Metal cleaning agent

A metal cleaning agent and builder technology, applied in the field of metal cleaning agents, can solve the problems of ozone layer destruction, flammability, and pollution in chemical cleaning, and achieve perfect decontamination process, prevent recondensation, and good cleaning ability

Inactive Publication Date: 2017-08-15

山东龙港硅业科技有限公司

View PDF7 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the above-mentioned first three cleaning agents all have different defects. For example, solvent cleaning will directly pollute the air and destroy the ozone layer of the atmosphere due to the volatilization of organic solvents. It is flammable, explosive, and unsafe; chemical cleaning also pollutes and corrodes the equipment. , unsafe for workers, and the scope of use is narrow; therefore, it is necessary to develop a cleaning agent with low cleaning cost, safe use, and no pollution to the environment, which has become the main development direction of the metal cleaning industry

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

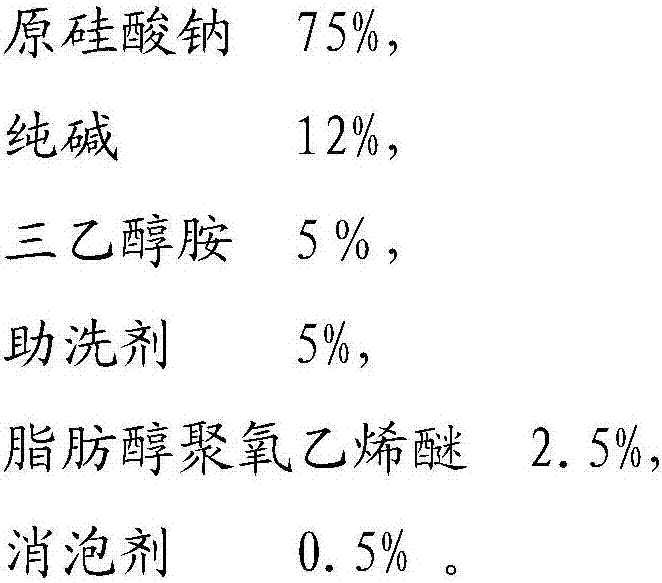

[0022] A metal cleaning agent comprising the following components by weight percentage:

[0023]

Embodiment 2

[0025] A metal cleaning agent comprising the following components by weight percentage:

[0026]

Embodiment 3

[0028] A metal cleaning agent comprising the following components by weight percentage:

[0029]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention belongs to the technical field of metal cleaning agents and particularly relates to a metal cleaning agent. The metal cleaning agent comprises, by weight, 60-80% of sodium orthosilicate, 12-30% of sodium carbonate, 4-10% of triethanolamine, 3-8% of washing assistants, 1-2.5% of fatty alcohol-polyoxyethylene ether and 0.5-1% of defoaming agents. The metal cleaning agent has the good performances of wetting, permeation, emulsification, dispersing and solubilizing, and is good in cleaning effect, free of pollution, short in cleaning time and high in detergency.

Description

technical field [0001] The invention belongs to the technical field of metal cleaning agents, and in particular relates to a metal cleaning agent. Background technique [0002] Metal cleaning is one of the indispensable processes in mechanical processing, because in different metal processing processes, various types of dirt may adhere to the surface of metal parts and equipment. Only by fully cleaning these dirt can the next process be guaranteed. The smooth progress and the processing quality of the product. [0003] At present, chemical pickling (mainly removing metal oxides), chemical alkali cleaning (removing animal and vegetable oils), organic solvent cleaning (relying on solvents to dissolve dirt) and water-based cleaning are often used for different types of dirt. However, the above-mentioned first three cleaning agents all have different defects. For example, solvent cleaning will directly pollute the air and destroy the ozone layer of the atmosphere due to the vol...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C23G5/036

CPCC23G5/036

Inventor 王敬伟张福顺纪发达聂梓新

Owner 山东龙港硅业科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com