Method for multi-production of simultaneous H2-CO-C2H2 and capturing of CO2 through circulating of calcium carrier

A H2-CO-C2H2, polygeneration technology, applied in the manufacture of combustible gas, calcium carbide immersed in water generator, petroleum industry and other directions, can solve the problems of wave production, adsorption efficiency decline, etc., to solve the problem of reduced efficiency, CO The effect of concentration reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the drawings and embodiments.

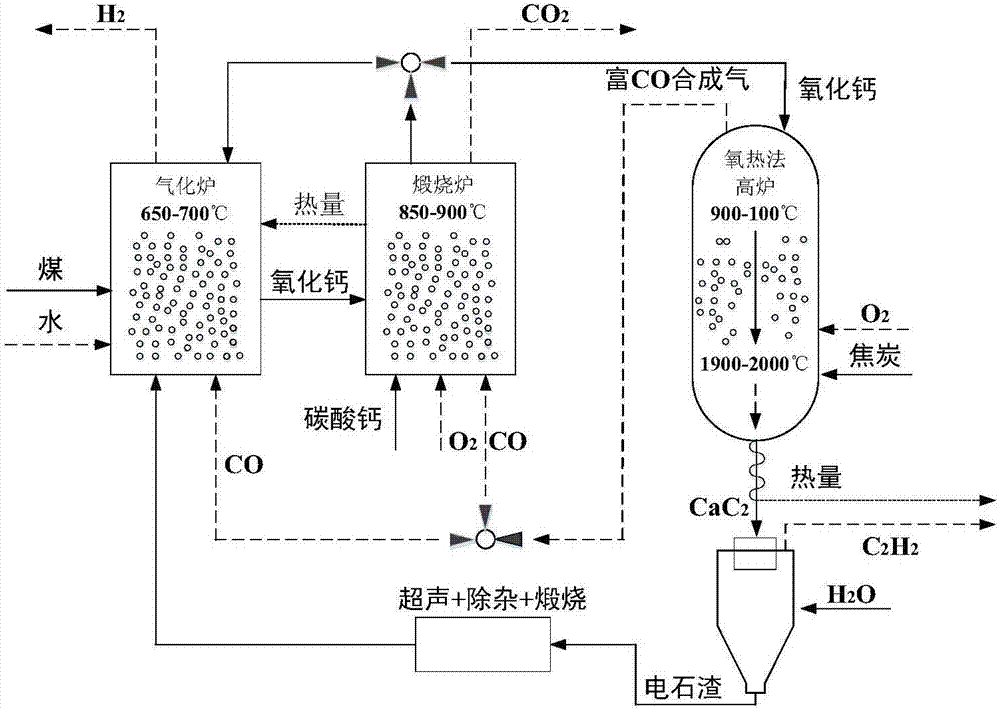

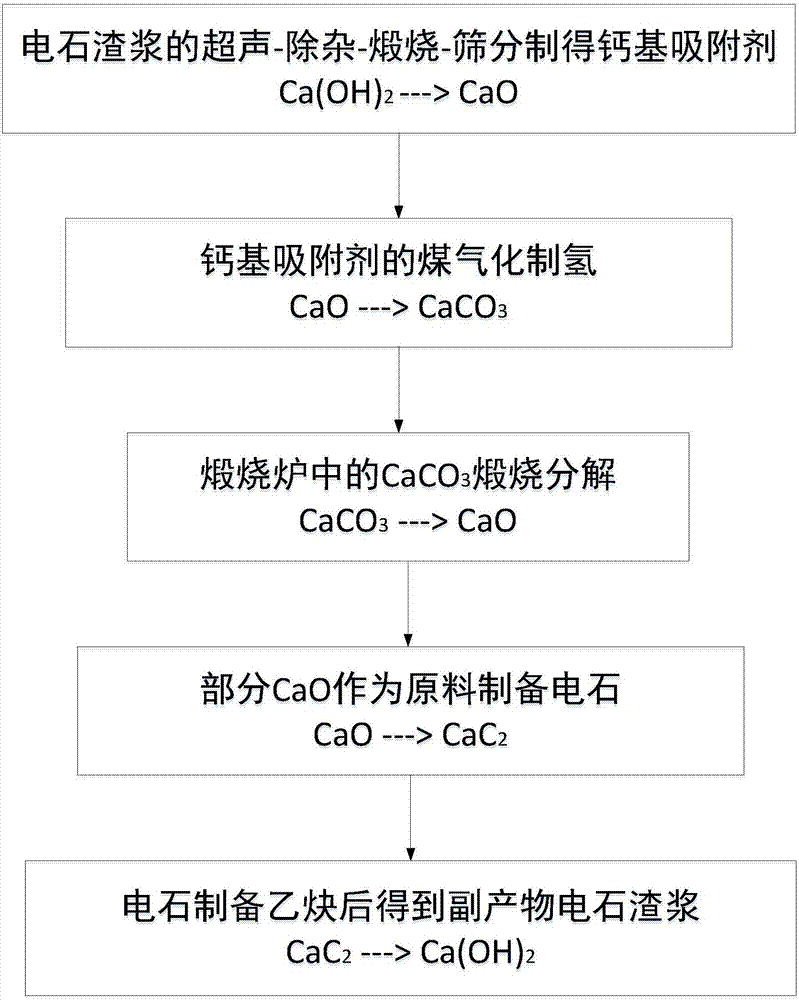

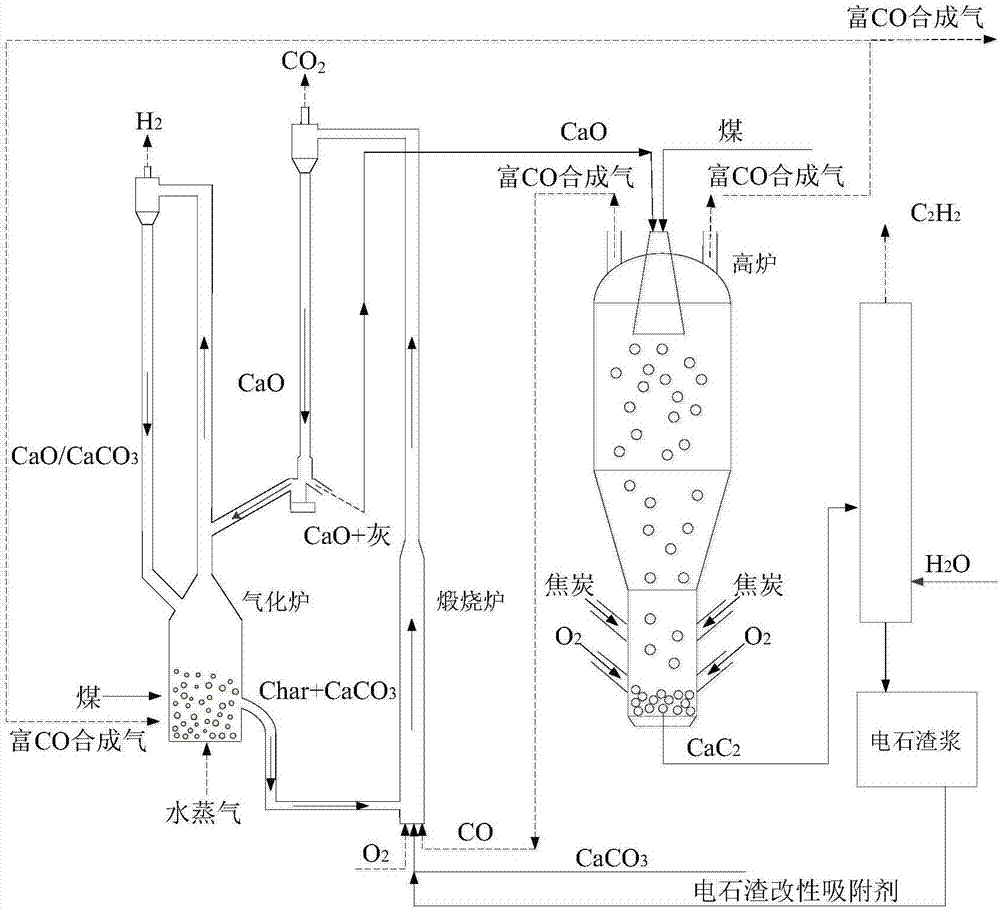

[0026] Such as figure 1 , figure 2 As shown, for the calcium carrier cycle to achieve H 2 -CO-C 2 H 2 Polygeneration Synergy CO 2 Block diagram of the capture process. Using industrial waste calcium carbide slag slurry, ultrasonic-removing impurities to extract calcium hydroxide, and then calcining-screening to obtain calcium-based adsorbent, which is used for coal gasification in a gasifier to produce high-purity hydrogen. After passing through the calciner, the calcium carbonate produced is calcined and decomposed into CaO, and CO is released at the same time. 2 gas. Part of the regenerated calcium-based adsorbent (CaO) is returned to the gasifier for coal gasification, and the other part is used as raw material for the oxythermal blast furnace to prepare calcium carbide. The oxy-thermal blast furnace obtains calcium carbide and at the same time produces by-product...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com