Preparation method for integrated thermal insulating outer wall of precast outer wall panel facing thermal insulation

A technology for insulating exterior walls and exterior wall panels, applied in ceramic molding machines, manufacturing tools, buildings, etc., can solve the problems of aging, loss of heat preservation effect, separation of heat preservation layer and protective layer, etc., so as to prolong the service life and shorten the construction period. , Improve the effect of thermal insulation quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The solution provided by the present invention for achieving the purpose of the invention is: a preparation method of a prefabricated external wall panel with an integrated thermal insulation and thermal insulation, comprising the following steps:

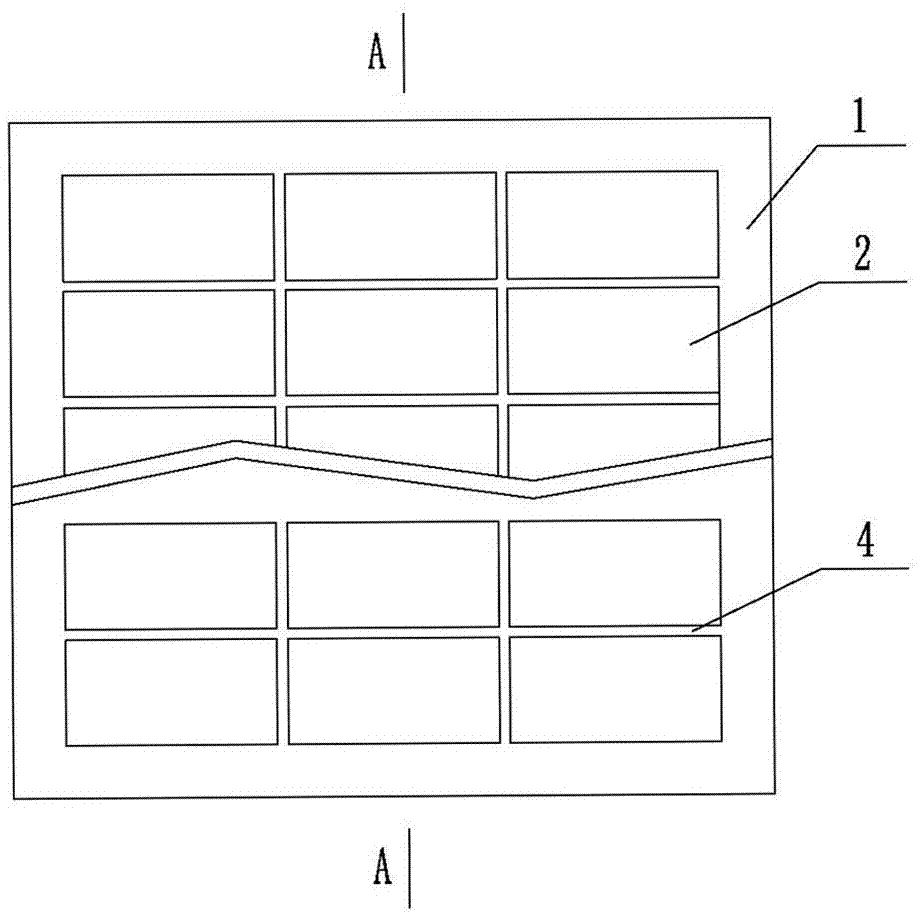

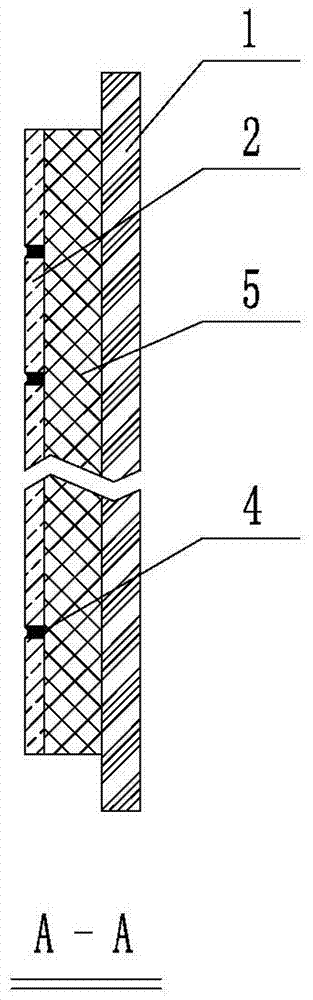

[0018] ① Take exterior wall panel 1 and exterior wall decorative panel 2 for spare;

[0019] ② Spray polyurethane infiltration transition layer on the outer surface of the exterior wall panel 1 and the inner surface of the exterior wall panel 2 to increase the adhesion of PU (polyurethane) liquid to the wall and board surface, which is a very important technical measure.

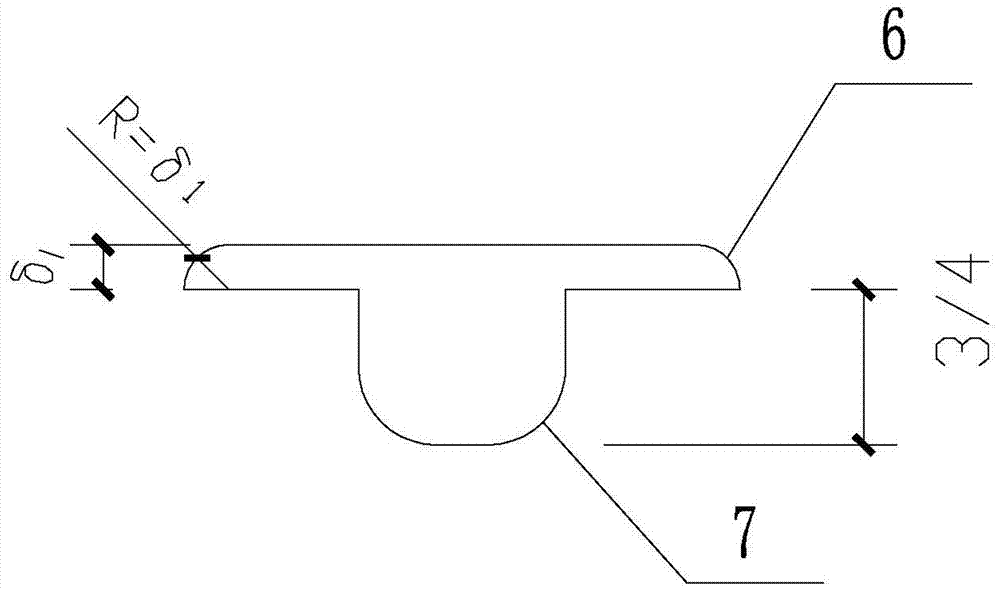

[0020] ③Paste at least four thickness control panels 3 on the inner surface of the exterior wall decorative panel 2. The thickness control panels 3 are rectangularly distributed on the exterior wall decorative panel 2, and the thickness control panels 3 are made of polyurethane material;

[0021] ④ Arrange multiple exterior wall panels 2 on the exterior wall panel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com