Heavy hydraulic four-hammer radial forging tool

A radial forging, four-hammer technology, applied in the field of forging tools, can solve the problems of low forging accuracy, large machining allowance, large equipment investment, etc., to improve forging accuracy and quality, reduce machining allowance, and reduce production costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

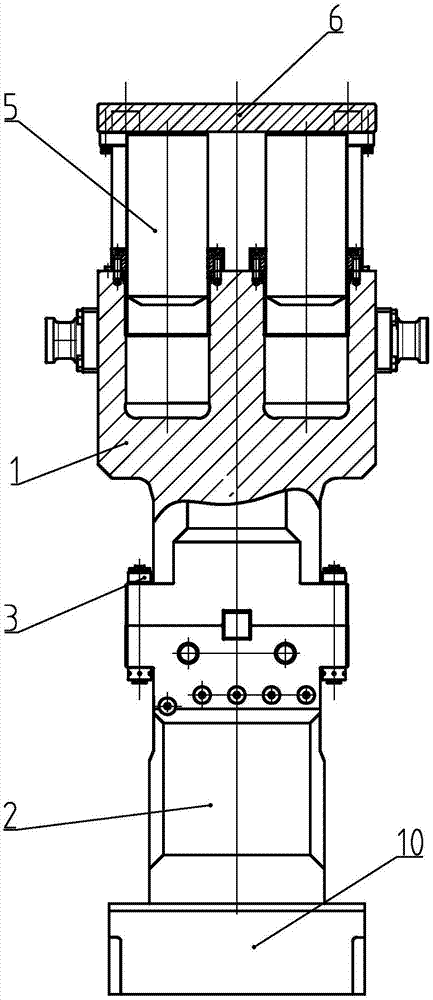

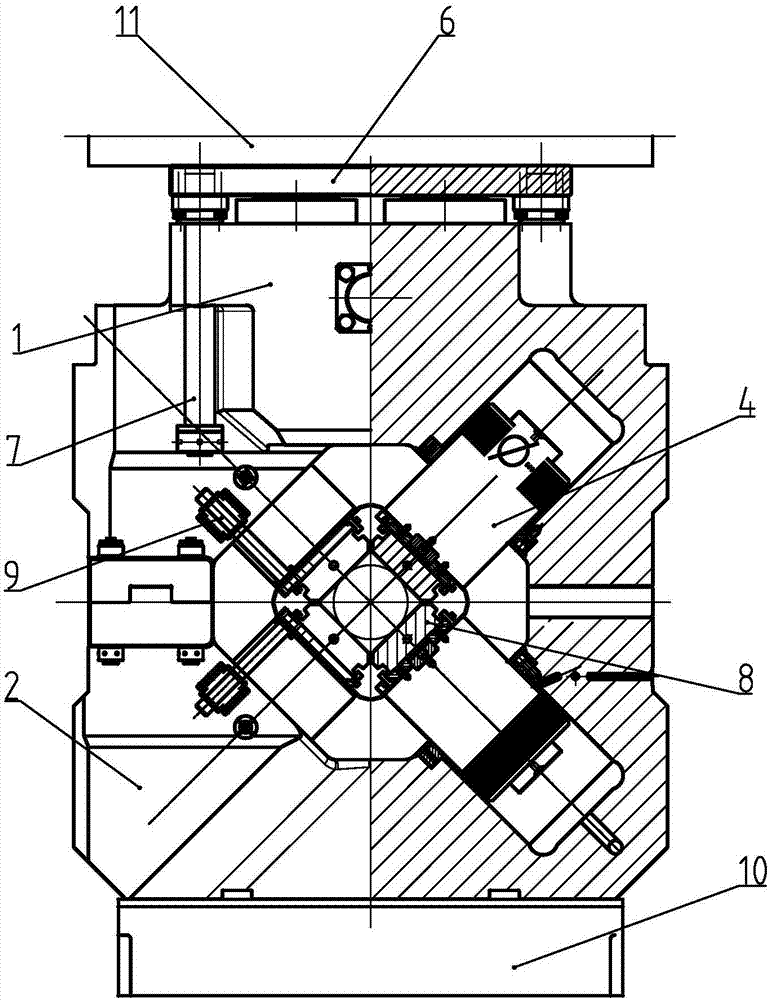

[0024] The present invention will be further described below in conjunction with accompanying drawing. Such as Figure 1-4 Shown, the specific embodiment of the present invention is such as Figure 1-4 As shown, the heavy-duty hydraulic four-hammer radial forging tool for forging heavy-duty shafts is composed of an upper frame 1, a lower frame 2, a pre-tightening bolt 3, a hammer cylinder 4, a plunger cylinder 5, an upper platen 6, The guide column 7, the hammer head 8, and the hammer head anti-rotation device 9 are fixed on the workbench 10 of the forging hydraulic press when in use, and the upper frame 1 and the lower frame 2 are connected by pre-tightening bolts 3 to form a closed frame , to withstand the force generated during the forging process, the four hammerheads 8 are connected with the hammerhead cylinders 4, and arranged on the upper and lower frames in an "X shape"; the piston chambers of the four hammerhead cylinders 4 are connected with the top four The plunge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com