Semi-solid horizontal extrusion mold for double-layer composite pipes and application thereof

A double-layer composite, horizontal extrusion technology, applied to metal extrusion dies and other directions, can solve problems such as poor inner surface quality, and achieve the effects of good reusability, simple processing process and easy production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

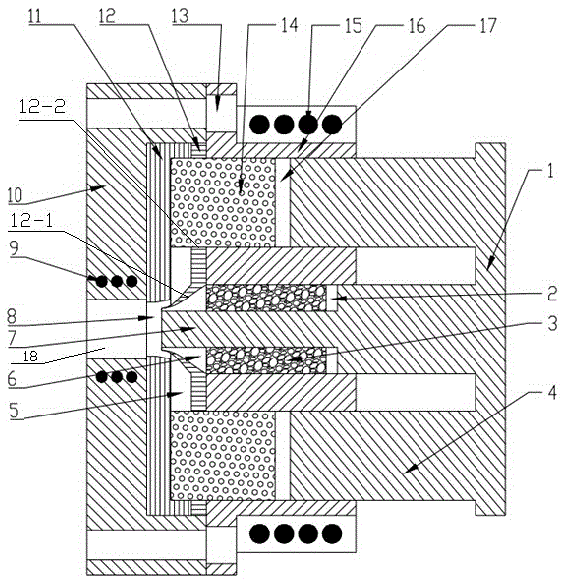

[0027] 1. Mould structure description:

[0028] Such as figure 1 As shown, the semi-solid horizontal extrusion die of the double-layer composite pipe of the present invention is composed of a base 10, an extrusion sleeve 16, an extrusion rod 1, an inner extrusion die 12, and an outer extrusion die 11.

[0029] A groove is provided on the right side of the base 10, the outer extrusion die 11 and the inner extrusion die 12 are respectively placed in the groove, the outer periphery of the outer extrusion die 11 is provided with a boss, and the inner extrusion die 12 is arranged outside the groove, And it is placed on the boss of the outer extrusion die 11. An extrusion hole 8 is provided on the outer extrusion die 11, and the surface of the extrusion hole 8 is provided with a first flow guiding curved surface.

[0030] A cylindrical shaped tube outlet 18 concentric with the extrusion hole 8 is provided on the base 10, and the diameter of the shaped tube outlet 18 is slightly larger th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com