Anti-clay polymer dispersing agent and preparation method thereof

A polymer and anti-clay technology, which is applied in the field of concrete admixtures, can solve the problems of poor anti-clay performance and limited industrialization, and achieve the effect of improving mud resistance, simple synthesis process, and enhanced adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

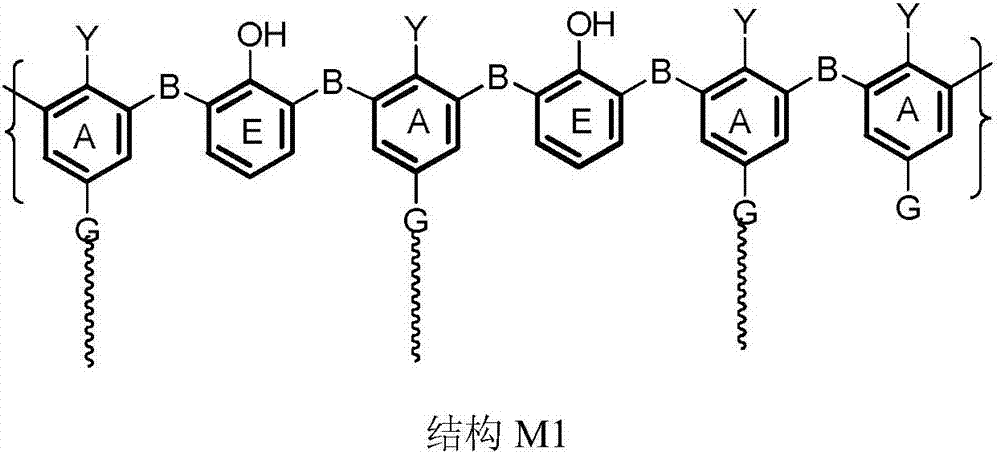

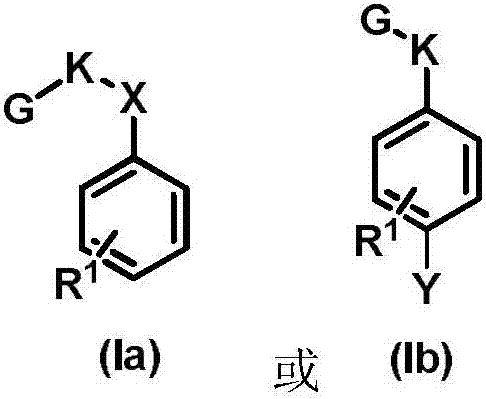

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] In this embodiment, B / (A+D)=1:1, A / D=2.0.

[0067] (1) Polycondensation reaction

[0068] Add 27.6g (0.2mol) of p-hydroxybenzoic acid A and 12.5g (0.125mol) of sulfuric acid C into a 1000ml four-neck flask equipped with electric mechanical stirring and a constant temperature heating oil bath, and stir until it is a homogeneous phase. Subsequently, 24.3 g (0.3 mol) of 37% formaldehyde aqueous solution B was slowly added dropwise. After completion of the dropwise addition, the reaction was carried out at 100° C. for 8 hours. After the reaction, it was cooled for later use.

[0069] (2) Esterification reaction

[0070] In a 2L round bottom flask, add (1) the polycondensate after the reaction, add 200g of polyether D (polyethylene glycol monomethyl ether 2000, 0.1mol), and 236g of cyclohexane with water agent, install a condenser, and raise the temperature To 100°C, react for 16 hours, cool down to about 60°C, add 200g of water, enter the separation device, separate the...

Embodiment 2

[0074] In this embodiment, B / (A+D)=1:1, A / D=2.0, E / D=1.0.

[0075] (1) Polycondensation reaction

[0076] In a 1000ml four-neck flask equipped with electric mechanical stirring and constant temperature heating oil bath, add 27.6g (0.2mol) of p-hydroxybenzoic acid A, 17.4g (0.1mol) of p-hydroxybenzenesulfonic acid, 10g (0.1mol) of sulfuric acid C ), and stir until it is a homogeneous phase. Subsequently, 24.3 g (0.3 mol) of 37% formaldehyde aqueous solution B was slowly added dropwise. After completion of the dropwise addition, the reaction was carried out at 130° C. for 2 hours. After the reaction, it was cooled for later use.

[0077] (2) Esterification reaction

[0078] In a 2L round bottom flask, add (1) the polycondensate after the reaction, add 200g of polyether D (polyethylene glycol monomethyl ether 2000, 0.1mol), and 236g of cyclohexane with water agent, install a condenser, and raise the temperature To 100°C, react for 16 hours, cool down to about 60°C, add 200g ...

Embodiment 3

[0082] In this embodiment, B / (A+D)=1:1, A / D=1.0, E / D=1.0.

[0083] (1) Polycondensation reaction

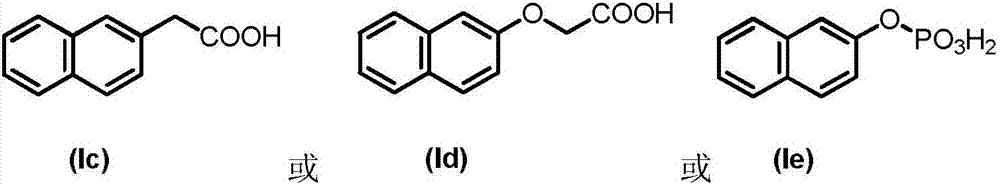

[0084] In a 1000ml four-necked flask equipped with electric mechanical stirring and constant temperature heating oil bath, add 43.6g (0.2mol) of phenoxyethanol phosphate A, 27.6g (0.2mol) of phenoxyethanol, 12.5g (0.125mol) of sulfuric acid C ), and stir until it is a homogeneous phase. Subsequently, 24.3 g (0.3 mol) of 37% formaldehyde aqueous solution B was slowly added dropwise. After completion of the dropwise addition, the reaction was carried out at 115° C. for 6 hours. After the reaction, it was cooled for later use.

[0085] (2) Esterification reaction

[0086]In a 2L round bottom flask, add the polycondensate after (1) reaction, add polyether D 600g (polyethylene glycol monomethyl ether 3000, 0.2mol), bring water agent toluene 600g, install a condenser, and heat up to 140 ℃, react for 12 hours, cool down to about 60 ℃, add 200g of water, enter the separation device,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com