Lactobacillus plantarum and application thereof to silage preparation

A technology of Lactobacillus plantarum and silage, applied in the field of Lactobacillus plantarum and its application in the preparation of silage, can solve the problems of slow growth of lactic acid bacteria, low acid production, and low quality of silage, and achieve accelerated fermentation process and low cost , the effect of lowering the pH value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

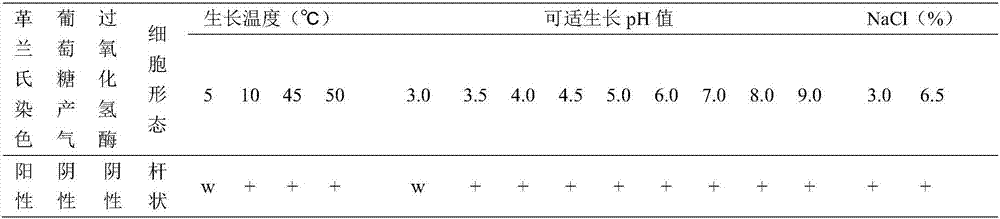

[0033] Example 1: Isolation and strain identification of Lactobacillus plantarum CAU-a214

[0034] 1. Isolation of strains

[0035] Separation of Lactobacillus plantarum by dilution plate method: add 10 g of alfalfa silage 60-day samples to 90 mL of sterilized distilled water to shake evenly, dilute 10 times in a gradient, and then take 10 -1 、10 -3 and 10 -5 20 μL of each sample dilution was spread on the MRS medium, and incubated in a 30°C constant temperature incubator for 48 hours; according to the characteristics of colony size, shape and color, typical colonies were picked, and catalase activity determination, Gram staining and Microscope test. All strains that are Gram-positive and catalase-negative can be initially identified as Lactobacillus, and they are streaked and purified twice on MRS medium, and then stored in 1ml of NB cultured with 10% DMSO stored in a -80°C ultra-low temperature freezer.

[0036] MRS medium: 10.0g of peptone (Proteose peptone NO.3); 10.0...

Embodiment 2

[0066] Embodiment 2: the preparation of alfalfa silage

[0067] The preparation of alfalfa silage comprises the following steps:

[0068] (1) Dry the alfalfa to a moisture content of about 60%, cut it to 1cm-2cm, and mix well;

[0069] (2) To step (1) alfalfa according to 6log cfu g -1 Lactobacillus plantarum (Lactobacillus plantarum) CAU-a214 was inoculated, and no addition (Control), GFG (commercial bacterial agent), FG1 (commercial bacterial agent) were used as controls, and each treatment was repeated 3 times;

[0070] (3) Put the alfalfa from step (2) into polyethylene silage bags of 30cm×20cm, and process three bags for each bag, with 100g in each bag, pump air with a vacuum sealing machine, seal, and store at room temperature for 60 days.

[0071] Nutrient components, fermentation quality, microbial analysis and in vitro digestion experiments were carried out after alfalfa silage for 60 days.

[0072] 1. Identification of nutritional components and fermentation quali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com