Mechanism capable of realizing two times of core pulling and forcible hole stripping operation by virtue of slide

A technology of slider 2 and slider, which is applied in the field of slider secondary core-pulling and strong hole removal mechanism, can solve problems such as the overall structure of the mold, and achieve the effects of reducing the configuration of the mold mechanism, reducing the volume of the mold, and simplifying the structure of the mold

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

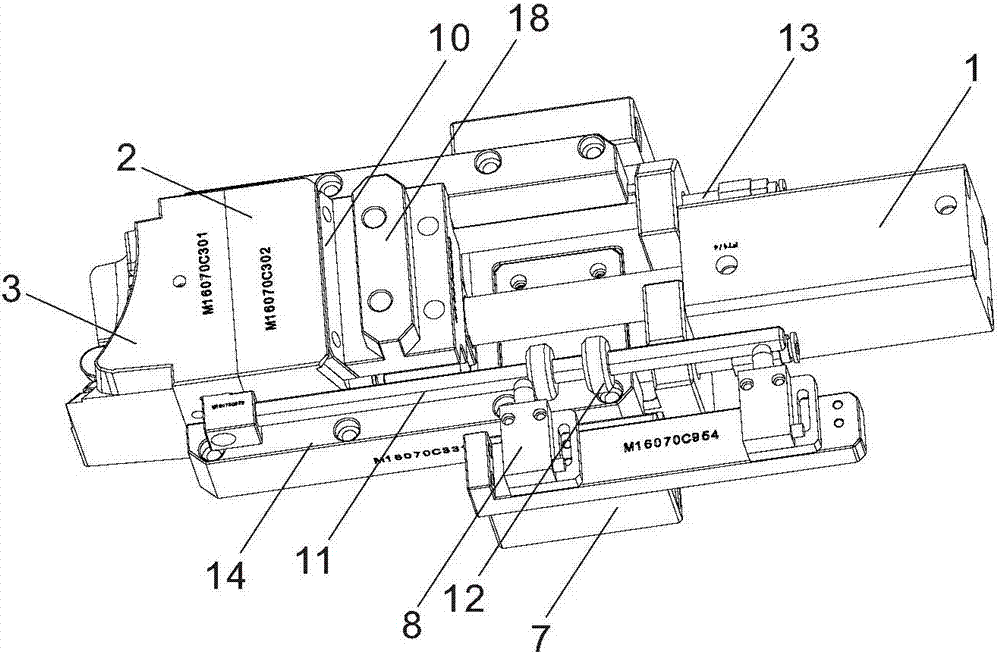

[0029] Such as Figure 1 to Figure 10As shown, a slider secondary core-pulling strong hole removal mechanism is set on the mold. The slider secondary core-pulling strong hole removal mechanism includes an oil cylinder 1, a slider body 2, a slider head 3, and a threaded limit sleeve 4. The outer pin 5 of the U-shaped buckle and the center pin 6 of the U-shaped buckle that can be extended to the mold core, the piston rod of the oil cylinder 1 is connected with the slider body 2, and the slider body 2 and the slider head 3 are slid and connected to each other. On a pair of parallel guide rods 13, the guide rods 13 are fixed on a base frame 7, so that the slider body 2 and the slider head 3 are slidably connected with the base frame 7. The outer pins 5 of the U-shaped buckle are fixed on the slider body 2 and slide through the slider head 3. The outer pins 5 of the U-shaped buckle are arranged in pairs, and there are two pairs in total. The central pin 6 of the U-shaped buckle is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com