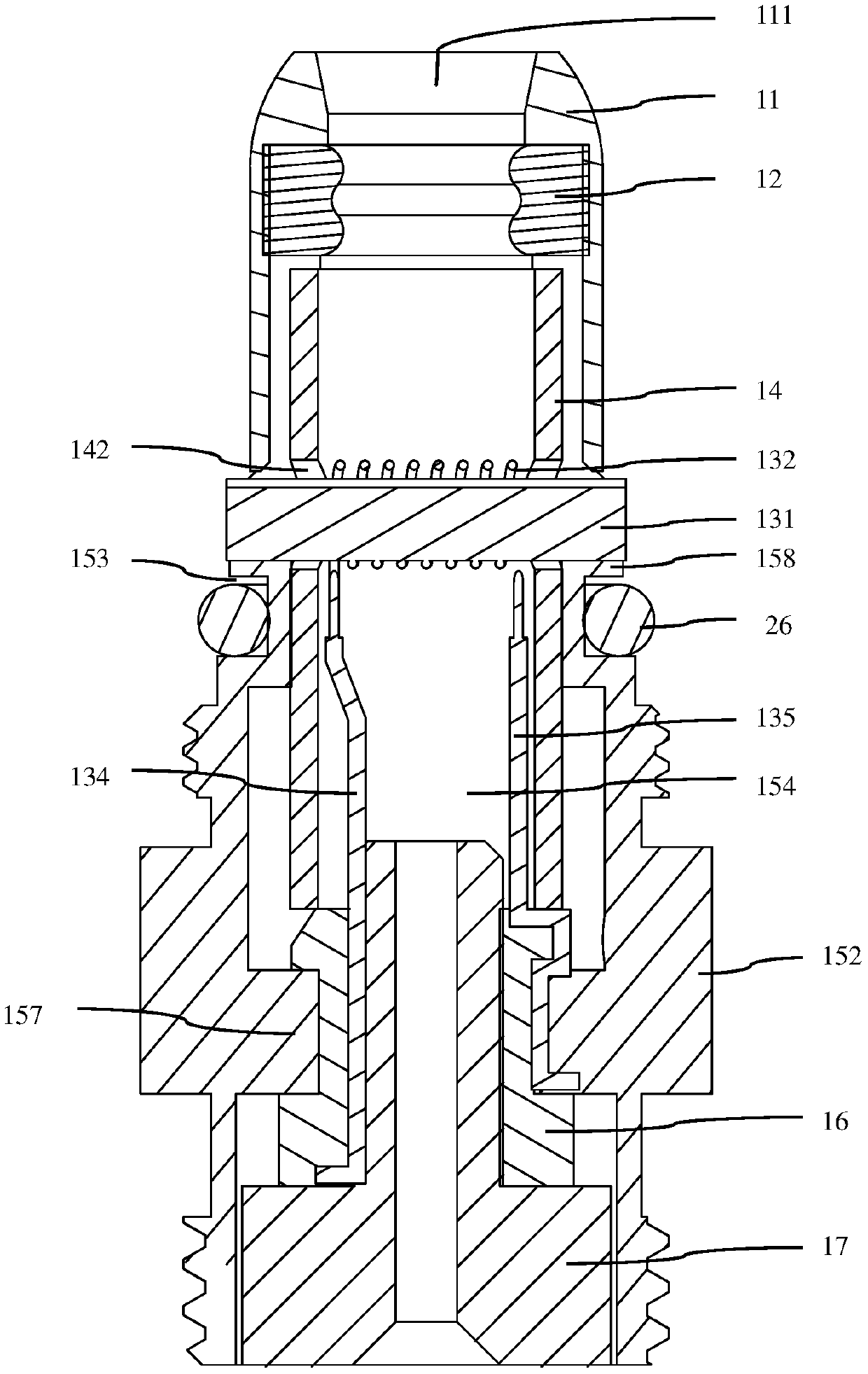

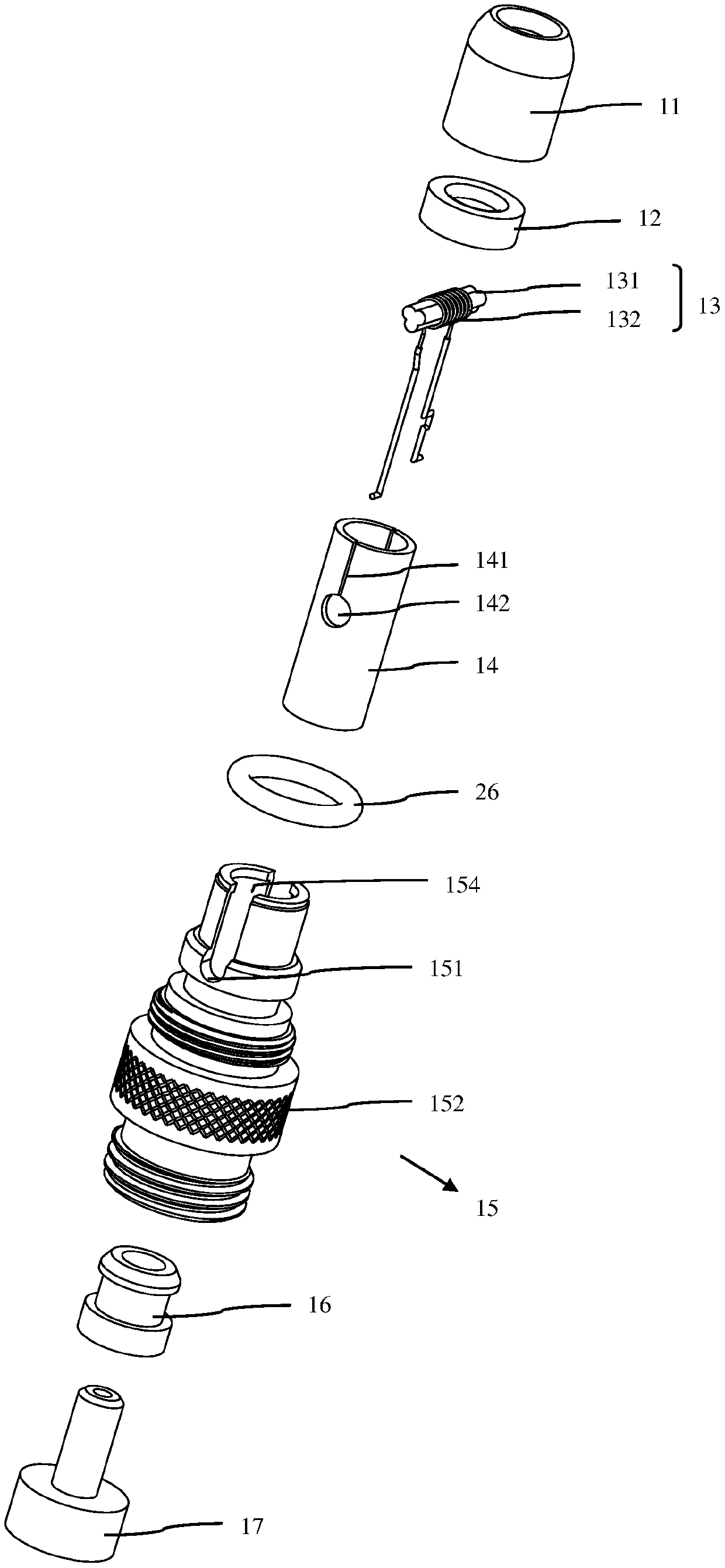

[0040] Example 1: Please refer to figure 1 , figure 2 , image 3 and Figure 4 .

[0041] The atomization assembly provided by the present invention includes an oil cup assembly and an atomization core arranged in the oil cup assembly, wherein the oil cup assembly includes an atomization sleeve 21, a vent pipe 22, an oil separator 23 and a suction nozzle assembly, and The atomizing core, the atomizing sleeve 21 , the air pipe 22 and the oil separator 23 form an oil storage chamber 24 for storing e-liquid.

[0042]The atomizing sleeve 21 is a hollow tubular structure, one end of which is detachably connected to the atomizing core through a connecting piece 27, and the other end is detachably connected to the oil separator 23 and the nozzle assembly respectively. In this embodiment, the oil separator 23 is inserted into the port of the atomizing sleeve 21 to prevent the liquid from leaking out, and the suction nozzle assembly is sleeved outside the atomizing sleeve 21 and i...

Embodiment 2

[0066] Example 2: Please refer to Figure 5 , and combined with figure 1 , figure 2 and image 3 .

[0067] The difference between this embodiment and the first embodiment is that the insulating tube 14 is arranged coaxially with the inner cavity of the atomizing seat 15, the cutout 141 extends from the fixing hole 142 to the outer wall surface of the insulating tube 14, and the direction of the cutout 141 is the same as that of the insulating tube The axes of 14 are vertical, that is, the cutout 141 is arranged horizontally.

Embodiment 3

[0068] Example 3: Please refer to Figure 6 , and combined with figure 1 , figure 2 and image 3 .

[0069] The difference between this embodiment and the previous embodiments is that the insulating tube 14 is arranged coaxially with the inner chamber of the atomizing seat 15, the cutout 141 extends from the fixing hole 142 to the side wall of the insulating tube 14, and the direction of the cutout 141 is consistent with the insulation The axial directions of the tubes 14 intersect, that is, the cutouts 141 are arranged obliquely.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com