Drop hammer impact clamp with variable sample size, variable impact point and variable boundary conditions

A technology of boundary conditions and drop weight impact, which is applied in the field of drop weight impact fixtures, can solve problems such as the inability to achieve variable impact positions and variable boundary condition impacts, the inability to use different sizes of specimens for impact tests, and the inability to change the boundary conditions of impact, etc. Achieve the effects of enriching test types, reducing the difficulty of sample preparation, and reducing the number of samples

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

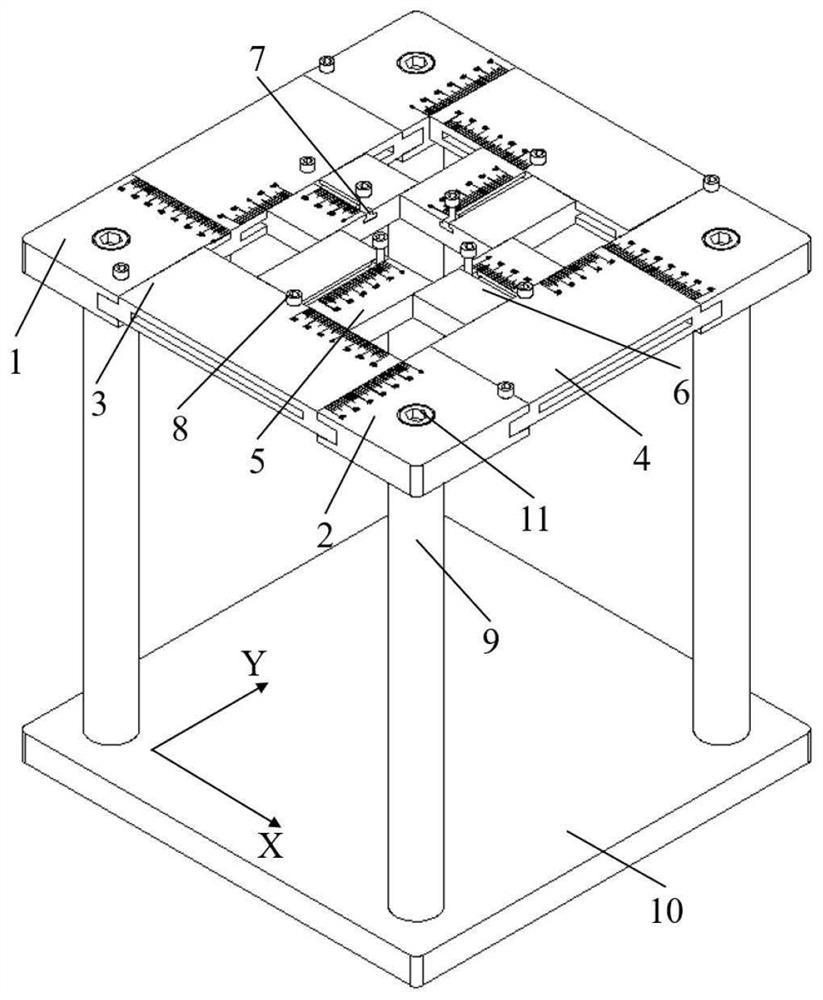

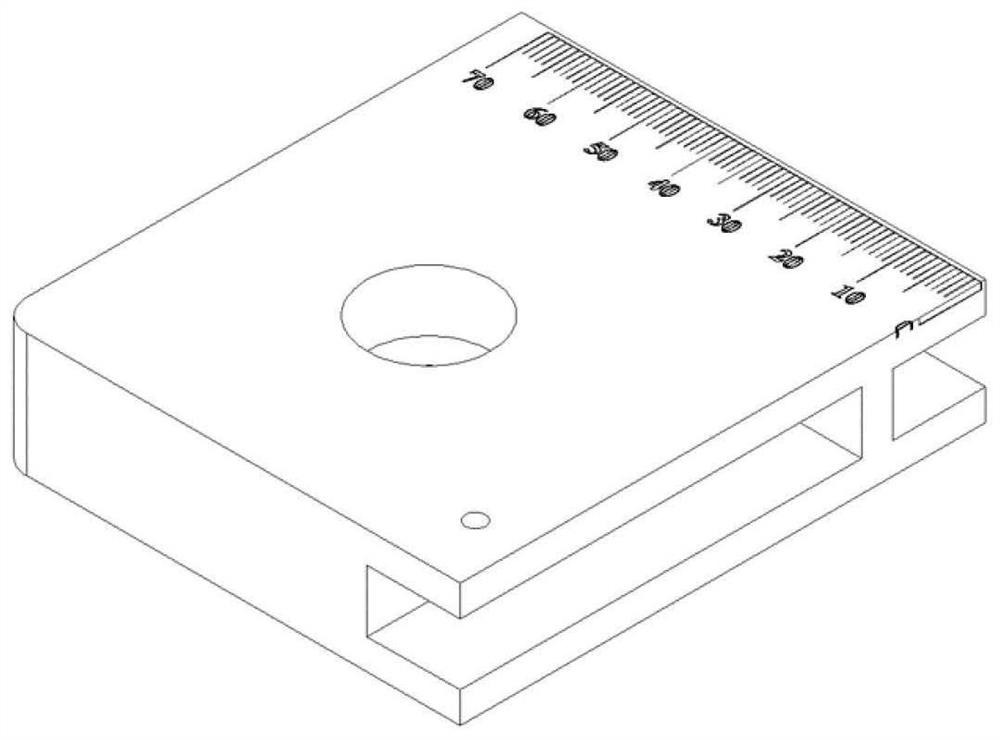

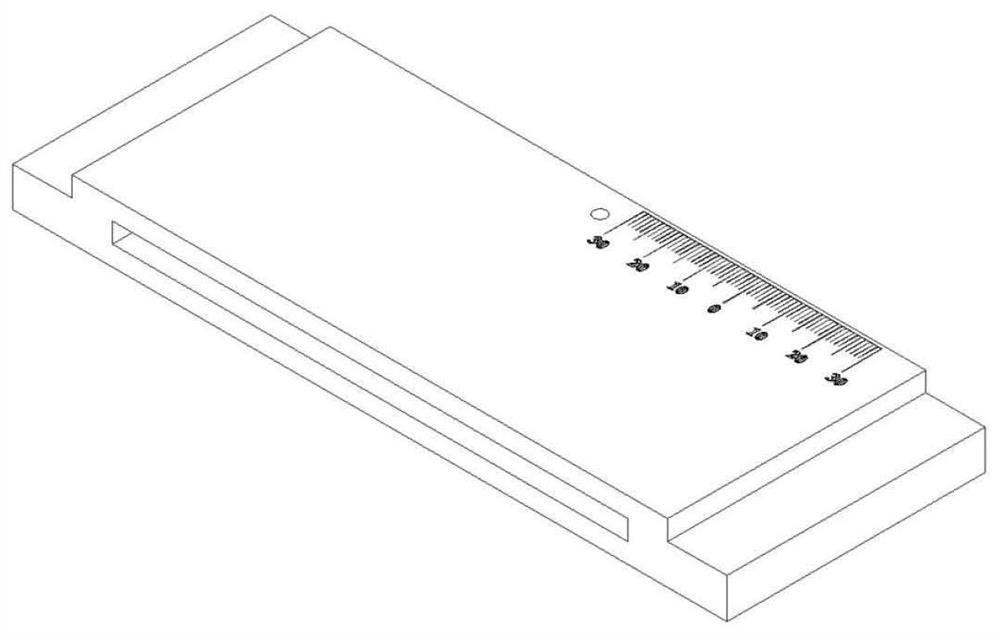

[0042] A drop hammer impact fixture with variable size, variable thickness, and variable impact point according to the present invention includes: the first upper base 1, on which there are 75mm×15mm×10mm guide rails, 65mm×15mm×10mm guide rails, 70mm scales, and M4 threaded holes and M10 threaded holes are used to provide support, guidance and positioning for the Y-direction position slider 3 and the X-direction position slider 4; the second upper seat 2 has a 75mm×15mm×10mm guide rail, a 65mm×15mm×10mm guide rail, 60mm scale, M4 threaded hole and M10 threaded hole, used to provide support, guidance and positioning for Y-direction position slider 3 and X-direction position slider 4; Y-direction position slider 3 has a 65mm×15mm×10mm slider Rail, 130mm×5mm×65mm guide rail, 30mm bidirectional scale and M4 threaded hole, used to cooperate with the first upper seat 1 and the second upper seat 2 to slide along the Y direction and provide support, guidance and positioning for the X-d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com