Triple-frame dual-mass silicon micromachined gyroscope with direct frequency output

A frequency output, silicon micro-mechanical technology, used in gyroscope/steering sensing equipment, gyro effect for speed measurement, instruments, etc. Small quadrature error, achieving the effect of structural decoupling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings.

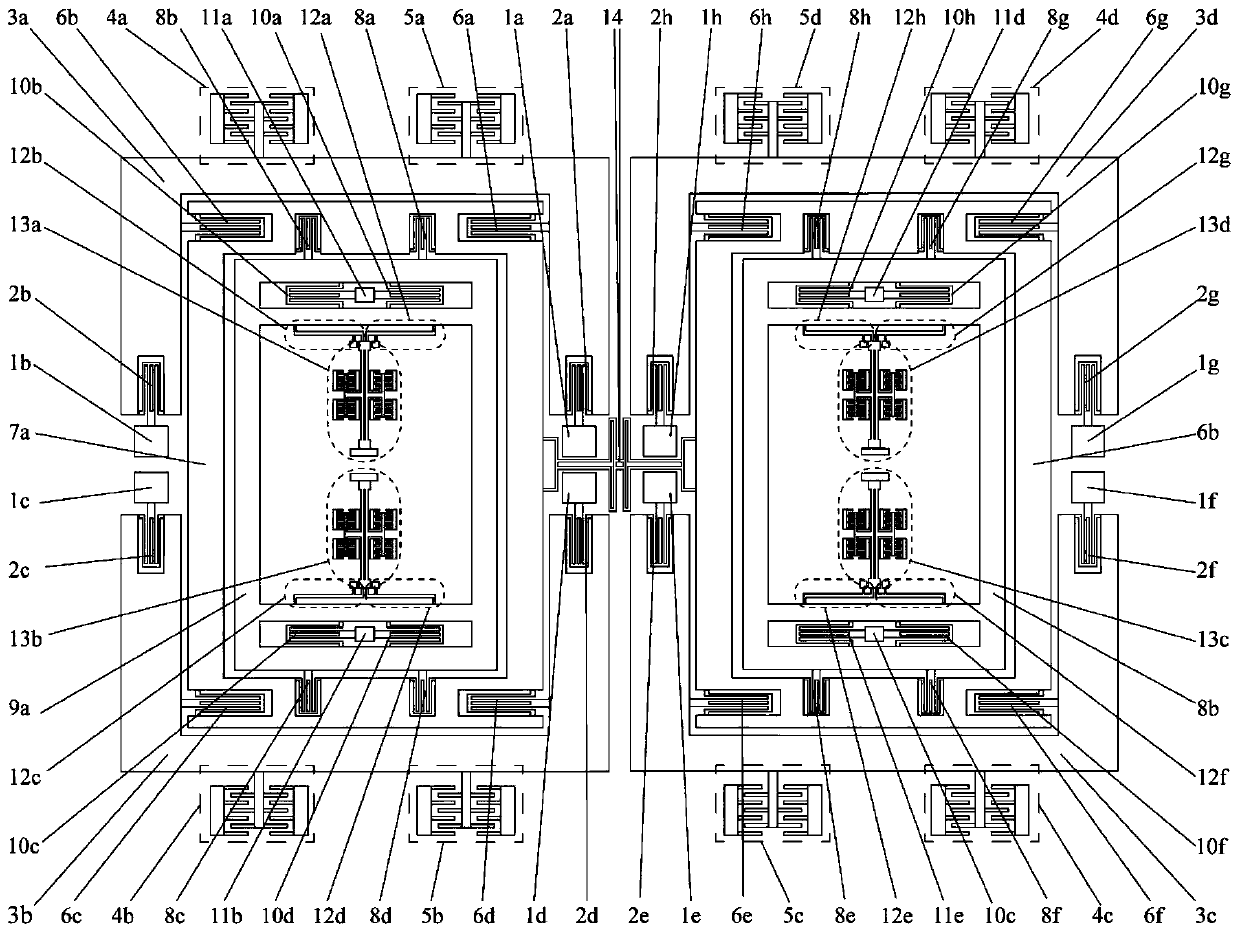

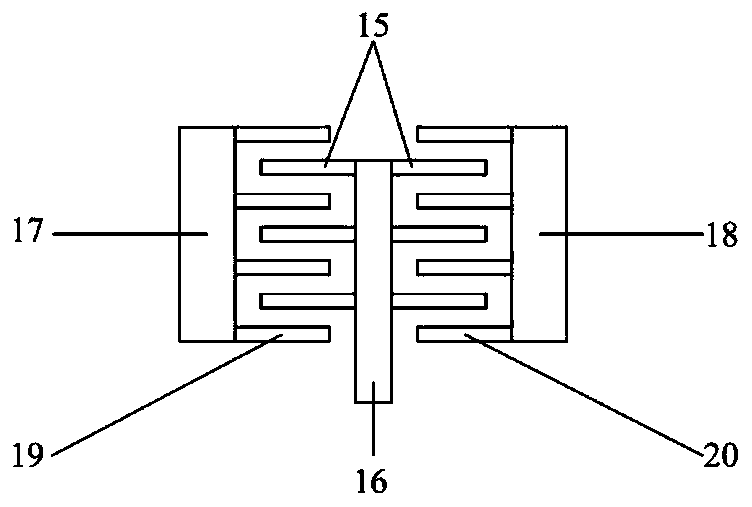

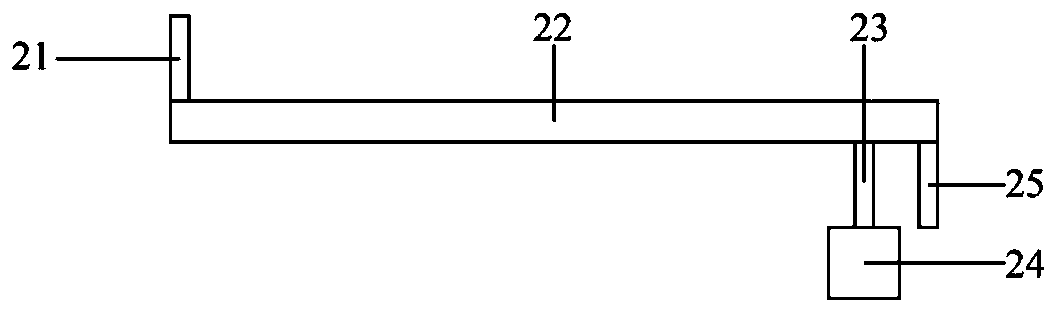

[0026] Such as figure 1 , figure 2 Shown, a kind of direct frequency output of the present invention's three-frame dual-mass silicon micromachined gyroscope includes a lower glass substrate, a lead layer, a bonding layer and an upper silicon structure layer, and metal is sputtered on the upper surface of the lower glass substrate As the lead layer, a bonding layer covering the lead layer and the lower glass substrate is provided on the lower glass substrate, and the upper silicon structural layer is suspended on the lower glass substrate through the bonding layer; the upper silicon structural layer includes two upper silicon The micromechanical substructure and the coupling connection beam, the two upper silicon micromechanical substructures are symmetrical about the vertical central axis of the structure.

[0027] Such as figure 1 As shown, the first upper silicon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com