Reciprocating hydraulic driving device

A driving device, reciprocating technology, applied in the direction of fluid pressure actuating device, etc., can solve the problems of complex overall system, inconvenient movement, high failure rate, etc., and achieve the effect of high integration, convenient movement, and low failure rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

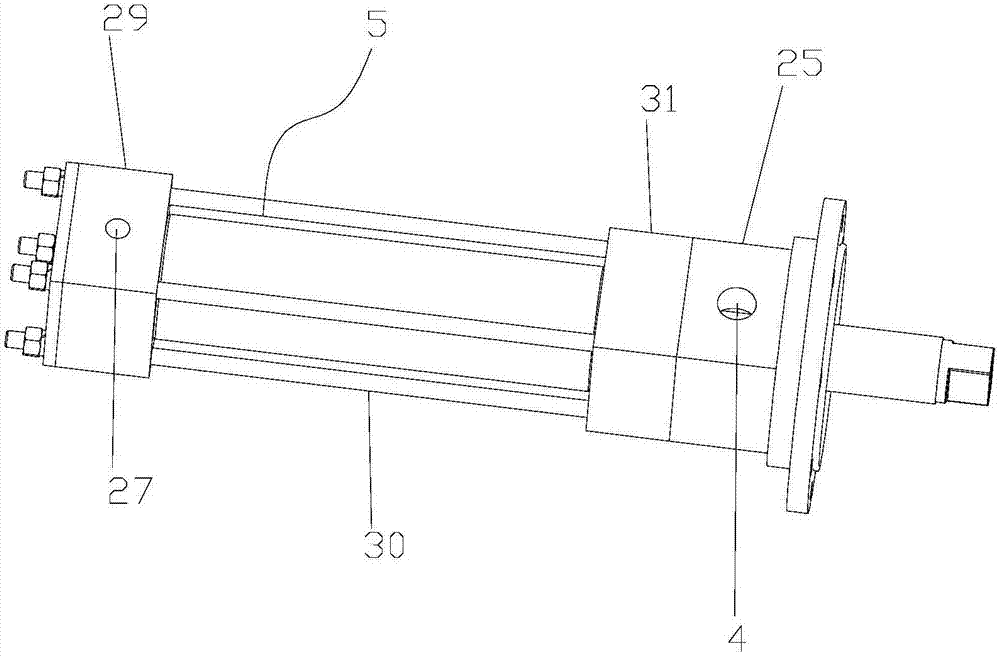

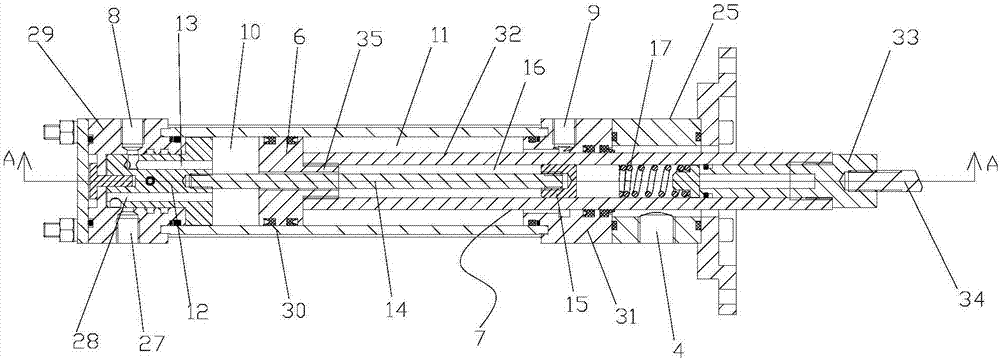

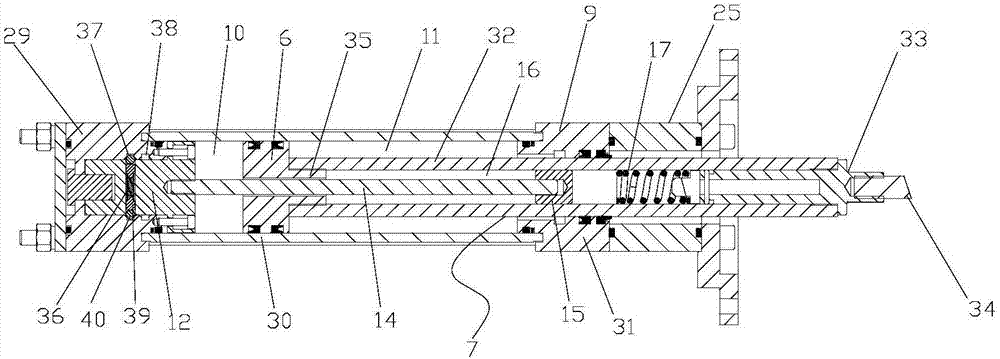

[0020] figure 1 It is a schematic diagram of the appearance structure of the present invention, figure 2 It is a sectional view of the overall structure of the present invention, image 3 for figure 2 Structural cross-sectional view in the direction of A-A, Figure 4 It is the overall assembly diagram used in the grouting pump of the present invention, as shown in the figure: the reciprocating hydraulic drive device of this embodiment includes a hydraulic cylinder block 5 and can be driven by hydraulic oil to reciprocate axially along the inner wall of the hydraulic cylinder block 5 The hydraulic piston 6 set for movement also includes a piston rod 6 that is located in the hydraulic cylinder body and connected to the hydraulic piston 6, and the other end extends out of the hydraulic cylinder body. The piston rod 6 can be slid in the axial direction and form a circumferential seal. Cooperate with the hydraulic cylinder block 5, the hydraulic cylinder block is provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com