Environment-friendly energy-saving material and preparation method thereof

An environmental protection, energy saving, raw material technology, applied in ceramic products, other household appliances, applications, etc., to achieve the effect of eliminating odor, hard texture, and improving compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

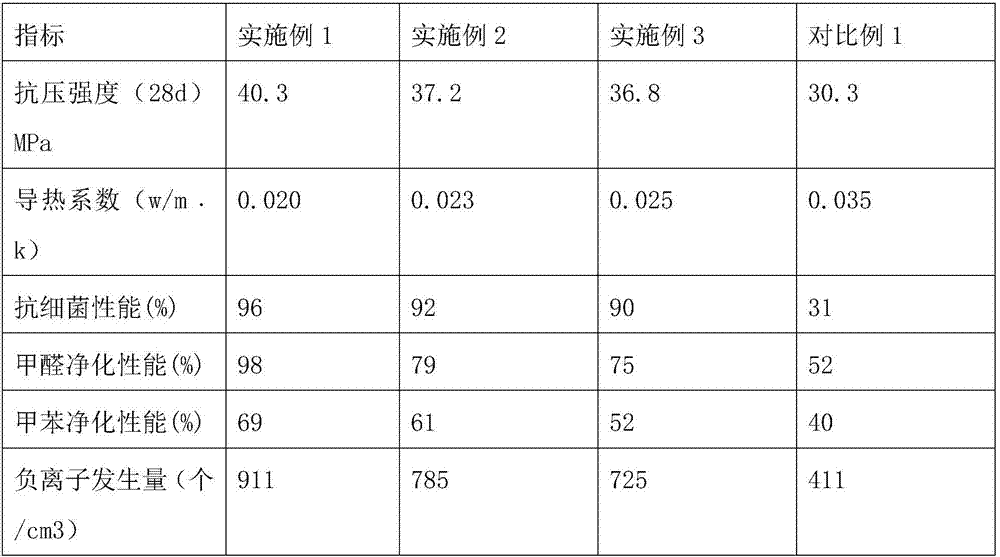

Examples

Embodiment 1

[0037] An environment-friendly and energy-saving material, comprising the following raw materials in parts by weight: 35.5 parts of expanded perlite, 10.5 parts of magnesium oxide, 27.5 parts of cement, 19 parts of urea-formaldehyde resin, 0.85 parts of sodium dodecylbenzenesulfonate, 5.5 parts of negative ion additives, blast furnace 5.5 parts of slag, 9 parts of fly ash, 7.5 parts of shale ash, 17.5 parts of waste polyethylene foam, 17 parts of waste foamed cement, 21.5 parts of waste phenolic foam insulation board, 18 parts of bamboo charcoal, 8 parts of diatomaceous earth, slow 0.3 parts of coagulant, 0.2 parts of air-entraining agent, 0.5 parts of water reducing agent and 4 parts of water.

[0038] The environment-friendly and energy-saving material prepared under the formula has reached the best in terms of compressive strength, thermal insulation performance, respiratory humidity control effect, air purification effect, environmental protection and energy saving.

[003...

Embodiment 2

[0056] An environmental protection and energy-saving material, comprising the following raw materials in parts by weight: 30 parts of expanded perlite, 8 parts of magnesium oxide, 22 parts of cement, 15 parts of urea-formaldehyde resin, 0.5 part of sodium dodecylbenzenesulfonate, 4 parts of negative ion additives, blast furnace 3 parts of slag, 5 parts of fly ash, 6 parts of shale ash, 12 parts of waste polyethylene foam, 15 parts of waste foamed cement, 20 parts of waste phenolic foam insulation board, 15 parts of bamboo charcoal, 5 parts of diatomaceous earth, 0.2 parts of coagulant, 0.1 part of air-entraining agent, 0.3 parts of water reducing agent and 3 parts of water.

[0057] Blast furnace slag, fly ash, shale ash, waste polyethylene foam, waste foamed cement and waste phenolic foam insulation boards are added to the raw materials. These industrial wastes and construction wastes have been left in cities for a long time, not only occupying urban land, but also polluting ...

Embodiment 3

[0074] An environmental protection and energy-saving material, comprising the following raw materials in parts by weight: 41 parts of expanded perlite, 13 parts of magnesium oxide, 33 parts of cement, 23 parts of urea-formaldehyde resin, 1.2 parts of sodium dodecylbenzenesulfonate, 7 parts of negative ion additives, blast furnace 8 parts of slag, 13 parts of fly ash, 9 parts of shale ash, 23 parts of waste polyethylene foam, 19 parts of waste foamed cement, 23 parts of waste phenolic foam insulation board, 21 parts of bamboo charcoal, 11 parts of diatomaceous earth, 0.4 parts of coagulant, 0.3 parts of air-entraining agent, 0.7 parts of water reducing agent and 5 parts of water.

[0075] Blast furnace slag, fly ash, shale ash, waste polyethylene foam, waste foamed cement and waste phenolic foam insulation boards are added to the raw materials. These industrial wastes and construction wastes have been left in cities for a long time, not only occupying urban land, but also pollut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com