Method for inhibiting tail-end residual oscillation of four-degree-of-freedom cylindrical coordinate type palletizing robot

A stacking robot and cylindrical coordinate technology, applied in the direction of manipulators, manufacturing tools, etc., can solve the problems of reducing work efficiency, prolonging robot positioning time, residual vibration, etc., achieving easy implementation, improving repeat positioning accuracy and work efficiency, simple and reliable Achieved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

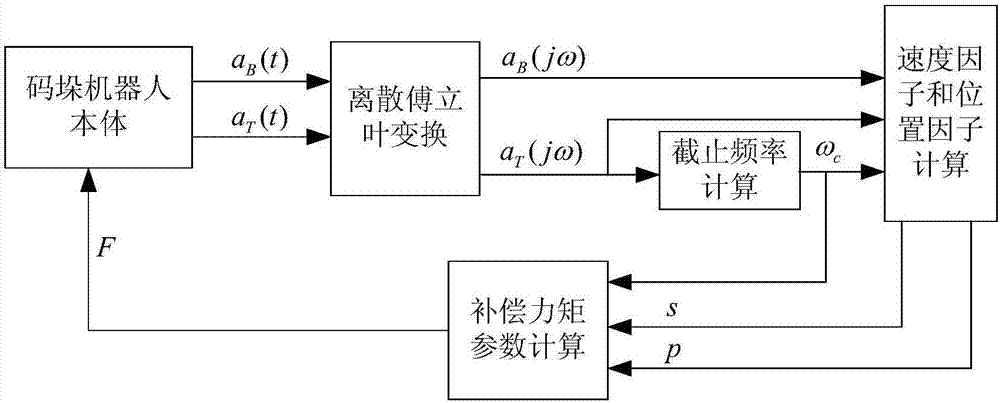

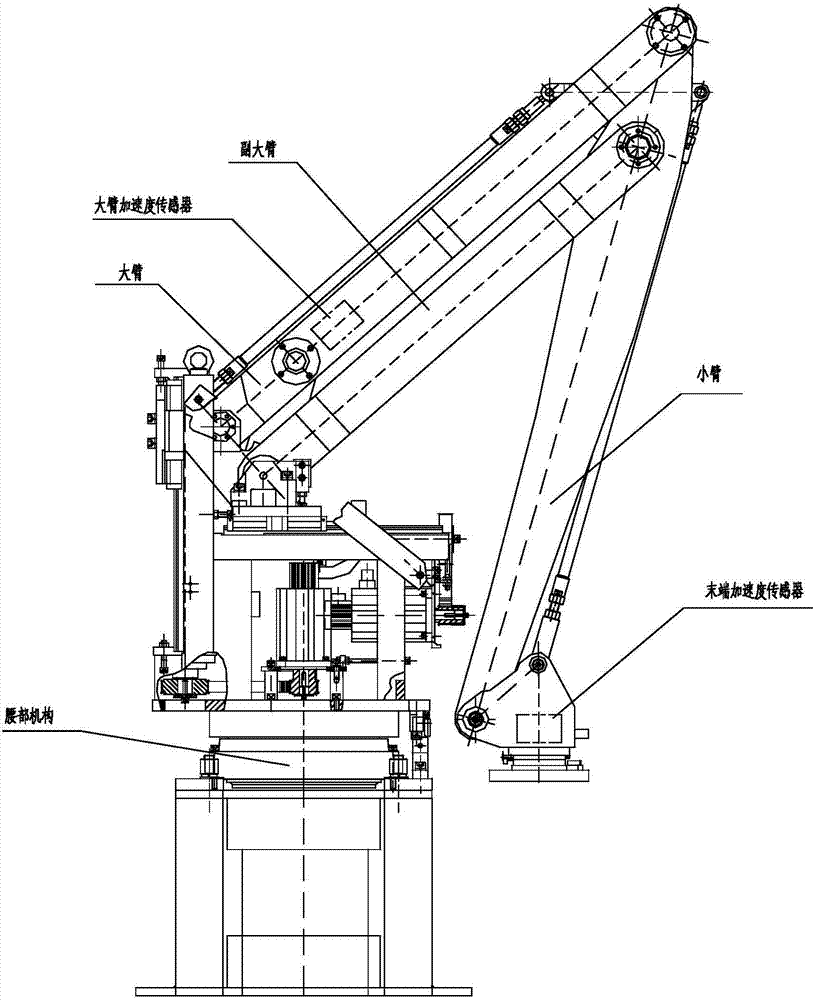

[0033] Such as figure 1 , figure 2 As shown, this embodiment provides a method for suppressing residual vibration at the end of a four-degree-of-freedom cylindrical coordinate palletizing robot. Acceleration sensors are respectively installed on the boom and the end of the four-degree-of-freedom cylindrical coordinate palletizing robot, including the following step:

[0034] Step 1. When the end of the four-degree-of-freedom cylindrical coordinate palletizing robot reaches a certain positioning point, the first to nth compensation moments are applied to the servo motor of the waist rotary joint of the four-degree-of-freedom cylindrical coordinate palletizing robot.

[0035] The expression of compensation torque is F=ga T (t-τ) (1)

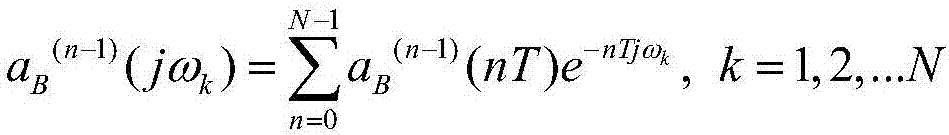

[0036] Among them, F is the compensation torque, g is the proportional coefficient of the compensation torque, τ is the time constant of the compensation torque, a T (t) is the measured value of the acceleration sensor installed on the end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com