A kind of preparation method of microneedle system

A microneedle and silicone rubber technology, applied in the field of microneedle systems, can solve the problems of low electrical signal quality, expensive equipment, and increased production costs, and achieve the effects of fast and simple preparation methods, increased applicability, and improved quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

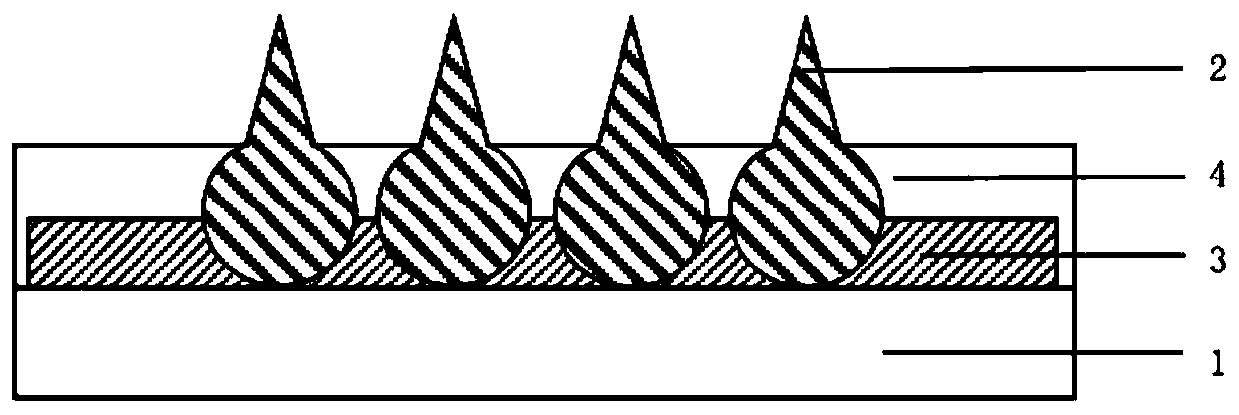

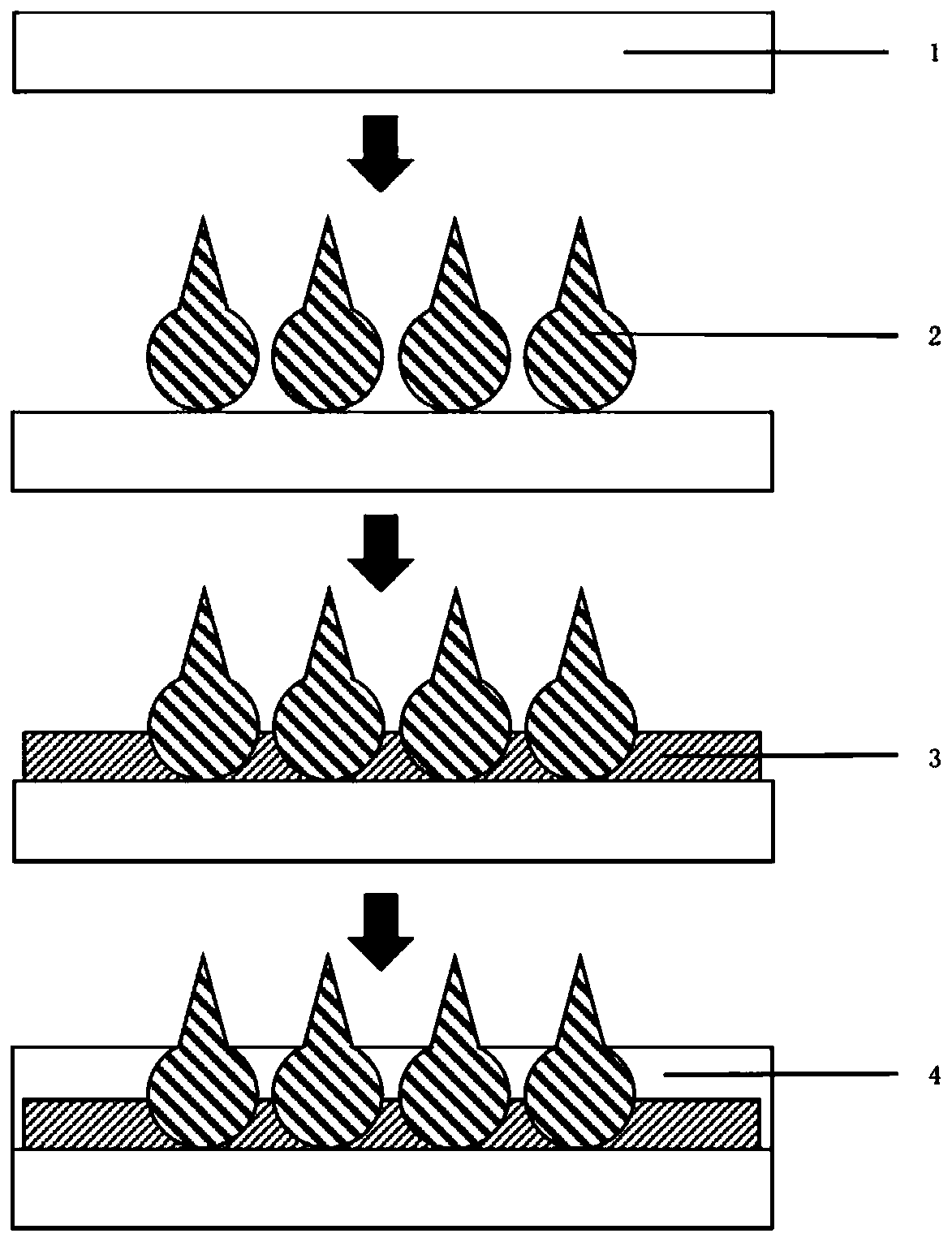

[0022] The preparation method of the microneedle system provided by the present invention comprises the following steps:

[0023] 1) Making the base: Mix the silicone rubber pre-preparation and its curing agent, stir well and vacuumize for more than 10 minutes to remove air bubbles, then pour the liquid silicone rubber with the curing agent on the petri dish, and place it in an oven for heating Curing for more than 1 hour, and then tearing off the cured solid silicone rubber from the petri dish;

[0024] 2) Making microneedles: Heat the low-melting point liquid alloy to above 60°C to liquid state, pour it into the syringe of the dispensing machine, place the flexible silicone rubber base under the needle of the dispensing machine, set the shape of the dispensing array, z Axis speed (10mm / s-180mm / s), syringe dwell time (0.1s-2s) and sample ejection time (0.1s-2s) before dispensing;

[0025] 3) Making a conductive layer: spraying gallium-indium alloy onto the surface of the mic...

Embodiment 1

[0029] 1) Make the substrate: Mix the polydimethylsiloxane prepolymer and the curing agent at a volume ratio of 10:1, stir well and vacuumize for 10 minutes to remove air bubbles, and then put the liquid polydimethylsiloxane prepolymer with the curing agent The siloxane was poured onto the petri dish, and dried in an oven at 80° C. for 2 hours to obtain a solid polydimethylsiloxane substrate, which was torn off from the petri dish.

[0030] 2) Making microneedles: heat the bismuth-indium-tin-zinc alloy with a melting point of 57.5°C to 80°C to a liquid state, pour it into the syringe of the dispenser, place the flexible silicone rubber base under the needle of the dispenser, and use the program to set The shape of the fixed-point glue array is 6x6, the interval between two microneedles is 0.8 mm, the z-axis speed is 30 mm / s, the residence time of the syringe is 0.2 seconds, and the sample output time is 0.3 seconds, and then the program is run for dispensing.

[0031] 3) Makin...

Embodiment 2

[0034] 1) Make the substrate: Mix the polydimethylsiloxane prepolymer and the curing agent at a volume ratio of 10:1, stir well and vacuumize for 10 minutes, remove the air bubbles, and then add the curing agent to the liquid The polydimethylsiloxane was poured onto the petri dish, and placed in an oven at 80°C for 2 hours to obtain a solid polydimethylsiloxane substrate, which was then torn off from the petri dish.

[0035] 2) Making microneedles: heat the bismuth-indium-tin-zinc alloy with a melting point of 57.5°C to 80°C to a liquid state, pour it into the syringe of the dispenser, place the flexible silicone rubber base under the needle of the dispenser, and use the program to set The shape of the fixed-point glue array is 4x4, the interval between the two microneedles is 2 mm, the z-axis speed is 30 mm / s, the residence time of the syringe is 0.2 seconds, and the sampling time is 0.3 seconds, and then the program is run for dispensing.

[0036] 3) Making the conductive la...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com