Full-automatic and efficient cleaned aluminum electrolysis cell

An aluminum electrolytic cell and fully automatic technology, which is applied in the field of aluminum electrolysis system, can solve the problems of shortening the pole changing time and achieve the effects of shortening the pole changing time, fast unmanned operation, and solving the uneven distribution of alumina concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

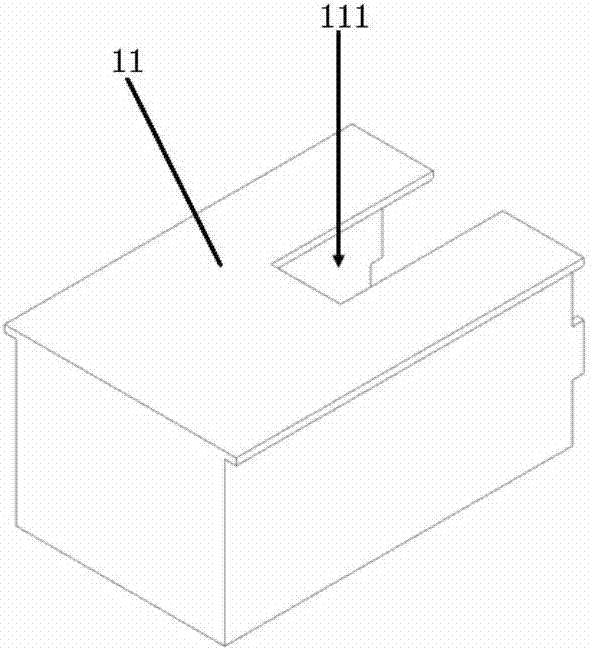

[0067] see Figure 1 to Figure 8 The controllable aluminum electrolytic cell anode covering sealing system in the illustration is a preferred solution arranged on the aluminum electrolytic cell of this embodiment, including a support frame 12 and several anode coating units 11 (in order to show the inside of the support frame structure, only represents one of the anode cladding units), wherein, the support frame 12 is a frame structure formed by welding several stainless steel rods and is installed above the aluminum electrolytic cell, and the side of the support frame 12 is connected with the groove of the aluminum-aluminum electrolytic cell The sides of the shell are sealed and fixed by side baffles. The top of the support frame 12 is welded by several parallel distributed stainless steel rods. The anode carbon blocks 8 are distributed between the gaps at the top of the support frame 12. The connected anode guide rods 81 Protruding from the gap between the supporting frame 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com