Solar module for double-curved-surface vehicle roof and preparation method thereof

A solar cell stack, hyperboloid technology, applied in the direction of final product manufacturing, renewable energy integration, sustainable manufacturing/processing, etc., can solve the problem of reducing the reliability and safety of solar cells, affecting the visual effect of the roof appearance, air bubbles, etc. problem, to prevent hot spot effect, reduce battery rupture, reduce stress effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0074] The present invention also provides a method for preparing a solar module for a hyperboloid roof, referring to Figure 17 , which includes the following steps:

[0075] S1. Make the upper encapsulation layer and the lower encapsulation layer according to the shape of the hyperboloid roof, so that the upper encapsulation layer and the lower encapsulation layer have a curved surface adapted to the shape of the hyperboloid roof, and the curved surface is along a hyperboloid curved in a first direction and a second direction;

[0076] S2. Divide thin-film solar panels or crystalline silicon solar cells into several smaller sub-cells by laser cutting according to the shape and size of the hyperboloid roof;

[0077] S3. Arranging the sub-batteries along the first direction into several sub-battery strings, the number of sub-batteries in the sub-battery strings is ≥ 1;

[0078] S4. Lay the plurality of sub-battery strings in parallel along the second direction, and connect t...

Embodiment 1

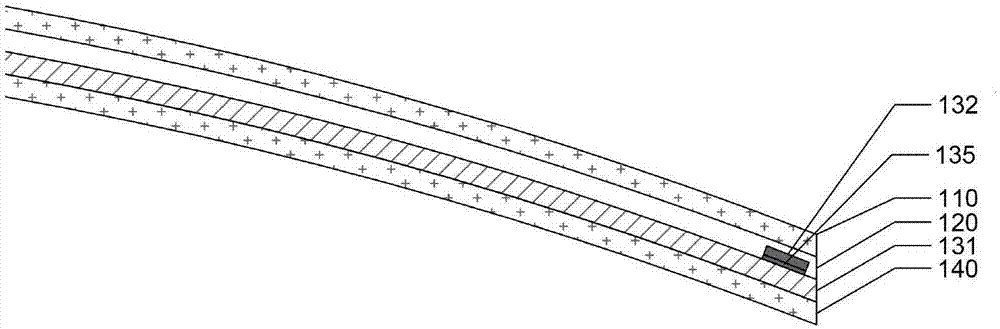

[0084] refer to Figure 1 to Figure 3 shown. image 3 is a schematic plan view of the arrangement of solar battery packs 130 along the hyperboloid roof, figure 1 is a cross-sectional view of the solar cell group 130 along a first direction, figure 2 is a cross-sectional view of the solar cell group 130 along the second direction. The solar cell group 130 is encapsulated between the upper encapsulation layer 110 and the lower encapsulation layer 140 by the adhesive film layer 120 . The solar battery pack 130 includes a sub-battery 131 , positive and negative lead wires 132 , a bus strip 133 and a junction box 134 .

[0085] In a preferred embodiment of the present invention, the upper encapsulation layer 110 is made of ultra-clear high-transparency semi-tempered glass with a thickness of 2.1 mm, and the visible light transmittance is above 90%, and the lower encapsulation layer 140 is made of glass with a thickness of 2.1 mm. Common semi-tempered glass has visible light tr...

Embodiment 2

[0101] The difference between the embodiment of the present invention and embodiment 1 is that in order to meet the lighting requirements of the glass roof, such as Figure 4 As shown, the embodiment of the present invention uses narrower thin-film sub-cell strips to widen the distance between the sub-cells 231 in the solar cell group 230. The area is a high transmittance area, and the high and low transmittance intervals are followed to achieve the effect of light transmission. In a preferred embodiment of the present invention, the width of the sub-battery 231 is preferably 35 mm, and the distance between the sub-batteries is preferably 9 mm, forming alternating light-transmitting regions in sequence. The above-mentioned structure can provide about 60W of power, and It can meet the requirement of 30% visible light transmittance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com