Capacitor apparatus

A technology for capacitors and capacitor towers, applied in the field of capacitors, can solve the problems of reducing the electric field intensity of capacitor devices, which cannot be satisfied, and achieve the effects of good economic benefit prospects, lower electric field intensity, and low production process requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

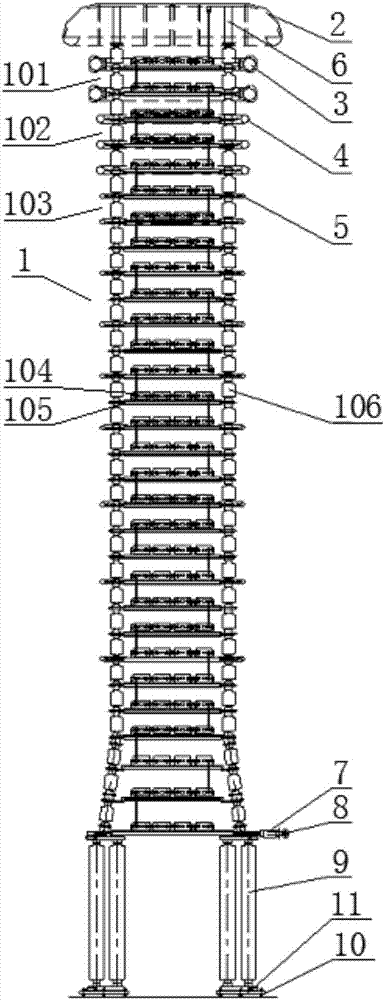

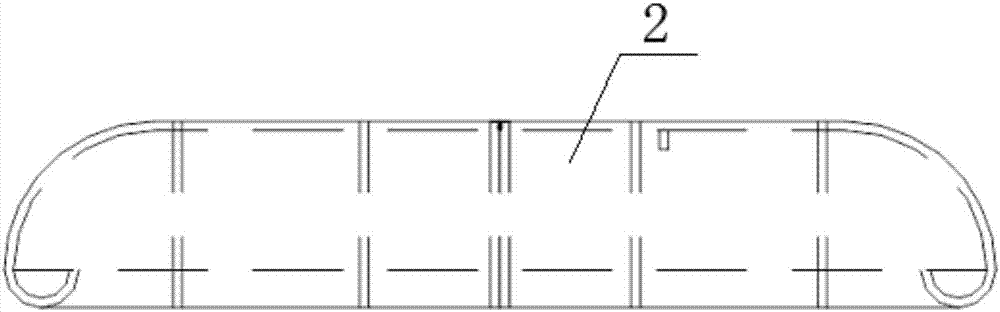

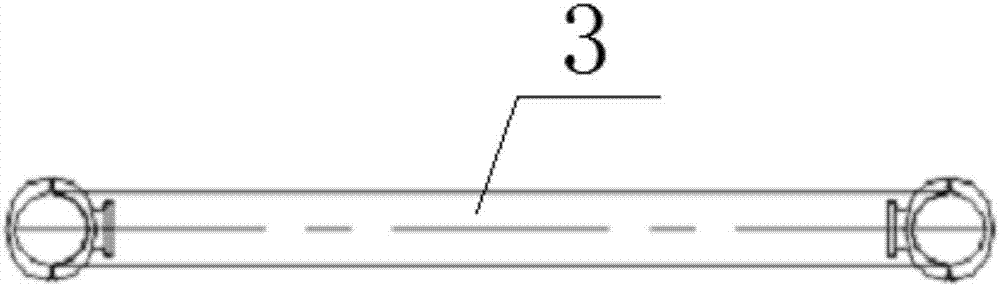

[0035] like Figure 1 to Figure 10 As shown, a capacitor device includes a capacitor tower 1 composed of a plurality of first capacitor frames 101, a plurality of second capacitor frames 102 and a plurality of third capacitor frames 103 stacked vertically from top to bottom in sequence, and a voltage equalizing cover 2. The first pressure equalizing ring 3, the second pressure equalizing ring 4 and the third pressure equalizing ring 5, the top of the capacitor tower 1 is fixed with a steel support 6, and the pressure equalizing cover 2 is covered on the steel support On the seat 6; a plurality of first capacitor frames 101 are fitted with a first equalizing ring 3; a plurality of said second capacitor frames 102 are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com