AlInGaN-based green and yellow light-emitting diode epitaxial structure

A technology of light-emitting diodes and epitaxial structures, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of V-pit 4 to enhance hole injection, etc., and achieve the effect of enhancing hole injection function and improving luminous efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

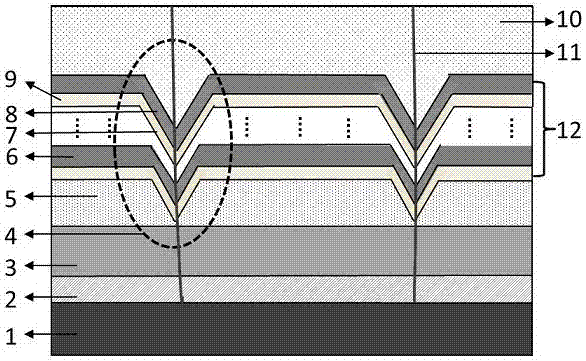

[0036] This embodiment introduces the epitaxial structure in which the starting position of the V-pit is the substrate.

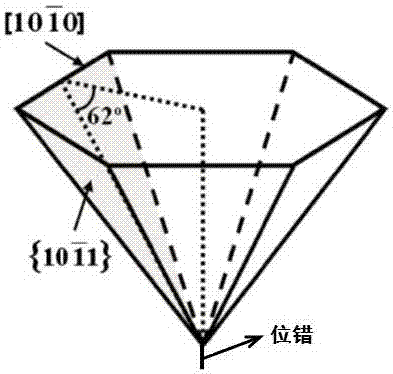

[0037] refer to Figure 5 . In the figure, 1 is the substrate, and the "process V-pit" 4 is periodically arranged on the substrate 1, and the schematic diagram of the projection of the "process V-pit" 4 on the upper surface of the substrate 1 is as follows Figure 4 shown. The buffer layer 2 is grown on the substrate 1. Due to the existence of the "process V pit" 4 on the substrate 1, a semipolar buffer layer 2 will also grow on the sidewall of the "process V pit" 4; moreover, the buffer layer 2 The growth rate on the semipolar face is less than that on the polar face. Therefore, a "process V-pit" 4 is also formed in the buffer layer 2, the size of which is larger than that of the "process V-pit" 4 in the substrate 1, and the periodic arrangement of the "process V-pit" 4 of the substrate 1 is inherited. . Similarly, growing the N-type AlInGaN layer 3 o...

Embodiment 2

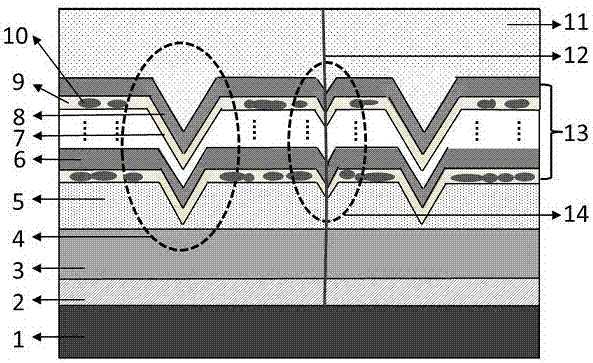

[0039] Compared with Example 1, the substrate 1 is changed to have no "process V-pit" 4 structure, that is, the "process V-pit" 4 starts in the buffer layer 2; the epitaxial structure refers to Figure 6 . In this epitaxial structure, the "process V-pit" 4 needs to be introduced after the buffer layer 2 is grown. Therefore, the entire epitaxial structure needs to be completed by means of secondary epitaxy.

Embodiment 3

[0041] Compared with Example 2, the buffer layer 2 is changed to have no "process V-pit" 4 structure, that is, the "process V-pit" 4 starts in the N-type AlInGaN layer 3; the epitaxial structure refers to Figure 7 . The epitaxial structure needs to grow the N-type AlInGaN layer 3 before introducing the "process V-pit" 4, so a secondary epitaxial method is required to complete the entire epitaxial structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com