Electric clippers

A technology of electric scissors and cutting blades, applied in the field of disaster relief equipment, can solve the problems of inconvenient use, heavy weight, and low work efficiency for users, and achieve the effects of being easy to carry over long distances, reducing volume, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

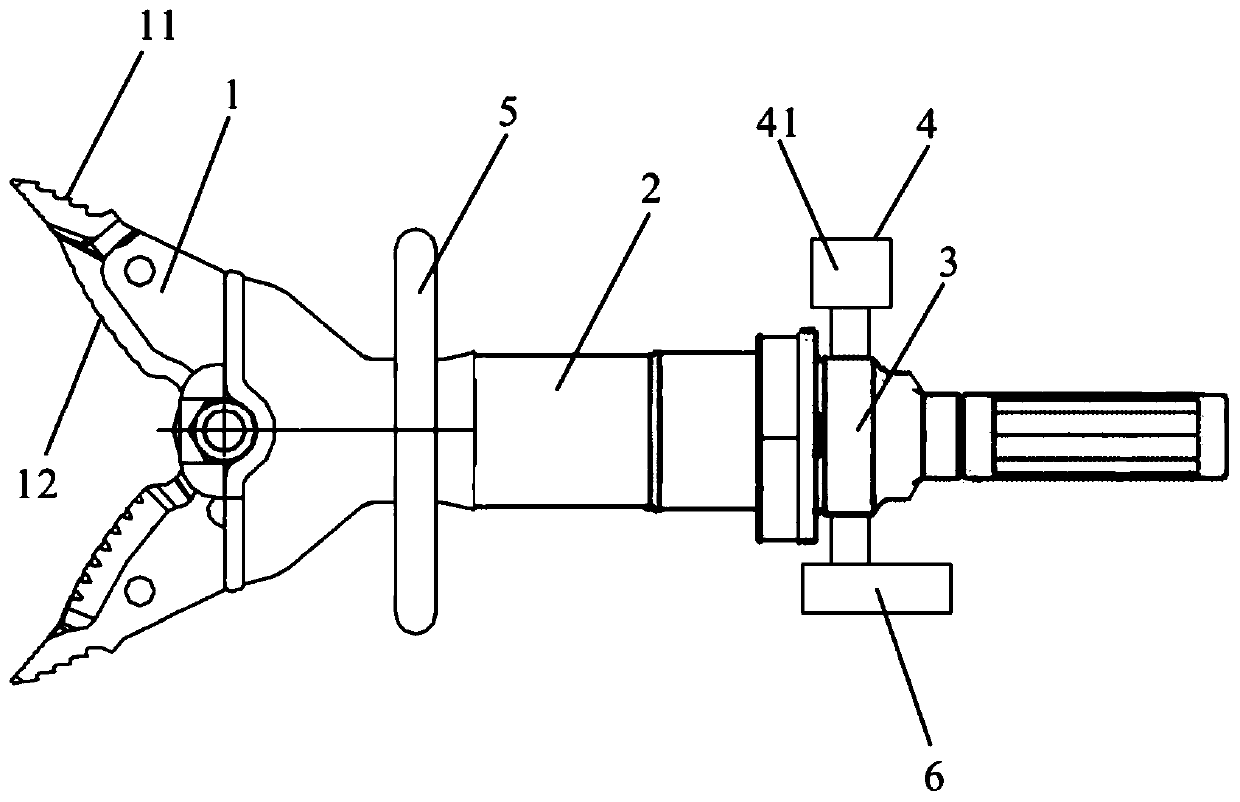

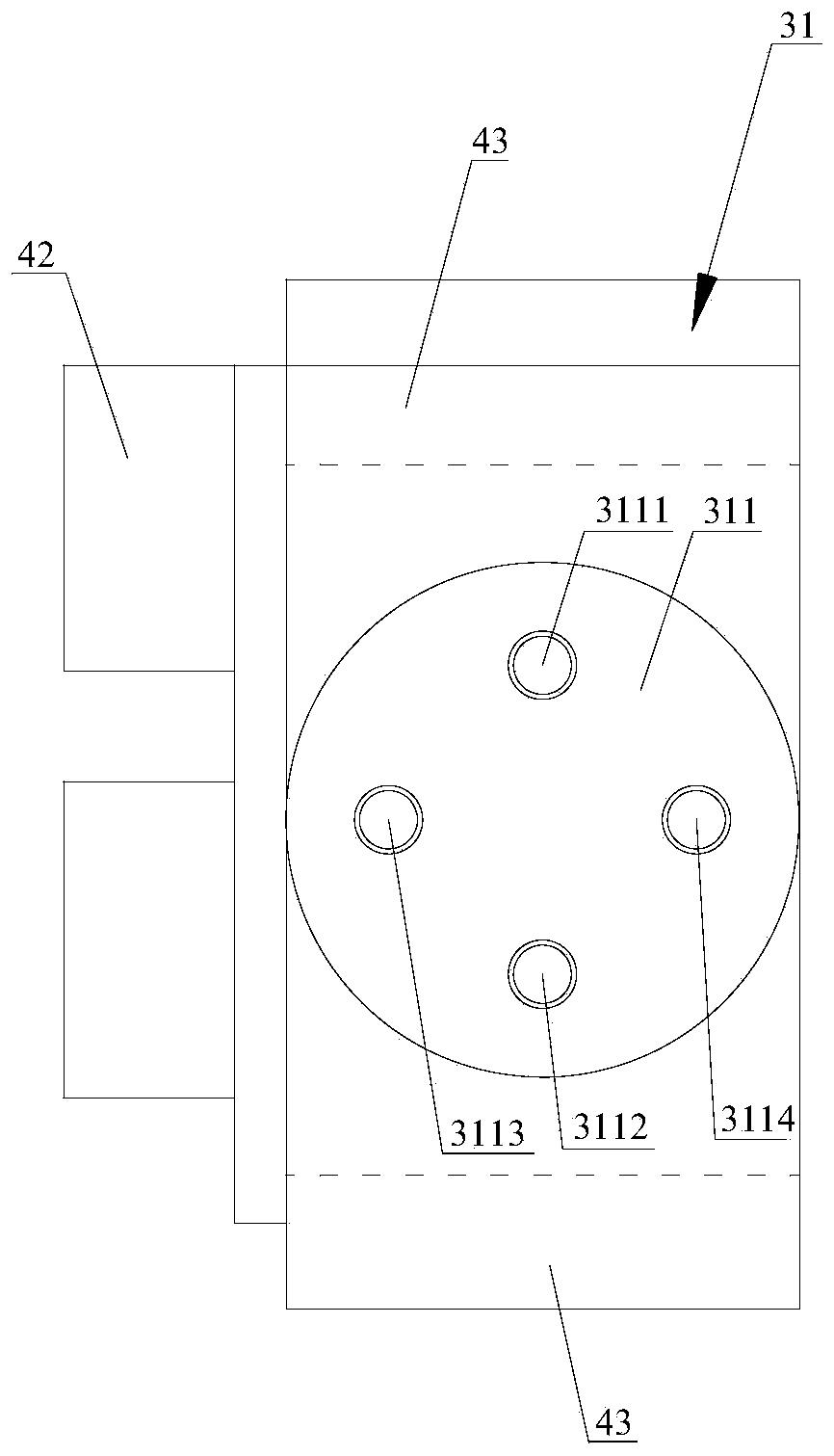

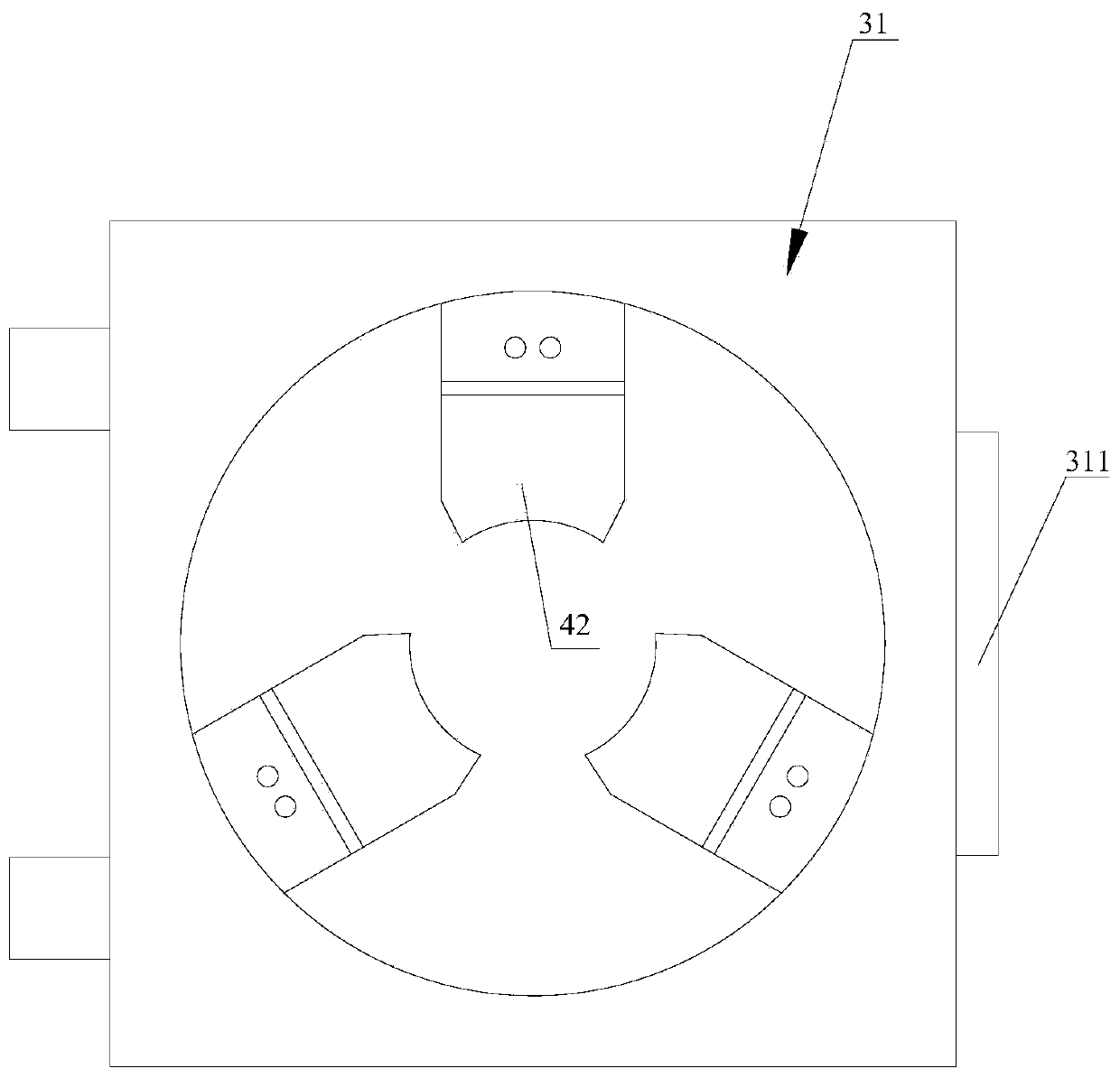

[0042] Such as figure 1 As shown, the electric shear expander provided in this embodiment includes a shear expander working head 1 , a hydraulic drive assembly 2 , a reversing assembly 3 and an oil inlet assembly 4 . The shearing and expanding working head 1 includes two intersecting and movably connected shearing and expanding parts, each of which has a cutting edge 11 on the inside and an expanding part 12 on the outside. The hydraulic drive assembly 2 is connected to the shear expansion working head 1 to drive the two shear expansion parts to open or close. The reversing assembly 3 is connected with the hydraulic drive assembly 2 and provides the hydraulic drive assembly 2 with two oil circulations in opposite directions. The oil inlet assembly 4 is connected with the reversing assembly 3 .

[0043] The electric shear expander provided by the present invention integrates shearing and expansion, specifically:

[0044]In the cutting state, the hydraulic drive assembly 2 dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com