Automatic detection system and method for numerical control electrical discharge machining equipment

A processing equipment, automatic detection technology, applied in the field of detection, can solve problems such as difficulty, impact on output, low efficiency, etc., to reduce rework waste, reduce labor intensity, and improve detection efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below with reference to the accompanying drawings and examples. It should be noted that, in the case of no conflict, the following embodiments and features in the embodiments can be combined with each other.

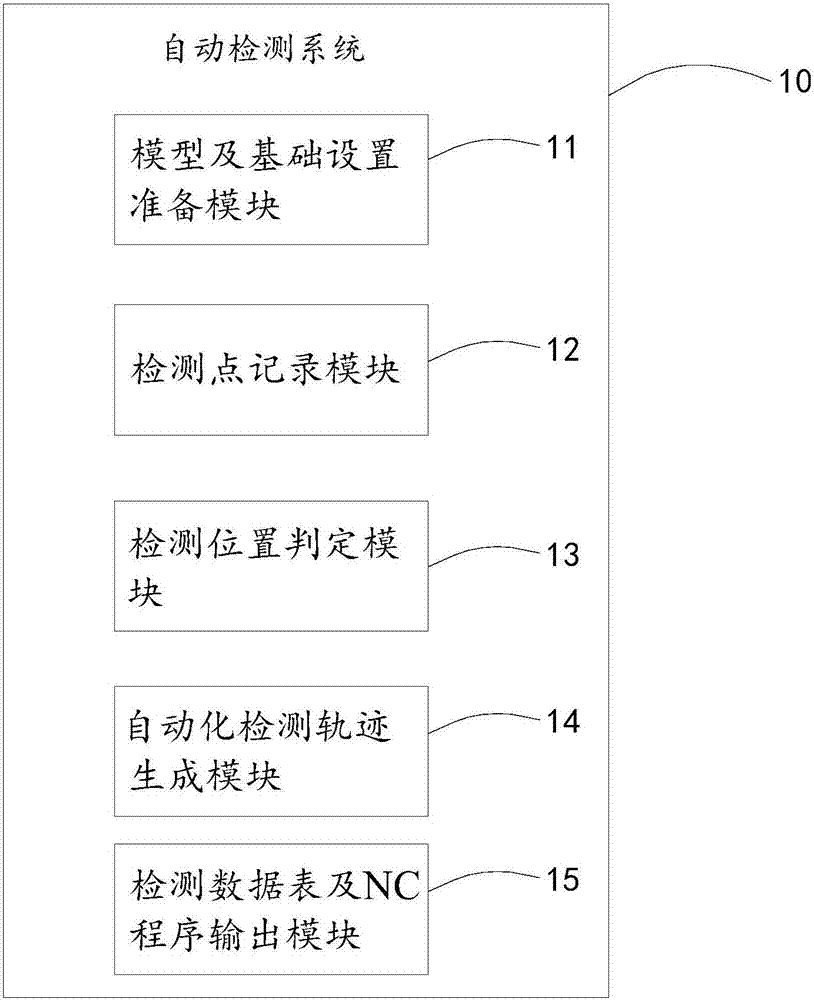

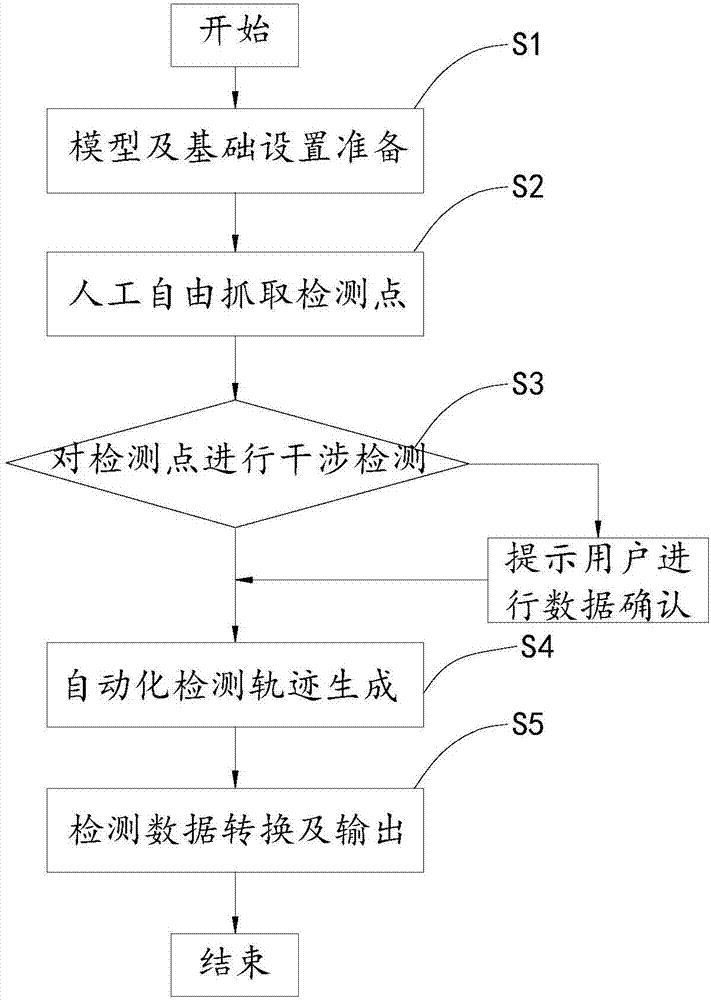

[0029] see figure 1 As shown, it is a functional block diagram of an automatic detection system for numerical control electric discharge machining equipment in one embodiment of the present invention. In this embodiment, the automatic detection system 10 of CNC EDM equipment includes a model and basic setting preparation module 11, a detection position recording module 12, a detection position determination module 13, an automatic detection trajectory generation module 14, and a detection data table and NC code output module 15. The module refers to a program segment capable of completing a specific function.

[0030] The model and basic setting preparation module 11 is used to obtain the three-dimensional model...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com