Double-layer permanent magnet type axial eddy current recoil and counter-recoil device

A permanent magnet and eddy current technology, applied in magnetic springs, springs/shock absorbers, mechanical equipment, etc., can solve the problems of small damping coefficient and low work efficiency, and achieve improved damping coefficient, less space occupation, and radial volume. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to illustrate the technical scheme and technical purpose of the present invention, the present invention will be further introduced below in conjunction with the accompanying drawings and specific embodiments.

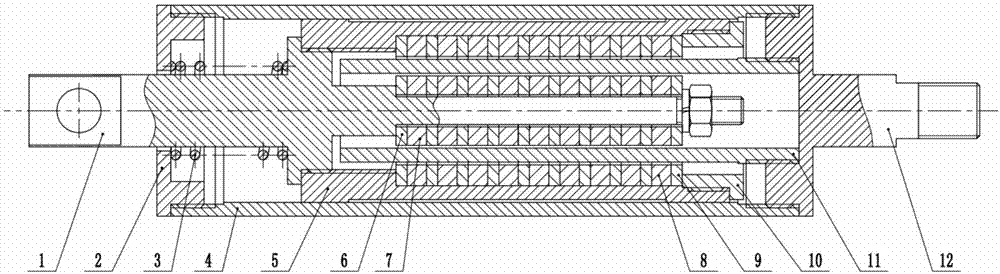

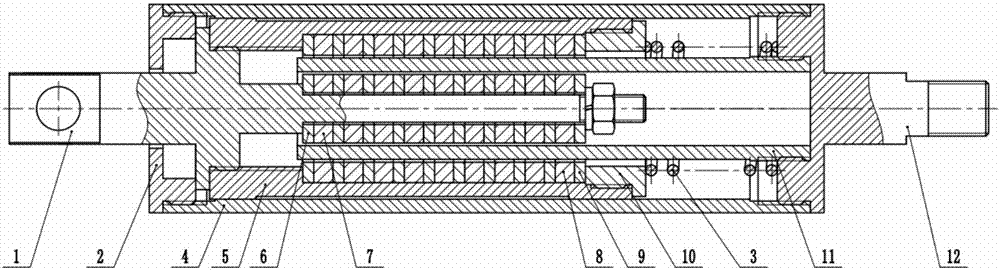

[0023] A double-layer permanent magnet type axial eddy current restraining and re-advancing device of the present invention includes a support mechanism, an eddy current damping mechanism and a re-advancing mechanism; Layer permanent magnet 9 produces relative movement;

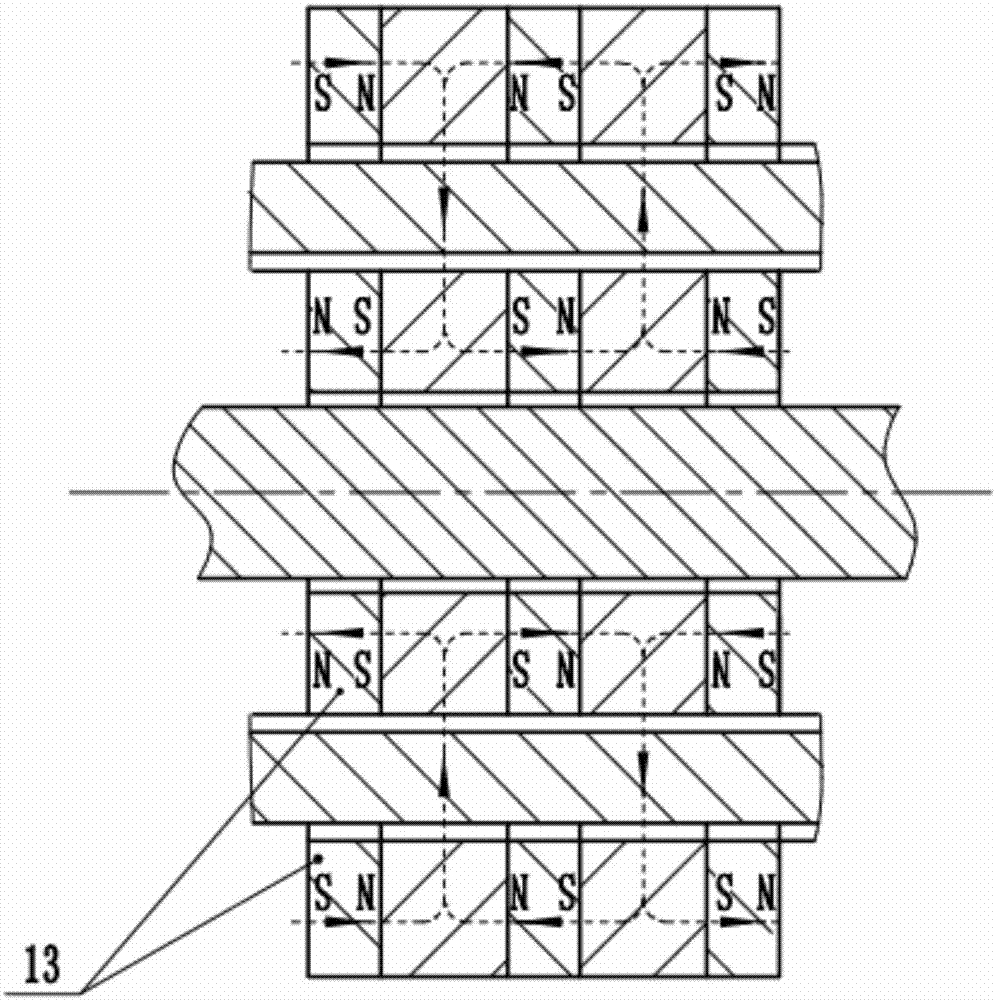

[0024] The eddy current damping mechanism includes an inner permanent magnet 6, an outer permanent magnet 9, and an outer magnetic block 8; The inner diameter of the inner permanent magnet 6 is greater than the outer diameter of the inner permanent magnet 6, and the inner permanent magnet 6 and the outer permanent magnet 9 are coaxially installed; 11 is located between the inner permanent magnet 6 and the outer permanent magnet 9, and the circular tube 11 generates relative motion wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com