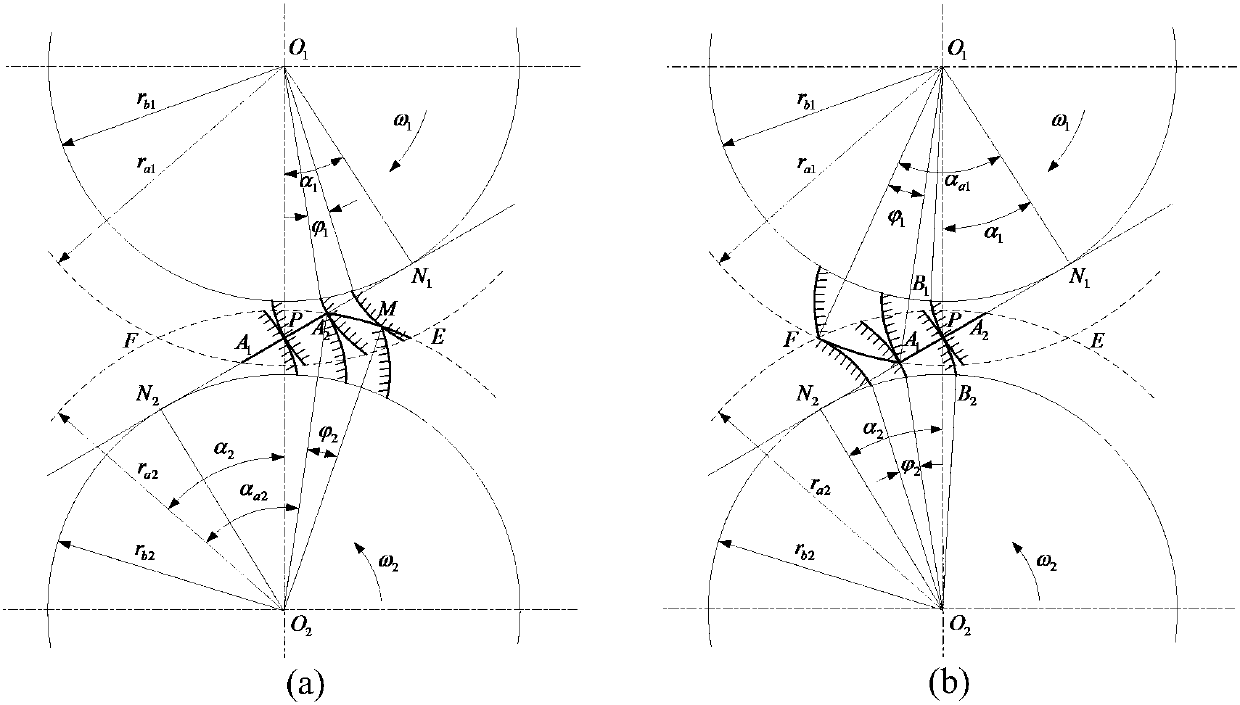

Meshing impact model with base pitch error

A meshing and base pitch technology, which is applied to elements with teeth, belts/chains/gears, portable lifting devices, etc., can solve the problem that the meaning and function of the first and second derivatives of the transmission error formula are not given, and there is no in-depth analysis. Problems such as meshing characteristics of gears with base pitch error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0069] The present invention is described below in conjunction with specific examples:

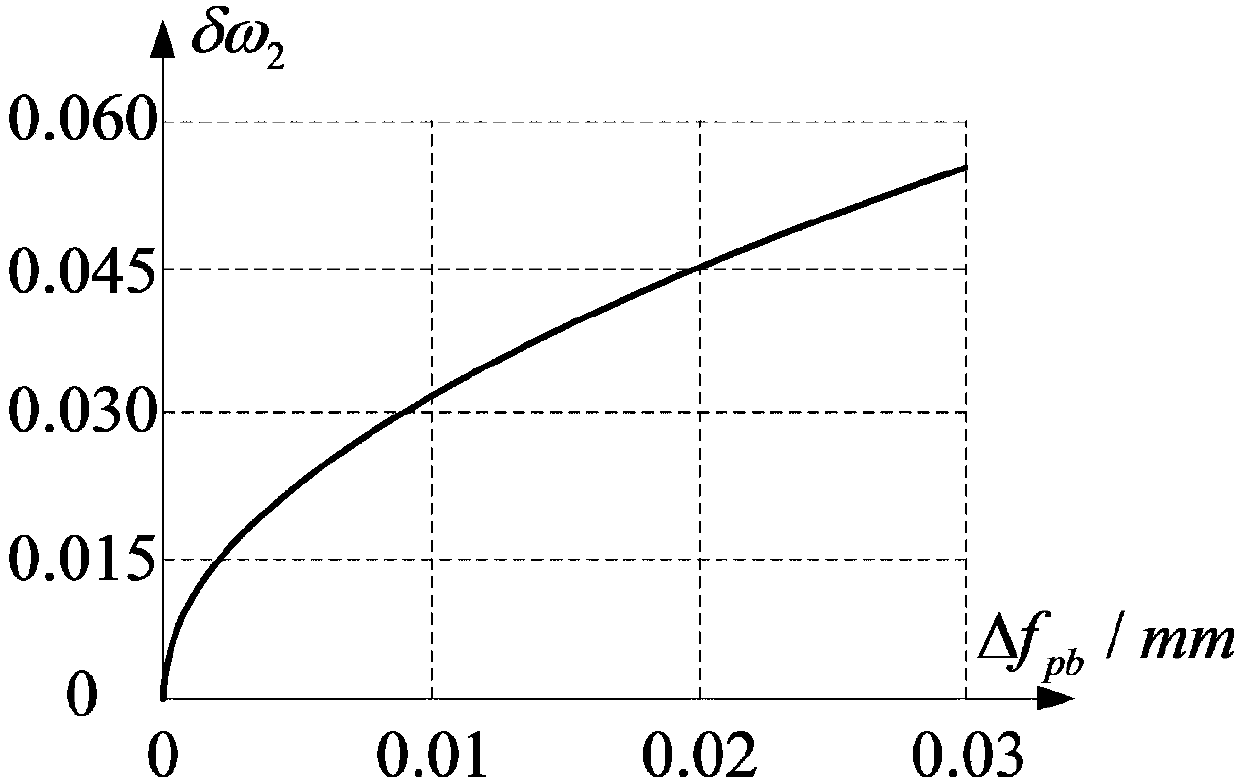

[0070] Using the number of teeth Z 1 =55 standard spur gear is used as the driving wheel, the number of teeth is Z 2 =25, base pitch error Δf pb Four spur gears of 0, 0.01mm, 0.02mm and 0.03mm are used as driven wheels. The modulus of the driving wheel and the driven wheel is m=2, and the pressure angle of the graduation circle is α=20°. Mesh impact analysis is performed separately.

[0071] (1) Bite impact analysis

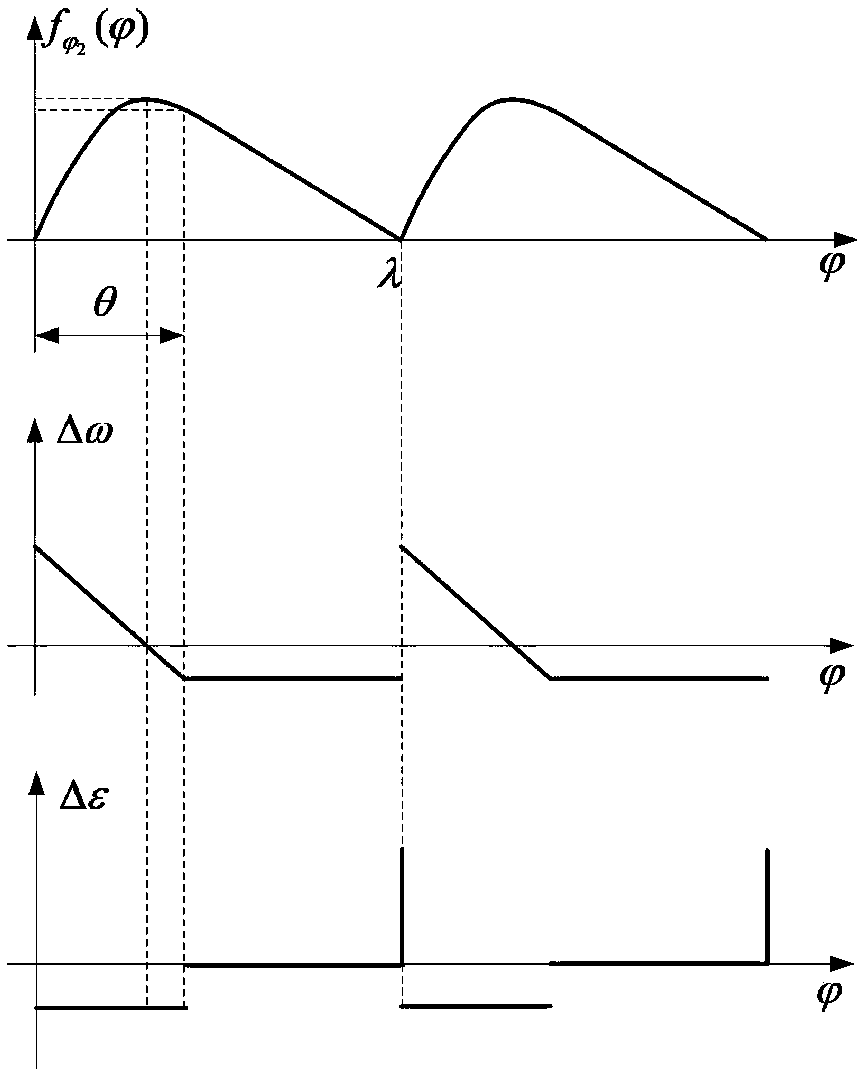

[0072] transmission error Angular velocity error Δω 2 , angular acceleration Δε 2 The corresponding error curve is as figure 2 As shown, at the point of engagement impact, the speed of the driven wheel jumps, theoretically producing infinite acceleration, but due to damping and elastic deformation of the contact point, the acceleration cannot be infinite, but a pulse; after that, the driven wheel gradually decelerates to involute meshing. Due to the base joint err...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com