Graphene-butadiene-acrylonitrile latex compound slurry and preparation method and application thereof

A composite slurry, graphene technology, applied in other household appliances, applications, household components and other directions, can solve the problems of human injury, poor anti-static performance, etc., achieve good anti-aging performance, good oil resistance, and small tensile stress Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The present embodiment relates to a kind of graphene-nitrile latex composite slurry and preparation method thereof; The preparation of nitrile latex comprises the steps:

[0041]Step 1. Sulfur 1kg, zinc oxide 4kg, accelerator (zinc dibutyldithiocarbamate) 1kg, antioxidant (2-6-di-tert-butyl p-cresol) 0.4kg, ethylamine 0.35kg, dispersed Agent (sodium methylene bis-naphthalene sulfonate) 0.4kg, casein 1kg, demineralized water 7.5kg mix uniformly, ball milling speed is 40 revs / min, and ball milling time is 72 hours, forms standby ball milling sulfur material;

[0042] Step 2, in 1 ton of nitrile rubber, add bromododecane modified graphene oxide and synergist ethanolamine, its weight ratio is 100: 0.2: 0.1, mix uniformly, get graphene-nitrile latex;

[0043] Step 3, adding 50 kg of ball-milled sulfur material to be used in the graphene-nitrile latex, stirring for 4 hours, parking for 24 hours, and pre-vulcanizing;

[0044] Step 4, add filler (calcium carbonate) to the slur...

Embodiment 2

[0054] This embodiment relates to a kind of graphene-nitrile latex composite slurry and preparation method thereof; The preparation step of nitrile latex is the same as embodiment 1, and difference is:

[0055] In step 2, in 1 ton of nitrile rubber, add cationic surfactant modified graphene oxide (hexadecyltrimethylammonium chloride modified graphene oxide) and synergist Span, its weight ratio is 100 : 0.025: 0.01, mixed uniformly to obtain graphene-nitrile latex;

[0056] In step 4, add filler (calcium carbonate) and stir after 3 hours in the slurry that pre-vulcanization obtains, add the titanium dioxide slurry that accounts for 3% of acrylonitrile-butadiene rubber weight and stir until even; Described titanium dioxide slurry is the mass ratio It is formed by separate ball milling of 1:1 titanium dioxide and soft water for 72 hours.

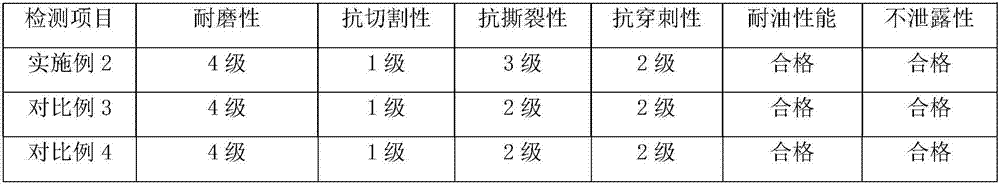

[0057] The nitrile latex that does not add cationic surfactant modified graphene oxide is marked as comparative example 3; The graphene-nitri...

Embodiment 3

[0062] The present embodiment relates to a kind of graphene-nitrile latex composite slurry and preparation method thereof; The preparation steps of nitrile latex are the same as embodiment 2, the difference is:

[0063] Step 1. Sulfur 2kg, zinc oxide 11.2kg, accelerator (zinc dibutyldithiocarbamate) 3.2kg, antioxidant (2-6-di-tert-butyl p-cresol) 1.6kg, ethylamine 1.2kg 1.6kg of dispersant (sodium methylene bis-naphthalene sulfonate), 3.2kg of casein, 16kg of demineralized water are mixed evenly, and the ball milling speed is 50 revs / min, and the ball milling time is 48 hours to form the standby ball milling sulfur material;

[0064] Step 2, in 1 ton of nitrile rubber, add amino polymer modified graphene oxide (adopting triethylenetetramine and ethylenediamine, graphene oxide is modified with condensation agent method) and synergist Tween, its The weight ratio is 100:5:0.2, mixed uniformly to obtain graphene-nitrile latex;

[0065] Step 3, add 40kg of ball-milled sulfur mater...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com