Double degree of freedom hydraulic cylinder

A degree of freedom, hydraulic cylinder technology, applied in the field of hydraulic cylinders, can solve the problem of incomplete removal of pollutants on the surface of the guardrail, and achieve the effect of improving the cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

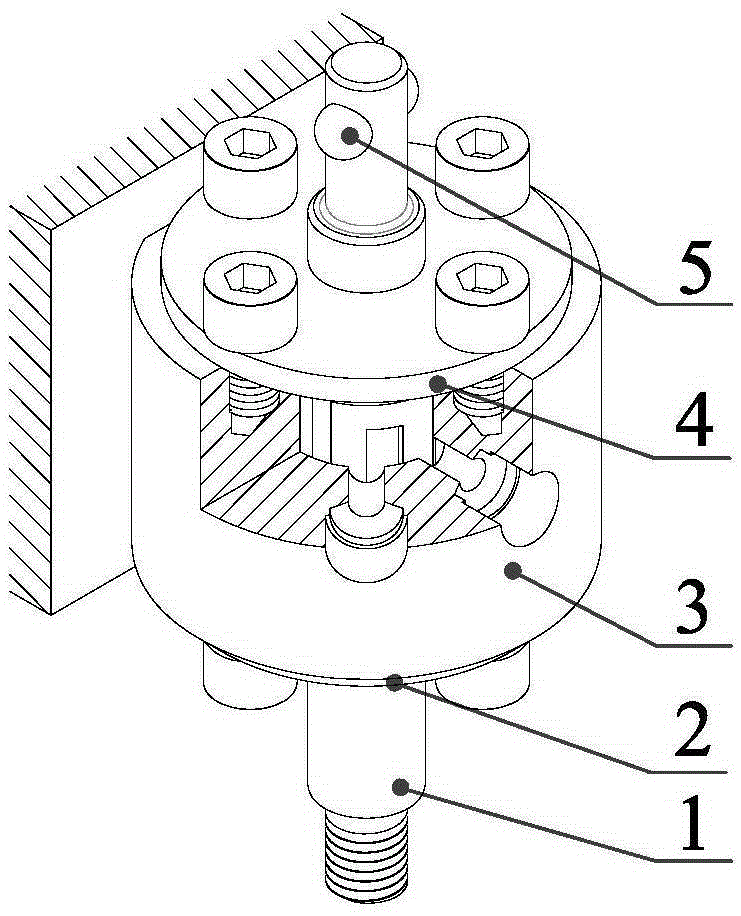

[0022] The present invention will be further described below in conjunction with the accompanying drawings.

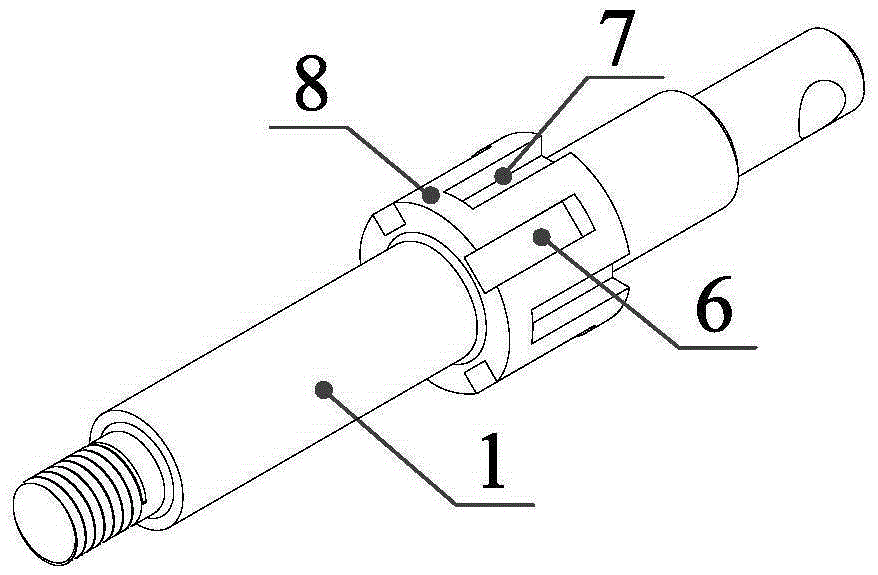

[0023] The dual-degree-of-freedom hydraulic cylinder includes: a piston rod, a cylinder body, and an end cover; it is characterized in that: the piston rod is connected to a piston, and the piston rod is connected to a hydraulic motor through a shaft sleeve, and the shaft sleeve does not restrict the piston Axial sliding of the rod, one end of the coupling sleeve is connected to the drive shaft of the hydraulic motor through a key, and the other end of the coupling sleeve is connected to the piston rod through a steel ball; the other end of the piston rod is connected to the load;

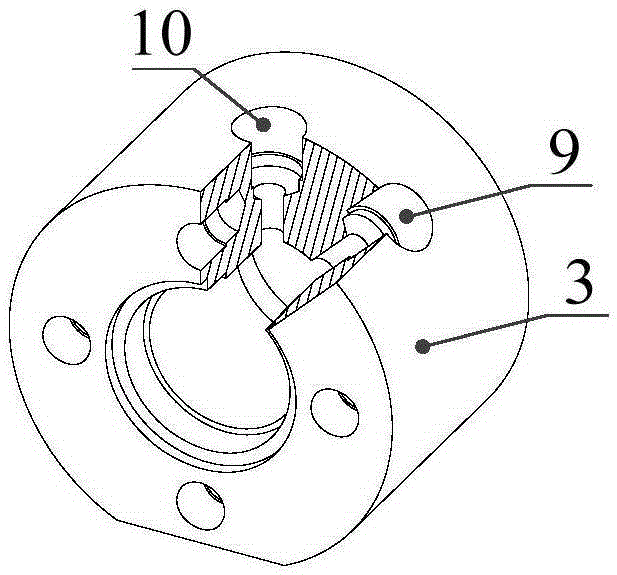

[0024] The side of the piston is evenly distributed with two sets of opposite grooves, the two sets of grooves have the same geometric shape, are spaced apart from each other, and are all parallel to the axis line of the piston rod; the first set The grooves only extend to one end face of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com