Equipment for automatically pressing decorative ring of automobile instrument

A technology for automotive instruments and decorative rings, applied in metal processing equipment, vehicle parts, transportation and packaging, etc., can solve the problems of low assembly pass rate, high assembly difficulty, low work efficiency, etc., achieve convenient operation, save assembly time, The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

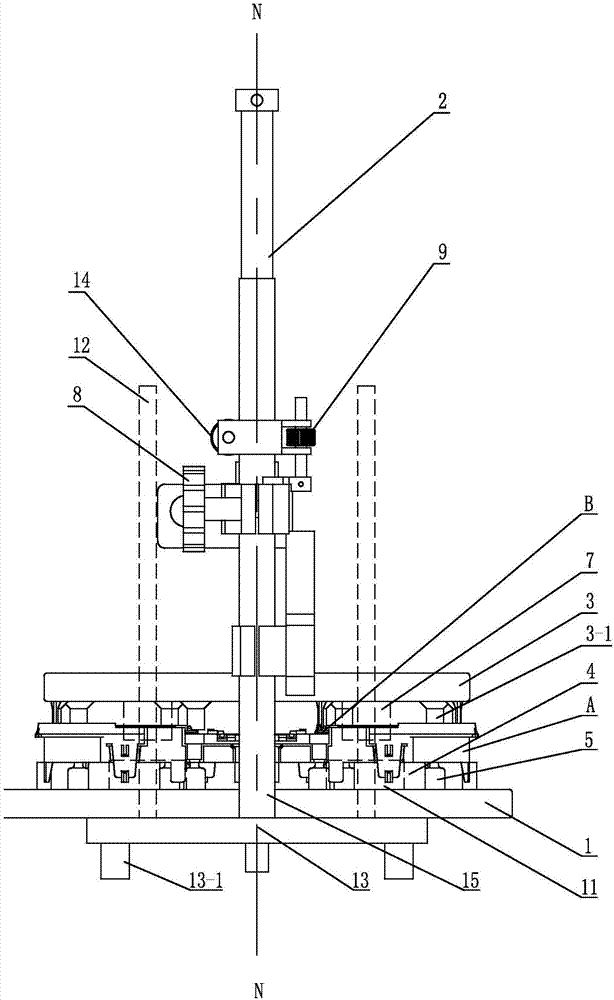

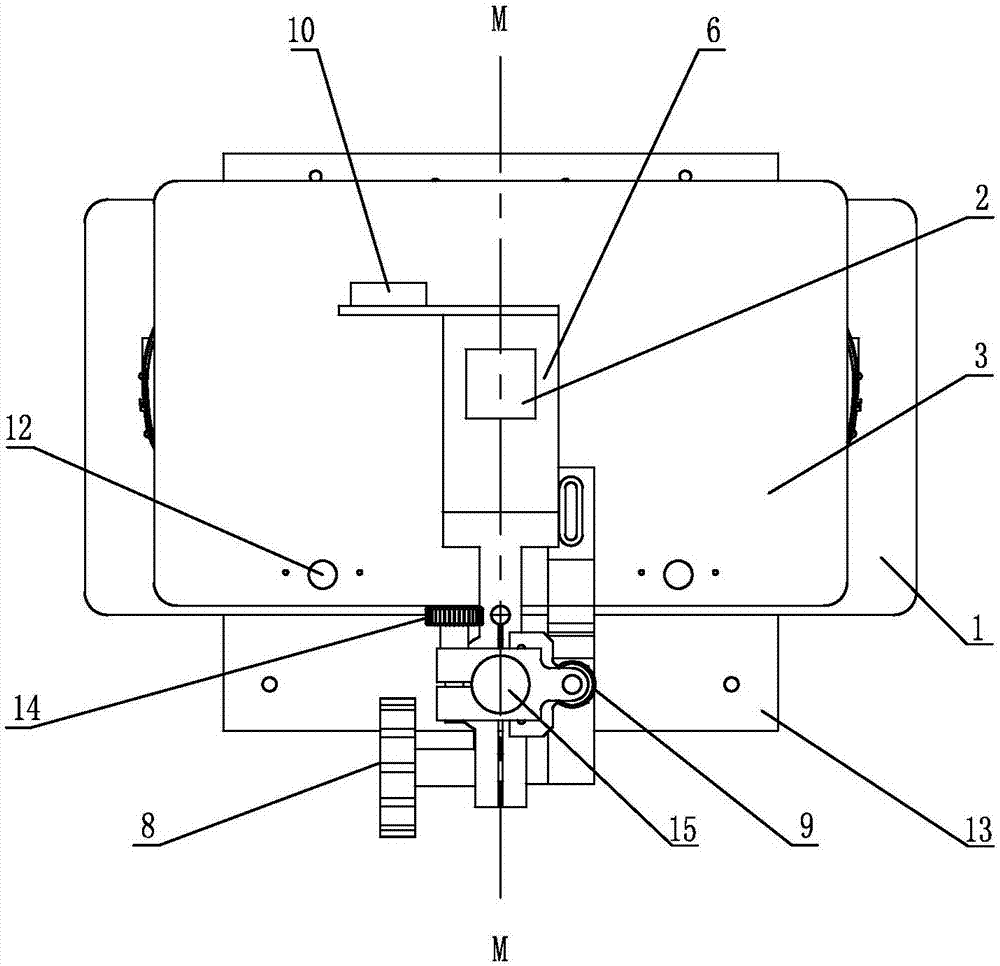

[0023] Specific implementation mode one: combine Figure 1 to Figure 4 Describe this embodiment, a device for automatically pressing a decorative ring for an automobile instrument in this embodiment, which includes a base plate 1, a cylinder 2, an upper pressing plate 3, a slide plate 6, a slide plate knob 8, a pneumatic knob 10, a seat plate 13, and a support column 15 , two support limit blocks 4, two linear bearings 7, two optical axes 12 and a plurality of pallets 5, the upper platen 3, the bottom plate 1 and the seat plate 13 are all rectangular plates, the upper platen 3, the base plate 1 and the seat plate 13 is arranged in sequence from top to bottom along the N-N direction of the longitudinal axis of the cylinder 2, the seat plate 13 is placed horizontally, the bottom plate 1 is fixed on the seat plate 13, the two support limit blocks 4 are cylindrical limit blocks, and the two cylindrical limit blocks The positioning blocks 4 are symmetrically arranged on the upper e...

specific Embodiment approach 2

[0024] Specific implementation mode two: combination figure 1 This embodiment will be described. The lower end of the seat plate 13 in this embodiment is provided with a plurality of bosses 13-1. Such setting ensures the stability of the seat plate 13, so that the seat plate 13 can be placed on the worktable smoothly. Other compositions and connections are the same as in the first embodiment.

specific Embodiment approach 3

[0025] Specific implementation mode three: combination figure 1 The present embodiment will be described. The heights of the plurality of trays 5 in this embodiment are equal to the heights of the two support stoppers 4 . Such an arrangement ensures the flatness of the workpiece A on the plurality of pallets 5 and the two supporting limit blocks 4 . Other compositions and connections are the same as those in Embodiment 1 or Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com