Method for calculating fracture toughness of shale based on scratch experiment

A fracture toughness and scratch test technology, applied in the direction of strength characteristics, test sample preparation, sampling, etc., can solve the problems of heavy workload and achieve the effects of weakening the discrete type, comprehensive experimental support, and low difficulty in sample preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The content, features and effects of the present invention will be further described in detail below with reference to the accompanying drawings and examples. The specific steps of the method for calculating shale fracture toughness in the scratch test are as follows:

[0021] Step 1. Select a certain underground shale core, use a rock cutter to cut a columnar core with a diameter of 106mm and a length of 250mm, and then fully dry the core at 60°C for use after completion;

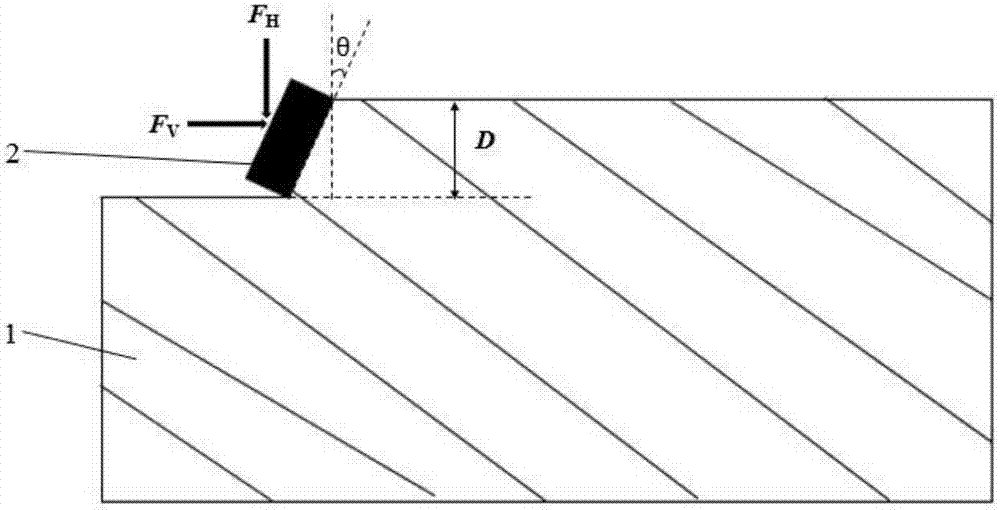

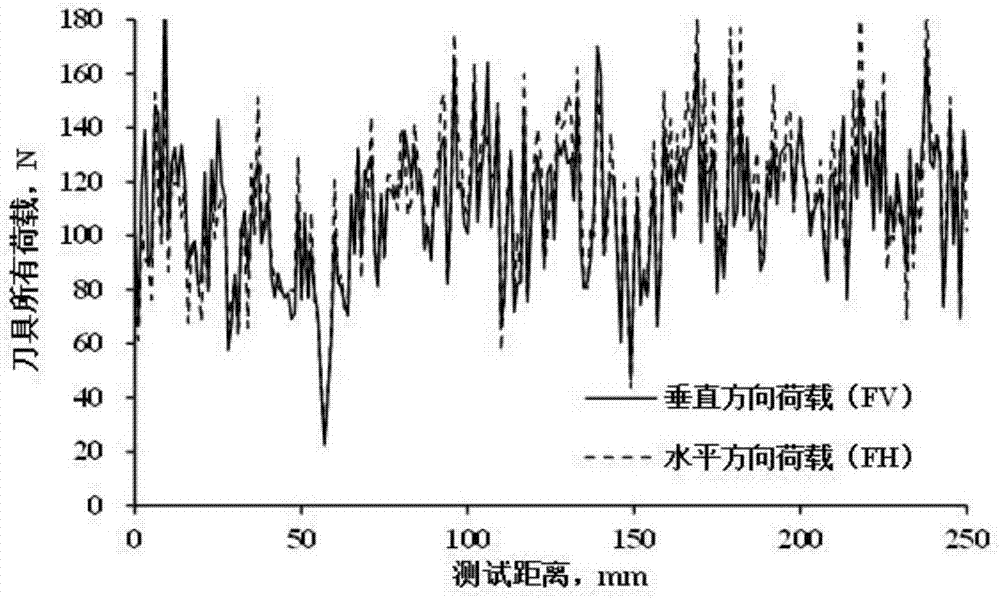

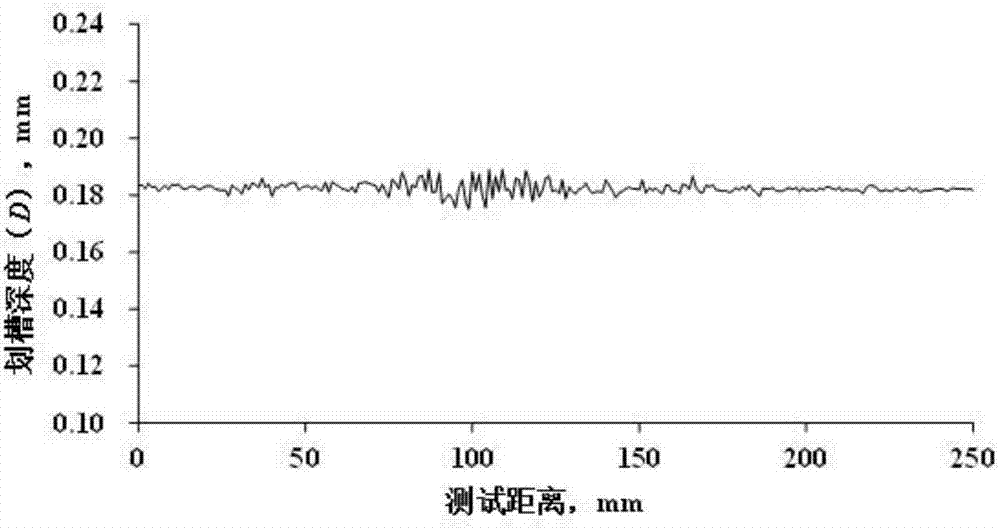

[0022] Step 2. Fix the prepared core on the TerraTek MP scratch tester, and place the core strictly horizontally along the long axis; the scratch test uses a parallelepiped alloy steel tool, and adjust the angle between the tool and the vertical to 15° , The tool width (W) is 5mm; adjust the up and down position of the tool to ensure that the groove depth of the tool on the upper end of the core is about 0.2mm; turn on the feed button and perform a scratch test along the long axis of the core cylinder. Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com