Aquatic plant improved concrete

An aquatic plant and concrete technology, applied in the field of building materials, can solve the problems of many internal pore structures, weak seismic performance, poor weather resistance, etc., and achieve the effects of excellent seismic performance, improved shock absorption and seismic performance, and improved cold resistance and thermal insulation performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

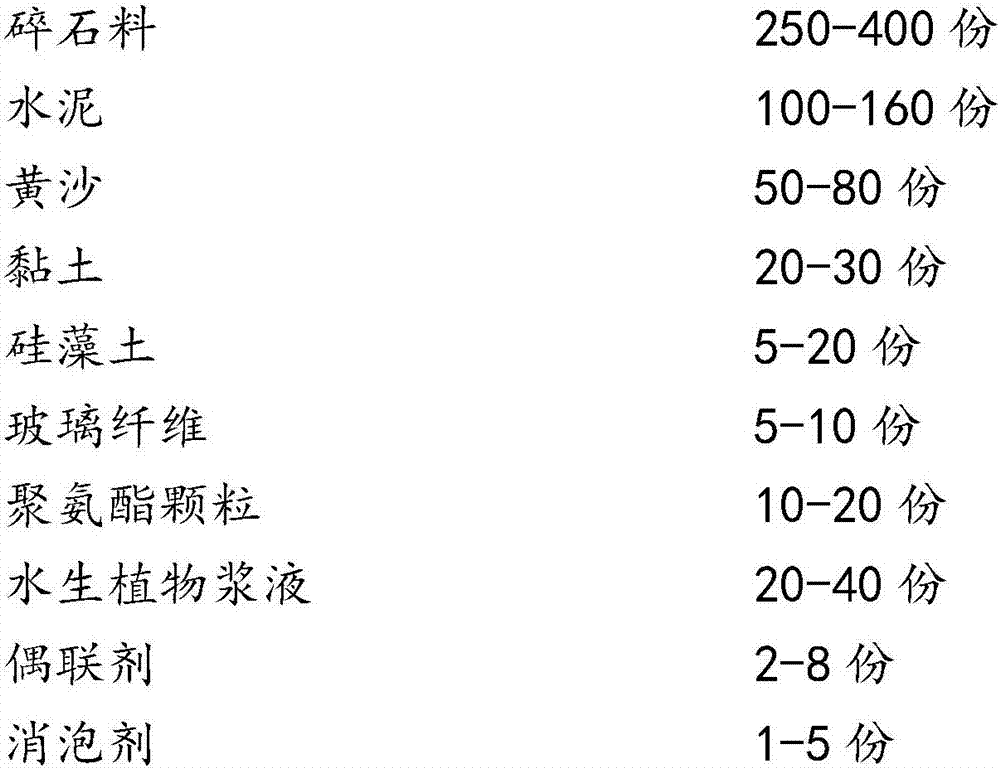

[0015] A kind of concrete improved with aquatic plants, including the following raw materials measured in parts by mass:

[0016]

[0017]

[0018] Wherein, the coupling agent is a silane coupling agent. The cement is Portland cement. The aquatic plant slurry is made from water hyacinth after crushing and stirring. The particle size of the polyurethane particles is less than 1.5mm.

Embodiment 2

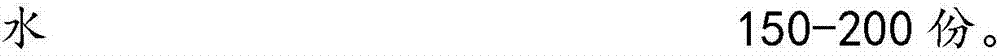

[0020] A kind of concrete improved with aquatic plants, including the following raw materials measured in parts by mass:

[0021]

Embodiment 3

[0023] A kind of concrete improved with aquatic plants, including the following raw materials measured in parts by mass:

[0024]

[0025]

[0026] Wherein, the coupling agent is a silane coupling agent. The cement is phosphate cement. The aquatic plant slurry is made from water hyacinth after crushing and stirring. The particle size of the polyurethane particles is less than 1.5mm. The camphor wood powder is pulverized from camphor wood, and the particle size is less than 600 mesh.

[0027] Through the above specific embodiments, the beneficial effects of the present invention are: the present invention has good structural strength, good toughness, good weather resistance, not easy to crack, good toughness, excellent shock resistance and stable performance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com