Method for preparing directionally-arranged SIC nanowire reinforced aluminum matrix composite material based on semi-solid extrusion

A technology of semi-solid extrusion and reinforcement of aluminum matrix, which is applied in the field of preparing oriented SiC nanowire reinforced aluminum matrix composite material based on semi-solid extrusion, can solve problems such as damage of SiC nanowire, and achieve excellent performance of composite material and process method. Simple, high-performance results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0022] Specific implementation mode 1: A method for preparing aligned SiC nanowire-reinforced aluminum-based composite materials based on semi-solid extrusion in this embodiment is carried out according to the following steps:

[0023] 1. Preparation of non-oriented SiC nanowire-reinforced aluminum matrix composites:

[0024] The non-oriented SiC nanowire-reinforced aluminum-based composite material is prepared by a solid-state method or a liquid-state method; the volume fraction of SiC nanowires in the non-oriented SiC nanowire-reinforced aluminum-based composite material is 5.0% to 35%, and the non-oriented SiC nanowire-reinforced aluminum matrix composite material is 5.0% to 35%. The volume fraction of aluminum-containing metal in the wire-reinforced aluminum matrix composite material is 65% to 95%; wherein the aluminum-containing metal is pure aluminum or aluminum alloy;

[0025] 2. Preheating of non-oriented SiC nanowire reinforced aluminum matrix composites and hot extru...

specific Embodiment approach 2

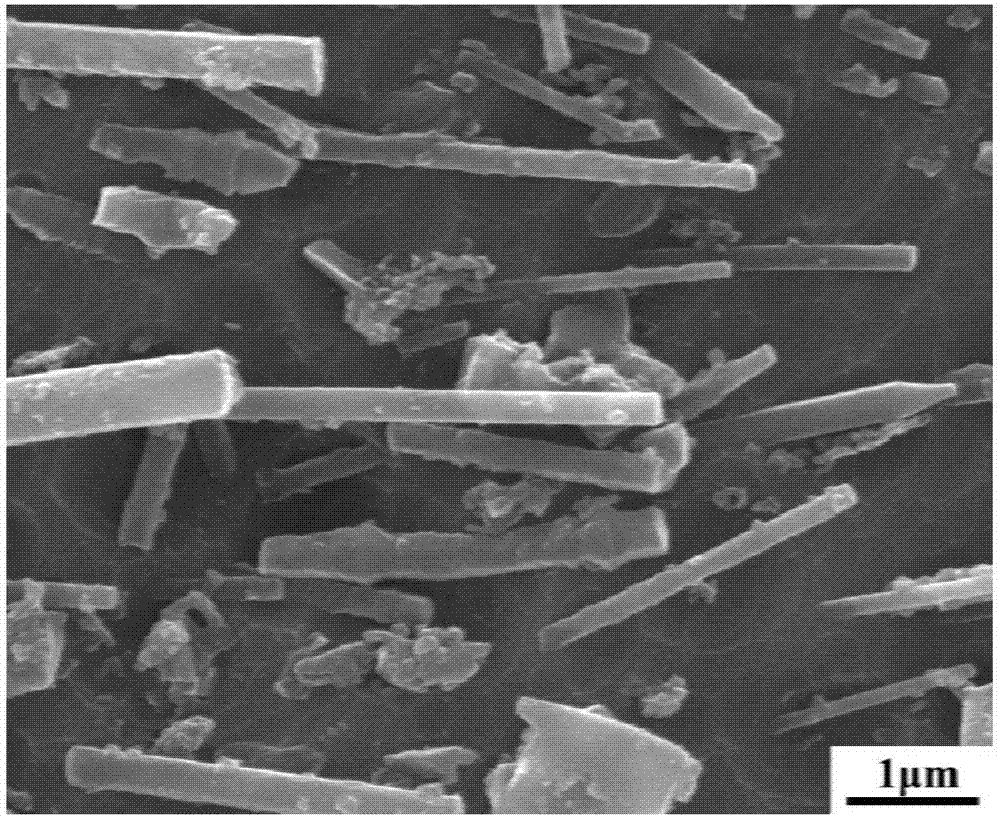

[0030] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that the SiC nanowires in step 1 have a purity greater than 85%, an average diameter of 5 nm to 250 nm, and a length of 5 μm to 100 μm; the SiC nanowires are Any combination of one or more of 3C, 2H, 4H and 6H. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0031] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the aluminum alloy described in Step 1 is Al-Si alloy, Al-Cu alloy, Al-Mg alloy, Al-Si-Cu alloy , Al-Si-Mg alloy, Al-Cu-Mg alloy, Al-Zn-Cu alloy, Al-Zn-Mg-Cu alloy, Al-Be alloy, Al-Li alloy and Al-Si-Cu-Mg alloy One or any combination of several of them. Others are the same as those in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com