Automatic feeding method and system for multiple varieties and small batch of PCBs

A PCB board, automatic feeding technology, applied in general control systems, control/regulation systems, comprehensive factory control, etc., can solve the ambiguity of product difficulty classification, high volatility, unfavorable historical data retrospective reference, large labor time investment, etc. problems, to achieve the effect of benefiting later order growth and customer expansion, improving production reputation and customer recognition, and saving material waste and time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0067] In order to fully understand the technical content of the present invention, the technical solutions of the present invention will be further introduced and illustrated below in conjunction with specific examples, but not limited thereto.

[0068] like Figure 1-12 In the specific embodiment shown, this embodiment provides an automatic feeding method for multi-variety and small-batch PCB boards, which can be used in the pre-feeding lean production process of multi-variety and small-batch printed circuit boards to eliminate the difference in manual feeding experience Improve the stability of feeding, improve production efficiency, improve accuracy, and promote automated lean production.

[0069] A kind of automatic feeding method of multi-variety and small-batch PCB board provided in this embodiment, the method comprises:

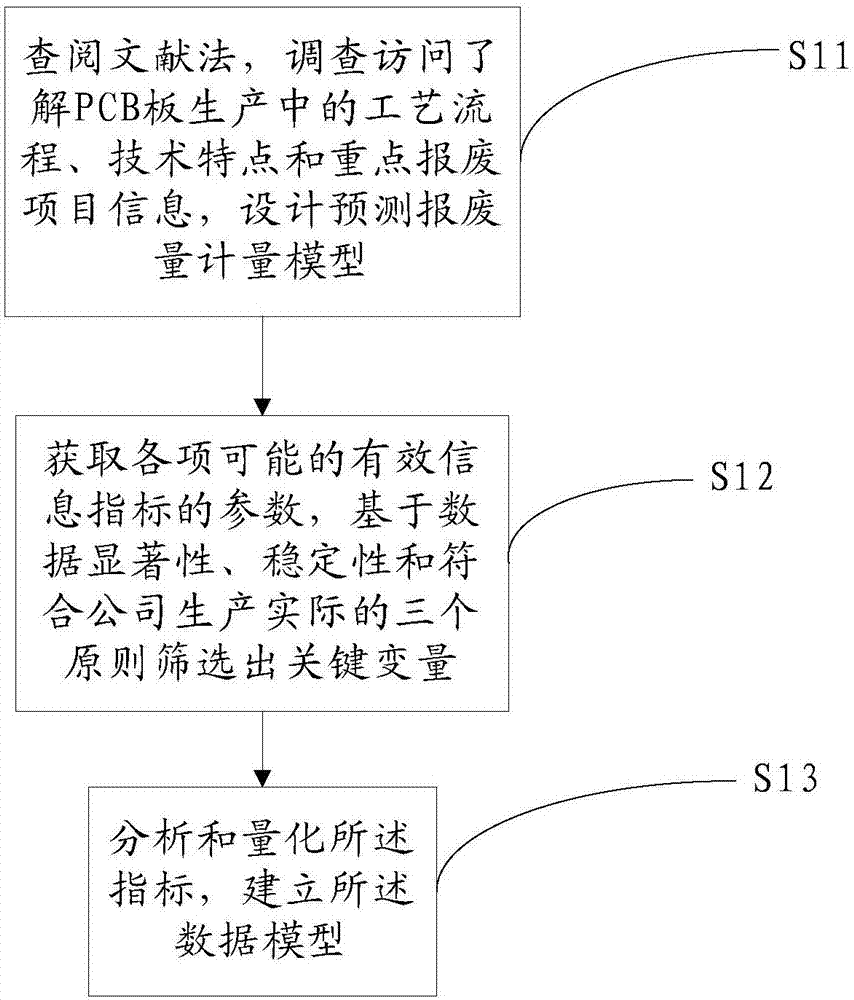

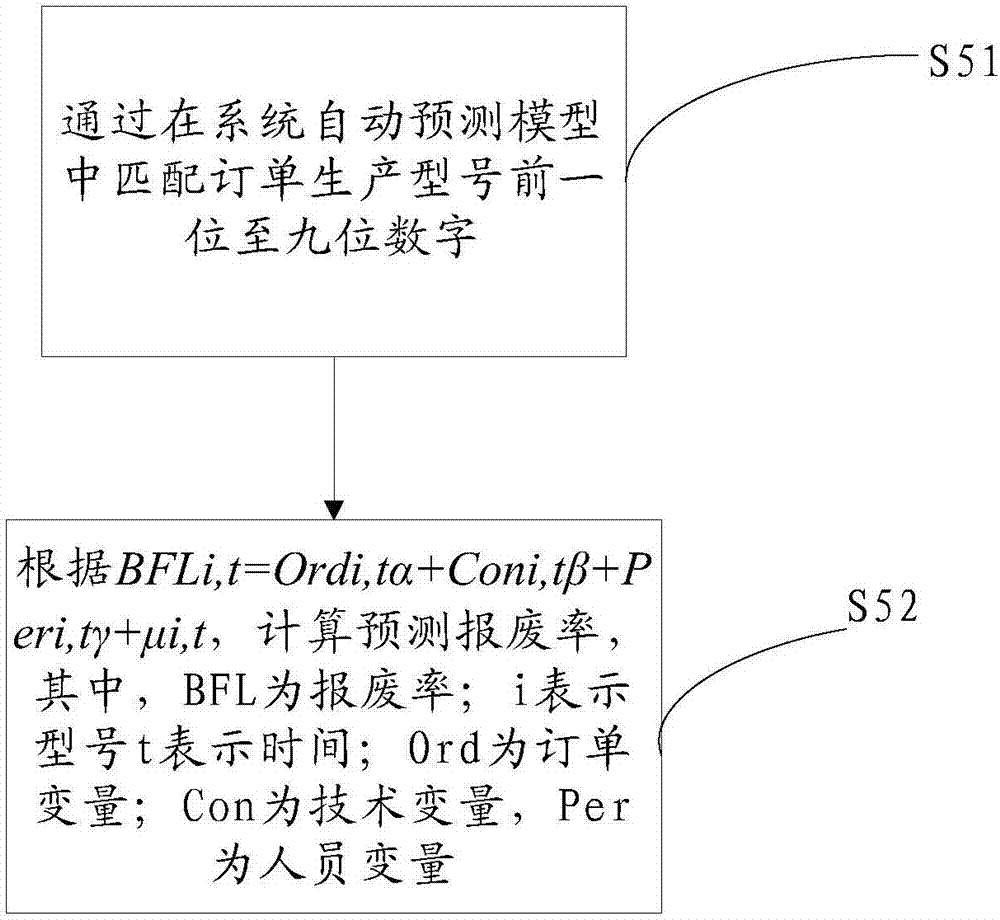

[0070] S1. Based on the big data of production material input and scrap data and product order parameter information, analyze and screen key variabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com