Continuous-flow tubular reaction system and reaction control system

A tubular reaction and flow controller technology, which is applied in chemical/physical/physical chemical fixed reactors, control/regulation processes, chemical/physical/physical chemical processes, etc., can solve the problem of inability to achieve precise temperature control and online Monitoring, large footprint, mass transfer, heat transfer and mixing are not uniform enough to achieve the effect of low production cost, small volume and floor space, and increased length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

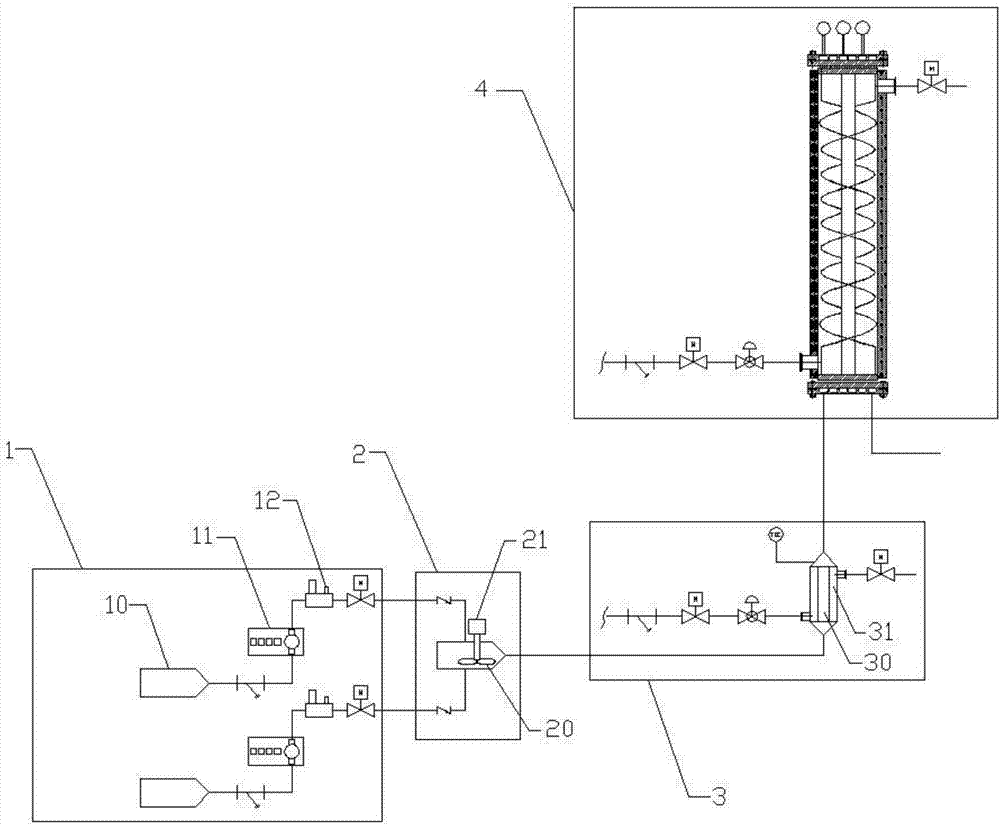

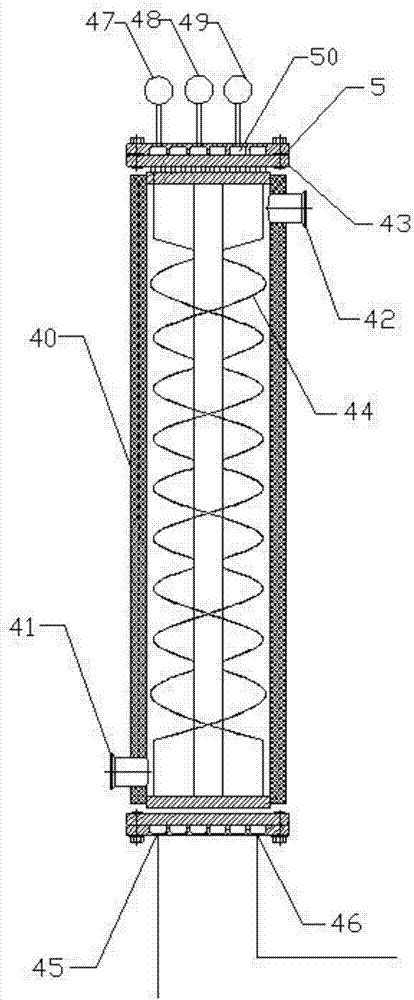

[0030] Such as Figure 1-2 As shown, the continuous flow tubular reaction system of this embodiment includes a feeding device 1 , a mixing device 2 , a preheating device 3 and a reaction device 4 connected in sequence.

[0031] Wherein, the feeding device 1 comprises a plurality of sequentially connected raw material tanks 10, feed pumps 11 and flow controllers 12, each raw material tank 10 is used to hold a reaction solution, and the flow controller 12 is used to control the feeding The pump 11 draws the reaction solution from the raw material tank 10 at a certain rate.

[0032] A stirring paddle 20 is installed in the mixing device 2, and the stirring paddle 20 is driven by a servo motor 21 for mixing the reaction solution extracted from the raw material tank 10 to obtain a mixed solution.

[0033] The preheating device 3 includes a preheating tube side 30 and a preheating shell side 31, the preheating tube side 30 is used for circulating the mixed solution introduced from ...

Embodiment 2

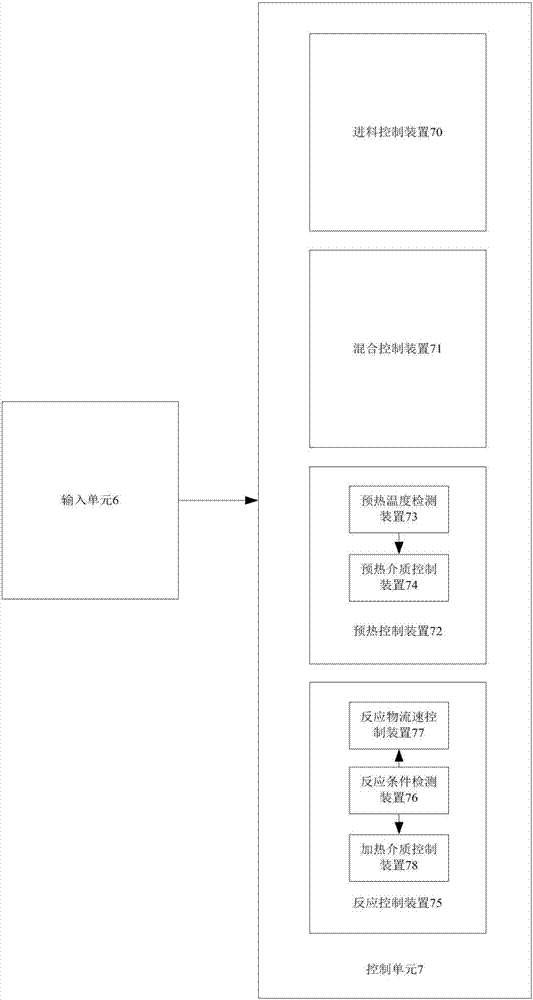

[0040] This embodiment discloses a continuous flow tube reaction control system, including an input unit 6 and a control unit 7, the input unit 6 is used to select a preset reaction mode, and the control unit 7 is selected based on the input unit 6 The reaction mode is used to output control signals to control the operation of the continuous flow tubular reaction system; wherein, the control unit 7 includes:

[0041] Multiple groups of feed control devices 70, each group of feed control devices 70 are connected to a raw material tank 10 for controlling the flow rate and flow rate of each reaction solution;

[0042] a mixing control device 71, configured to control the rotational speed of the servo motor 21;

[0043]The preheating control device 72 includes a preheating temperature detection device 73 and a preheating medium control device 74, the preheating temperature detection device 73 is used to detect the temperature of the preheating solution in the preheating tube 30 of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com