Compact camera module (CCM) test platform

A test platform and test tooling technology, applied in optical instrument testing, electronic circuit testing, machine/structural component testing, etc., can solve problems such as waste of human-machine resources, low UPH output value, etc., to avoid waiting and simplify operations Steps, the effect of improving the utilization of people and machines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Various embodiments of the present invention will be described below with reference to the accompanying drawings.

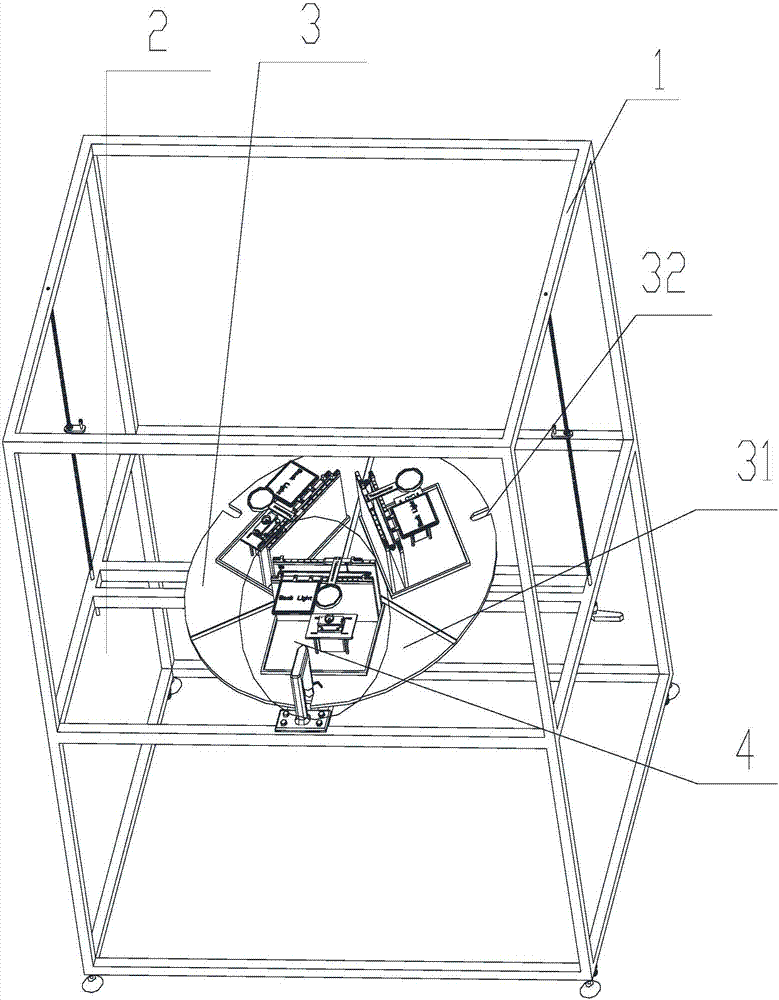

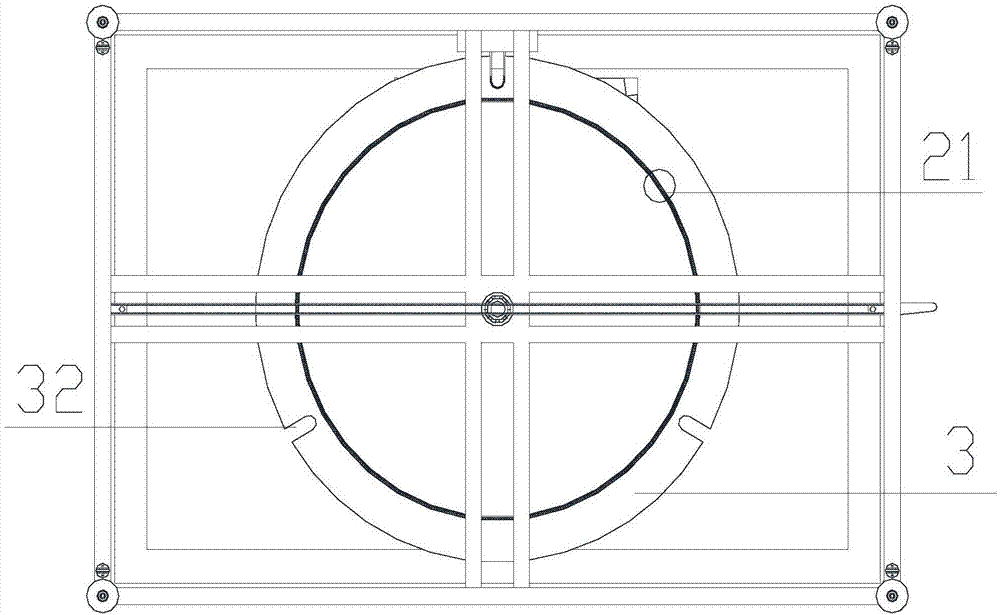

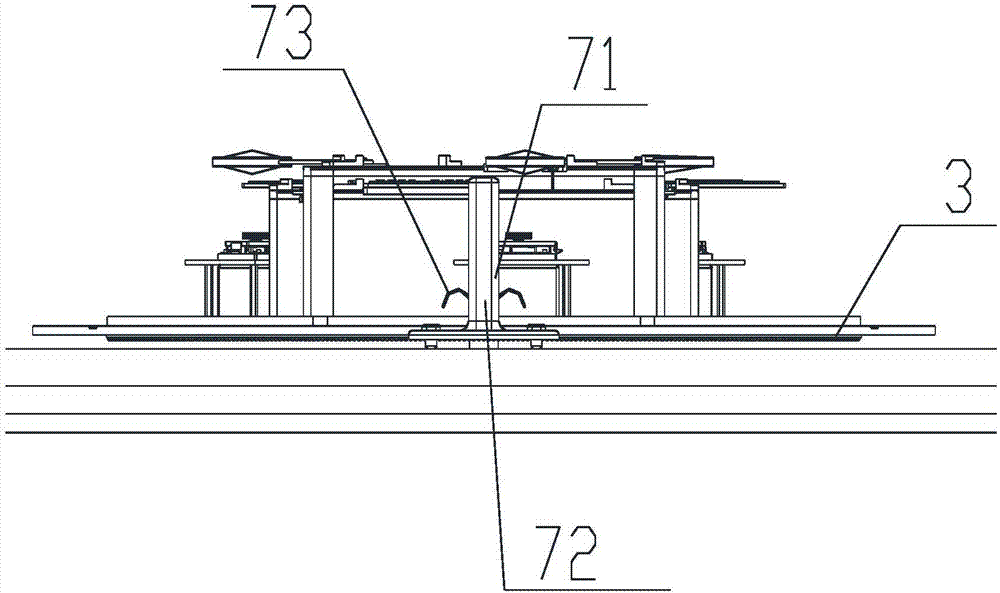

[0032] Aiming at the problems of waste of man-machine resources and low UPH output value in the aforementioned existing CCM testing machine, the present invention sets a circular rotating platform on the working platform, and sets at least two test fixtures on the circular rotating platform. The first slide rail and the second slide rail connected with the first transmission belt are arranged on the test fixture, and the teleconverter is arranged on the first slide rail, and the small light plate is arranged on the second slide rail, so that the teleconverter and the second slide rail The small light board can move horizontally and reset automatically through the first transmission belt, the first slide rail and the second slide rail, thereby simplifying the operation steps of the test personnel, and when a test tool is used for a certain test, other items ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com