Fender-guard mounting structure

A technology for mounting structures and bumpers, which is applied to bumpers and other directions, can solve problems such as reducing the service life of molds, inconvenient control of bumper appearance gaps, and increasing the complexity of bumper molds, so as to improve installation efficiency and simplify mold structures. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

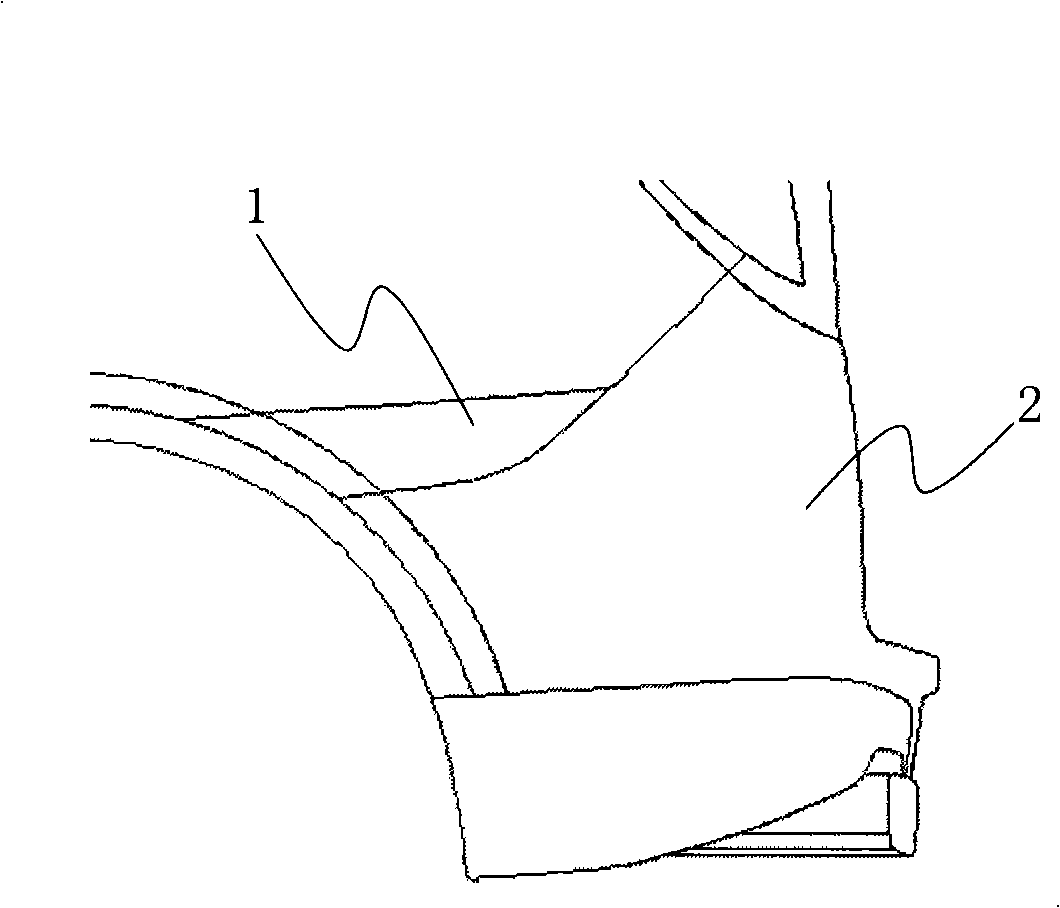

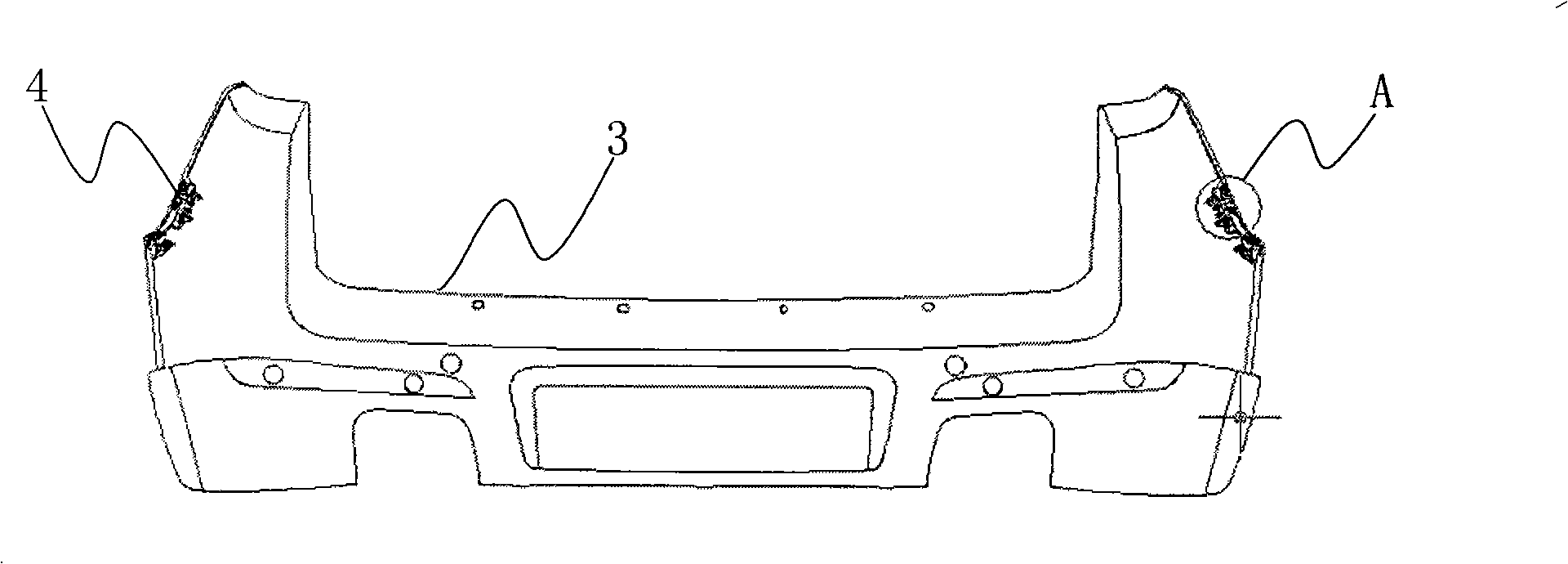

[0013] Such as figure 1 , 2 As shown, a bumper mounting structure, the present invention includes a connecting piece 4 that is fixedly connected with the vehicle body 1, and the connecting piece 4 is provided with a limiting portion that limits the horizontal and vertical movement of the bumper 2. The bumper 2 is combined with the vehicle body 1 through the connecting piece 4.

[0014] The fixed connection between the connecting piece 4 and the vehicle body 1 can be realized in various ways, such as inlaid fit or bolted connection. As a preferred solution of the present invention, the connecting piece 4 and the vehicle body 1 are connected by bolts. The connection method is quick to install and accurate in positioning. In order to prevent the car body 1 from scratches and scratches during installation, the connecting piece 4 can be connected with the car body 1 in a manner of matching plastic nut seats and self-tapping screws.

[0015] The connection assembly of bumper 2 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com