Non-water-based transparent tight film pasting agent and preparation method thereof

A non-water-based, close-fitting technology, applied in coatings, anti-corrosion coatings, etc., can solve problems such as paint stripping, human and environmental pollution, and low transparency, and achieve high transparency, fast drying speed, and good adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

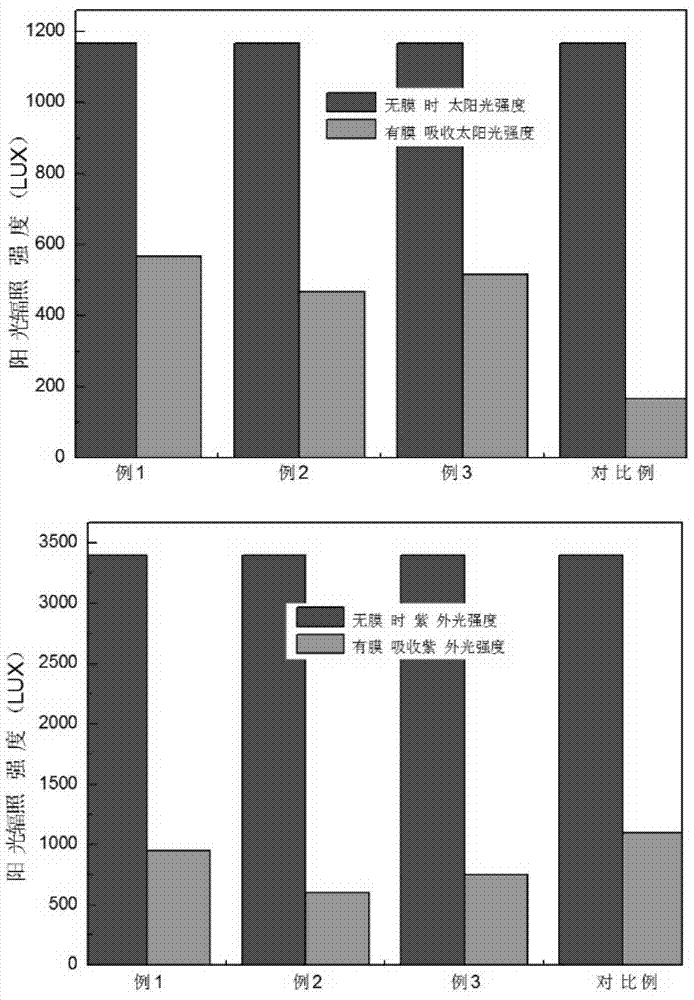

Embodiment 1

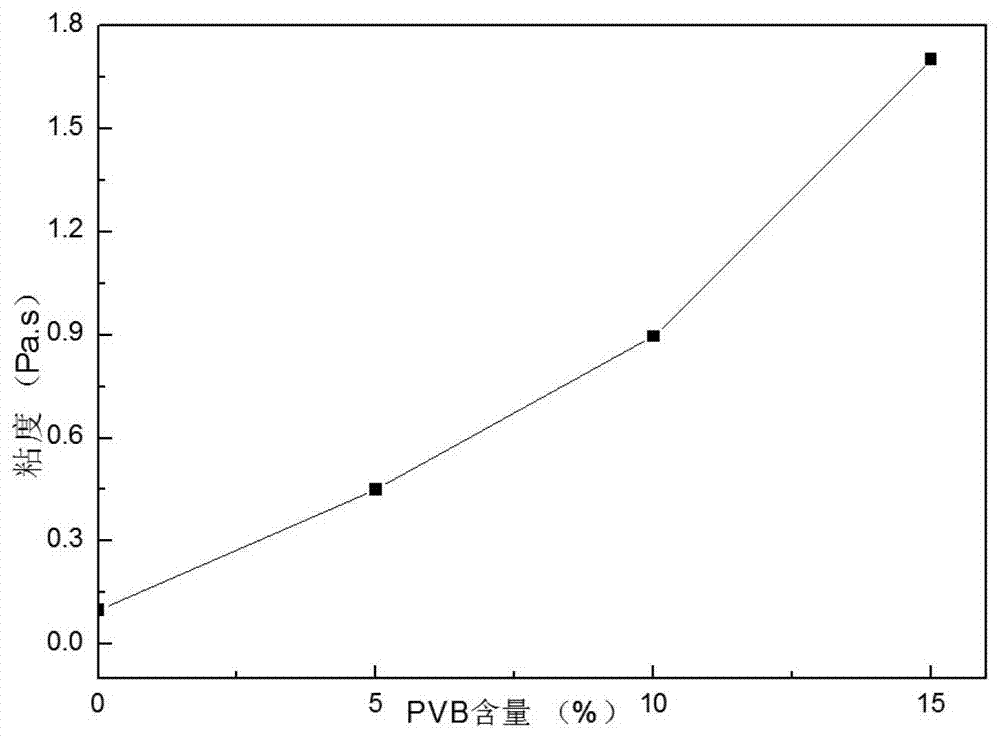

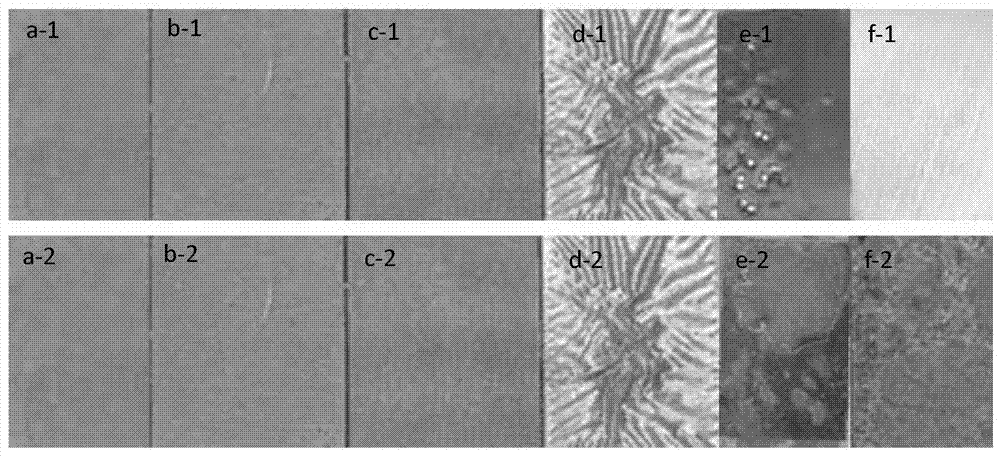

[0030] Firstly, 5wt% polyvinyl butyral was added to 85% ethanol solution in an environment of 25° C., and mechanically stirred for 2 hours. Then add 2% phenolic resin, 3% glycerin, and 5% mixture of butyl acetate and butanone (the mass ratio of butyl acetate and butanone is 1:1), and continue mechanical stirring for 1 h until a transparent liquid is finally formed. Immerse the metal substrate in the antirust agent liquid at room temperature for 1 minute and dry in the air for 2 hours, or dry at 70°C for 30 minutes to obtain an antirust film with a thickness of about 5-20nm on the surface of the metal substrate.

Embodiment 2

[0032] First, add the mixture of 10% cooked linseed oil and soybean oil (cooked linseed oil: soybean oil = 90:100) to 80% ethanol solution in an environment of 50°C, stir mechanically for 2 hours, then add 3% beeswax, and continue mechanically stirring 1h, finally add 3% polyethylene glycol, 4% mixture of butyl acetate and butanone (the ratio of butyl acetate and butanone is 1:1), and continue mechanical stirring for 1h until a turbid liquid is finally formed. Immerse the ceramic substrate into the anti-rust film agent at room temperature for 1 minute, dry in the air for 2 hours, or dry at 70°C for 30 minutes to obtain an anti-rust film with a thickness of about 50-100nm.

Embodiment 3

[0034] Firstly, a mixture of 15% cooked linseed oil and soybean oil (cooked linseed oil:soybean oil=95:100) was added to 75% ethanol solution in an environment of 50° C., and mechanically stirred for 2 hours. Then add 4% phenolic resin, continue mechanical stirring for 1h, finally add 2% glycerin, 4% mixture of butyl acetate and butanone (the ratio of butyl acetate and butanone is 1:1), continue mechanical stirring for 2h, until a thin paste is finally formed. At room temperature, use a short-haired roller brush to coat the wood substrate once, and a film of 50-100nm can be formed. If recoated, a film of about 80-120nm can be formed. Generally, the number of coatings should not exceed three times, otherwise wrinkled skin may form.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com