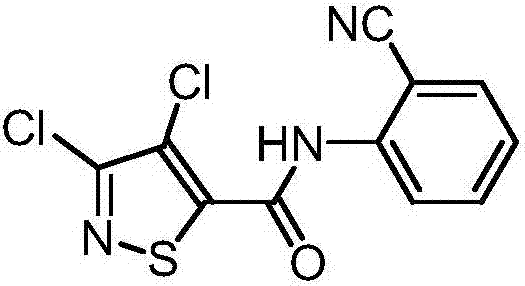

Composition containing isotianil and fine furalaxyl

A technology of Isotianil and its composition, which is applied in the field of composition containing Isotianil and furaxyl, pesticide composition, and prevention and control of plant diseases and insect pests, and can solve problems such as not being able to solve plant diseases and insect pests well

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Example 1: 38% emulsifiable concentrate

[0025] The formula is composed of: 28% of active ingredient A, 10% of active ingredient B, 4% of castor oil polyoxyethylene ether as an emulsifier, 6% of calcium lauryl sulfate as an emulsifier, and 100% of xylene as a solvent.

[0026] The preparation method is as follows: put all the materials into the batching kettle, stir and dissolve until completely transparent, and transfer to the storage tank for filling after passing the test.

Embodiment 2

[0027] Embodiment 2: 12% seed treatment suspending agent

[0028] The formula is composed of: active ingredient A is 6%, active ingredient B is 6%, wetting agent fatty alcohol polyoxyethylene ether 4%, dispersant maleic acid-acrylic acid copolymer sodium salt 5%, antifreeze agent ethylene glycol 4% %, thickener magnesium aluminum silicate 0.2%, alert rose essence 0.8%, water to make up to 100%.

[0029] The preparation method is as follows: put the active ingredient, wetting agent, dispersant, antifreeze, warning color and water into the stirring tank, after fully stirring, pump the material into the sand mill for full grinding, after the grinding is completed, pump into the high-speed shear In the cutting machine, after adding the thickener, high-speed shearing is carried out, and the seed treatment suspending agent is obtained after the shearing is completed.

Embodiment 3

[0030] Example 3: 75% water dispersible granules

[0031] The formula is composed of: 20% active ingredient A, 55% active ingredient B, 5% wetting agent pull-off powder, 6% dispersant fatty alcohol polyoxyethylene ether sodium sulfate, 5% disintegrating agent ammonium sulfate, binder Carboxymethyl cellulose 0.2%, filler attapulgite to make up to 100%.

[0032] The preparation method is as follows: after all the materials are mixed uniformly, pulverized by an airflow mill, mixed uniformly again, and then a certain amount of water is added to knead the mixture, extruded and granulated, and dried and sieved to obtain the water-dispersible granules.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com