Printing color quality measurement method

A quality testing and color technology, applied in printing, printing machines, general parts of printing machinery, etc., can solve the problem of lack of printing color quality testing methods, etc., to achieve the effect of easy operation

Active Publication Date: 2017-08-15

北京奇良海德印刷股份有限公司

View PDF11 Cites 21 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] The purpose of the present invention is to provide a printing color quality testing method to solve the problem that existing printing companies lack a simple and easy-to-operate printing color quality testing method

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0029] In this embodiment, the ImageControl image control system is used to assist in completing the printing test. Specifically include the following steps:

[0030] Step 1: Preparation before the test

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

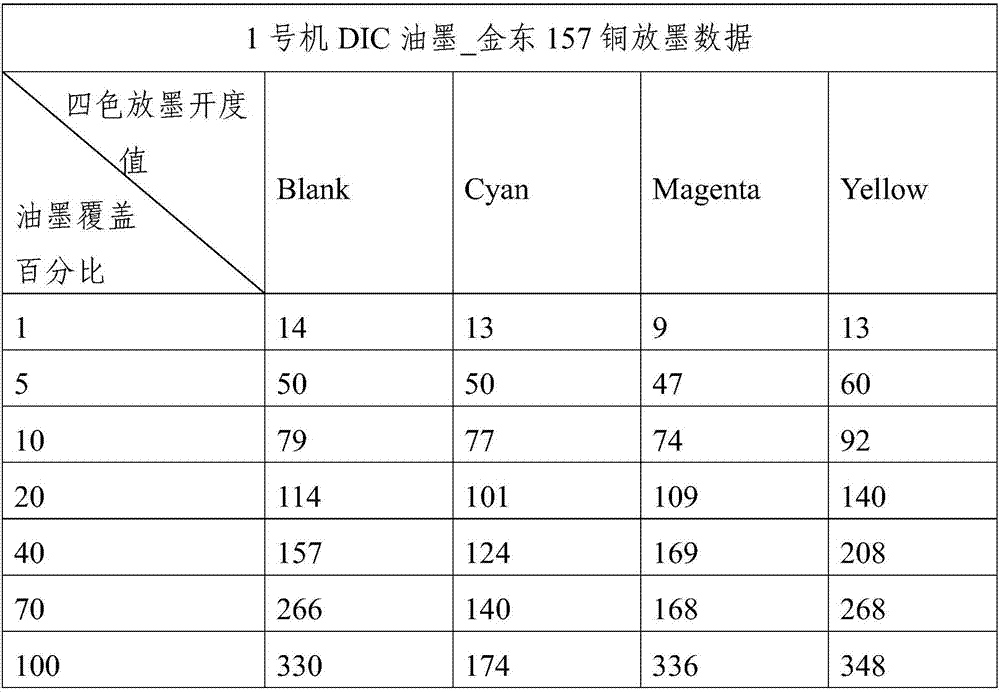

The invention discloses a printing color quality measurement method. The method comprises the steps of measurement pre-preparation, pre-printing normalization, standardization inspection of a printing machine, ink-water balance measurement, determination of optimal solid density, ink outputting curve measurement of the printing machine, printing of standard samples, manufacturing a printing machine curve, verification of the printing machine curve, analysis of the printing samples, and correction of network data. According to the printing color quality measurement method, printing data is effectively analyzed and corrected through the strict and normal measurement, and the method has quite high practical value and wide application prospects.

Description

technical field [0001] The invention relates to the technical field of printing, in particular to a method for testing printing color quality. Background technique [0002] The main problem that has been plaguing the practitioners in printing companies is the standardization of equipment and a set of effective color control methods. Most domestic companies are unable to find a simpler and easier-to-operate method in the process of color management of printing machines. The method is mainly manifested in the inability to monitor the state of the machine in real time, the inability to automatically control the ink zone adjustment of the printing press by means of data, and the inability to effectively analyze and correct the printing data. The present invention proposes a main printing color quality test method, through the real-time color adjustment and monitoring of the printing machine, the production of printing machine dot data and strict and standardized testing, the pri...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B41F33/00

CPCB41F33/0009B41F33/0036

Inventor 朱有根崔雁郁同刚肖荣

Owner 北京奇良海德印刷股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com