Luminous decay resistant furnace

A light decay furnace and light decay technology, applied in sustainable manufacturing/processing, electrical components, climate sustainability, etc., can solve problems such as weak passivation, and achieve obvious effects, high output power, and suppression of light decay. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below according to the accompanying drawings and specific embodiments, but the embodiments of the present invention are not limited thereto.

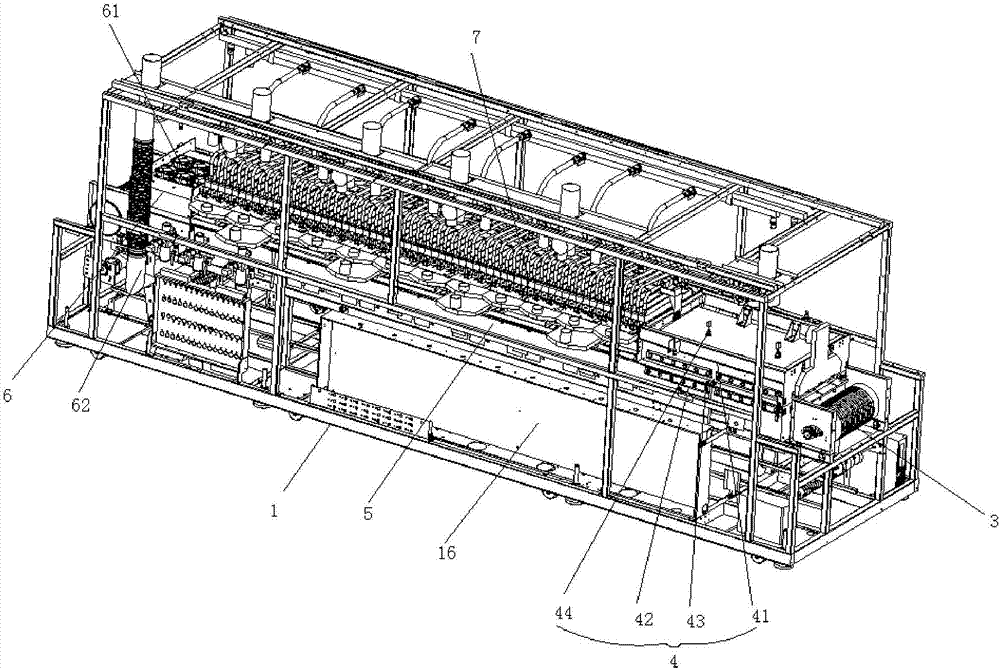

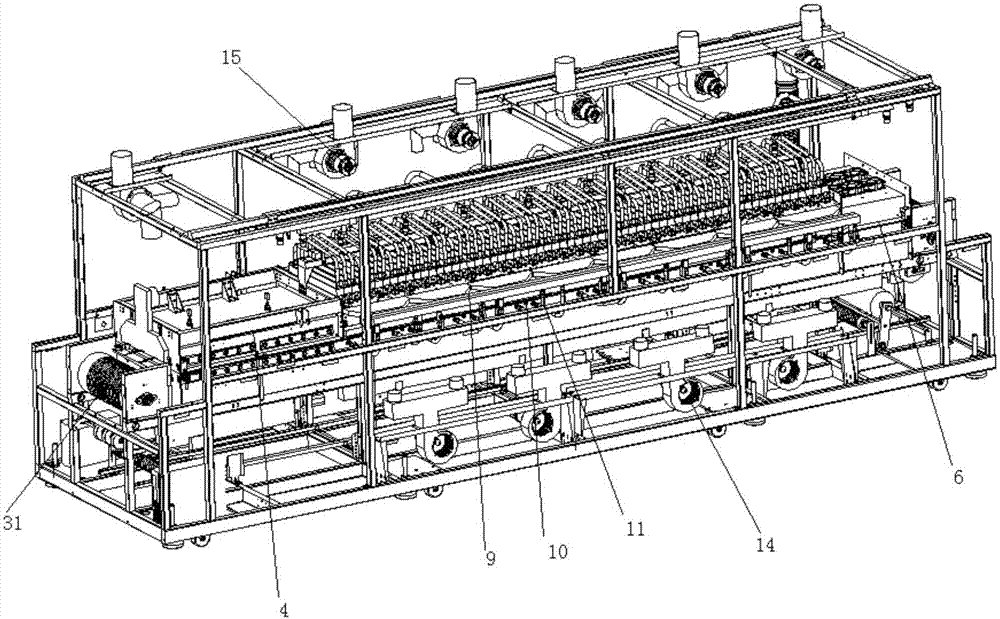

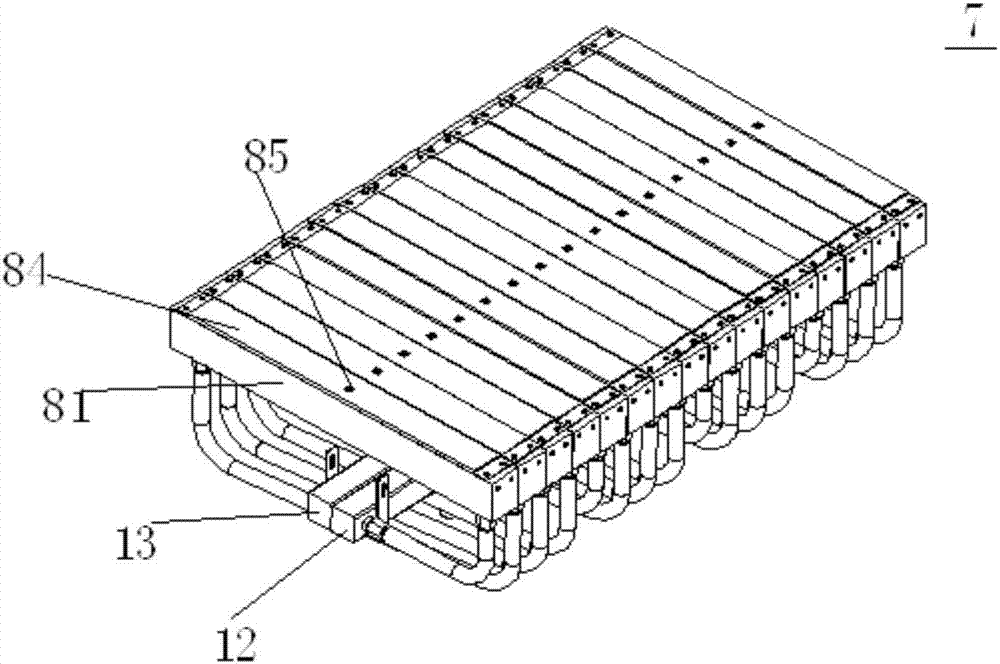

[0042] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 and Figure 8 As shown, an anti-light decay furnace includes a furnace support 1 and a plurality of constant current sources 2. The furnace support 1 is provided with a conveying device 3 for circularly conveying silicon wafers. The furnace support 1 is along the feeding end of the conveying device 3 to the discharge A preheating zone 4, a lighting zone 5 and a cooling zone 6 are provided in sequence at the end of the lighting zone 5, and several groups of LED lighting modules 7 arranged side by side are arranged directly above the lighting zone 5, and each group of LED lighting modules 7 is composed of multiple water-cooled It consists of functioning LED light bars 8, and each LED ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com