Laser assisting ultraprecise flying cutting monocrystalline germanium two-dimensional optical rotary drum method

A laser-assisted, ultra-precise technology, used in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of cutting edges and broken edges, and achieve the effect of reducing breaking strength, ensuring high quality, and avoiding the phenomenon of broken edges.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0015] In order to further illustrate the technical solution of the present invention, in conjunction with the accompanying drawings, the specific implementation of the present invention is as follows:

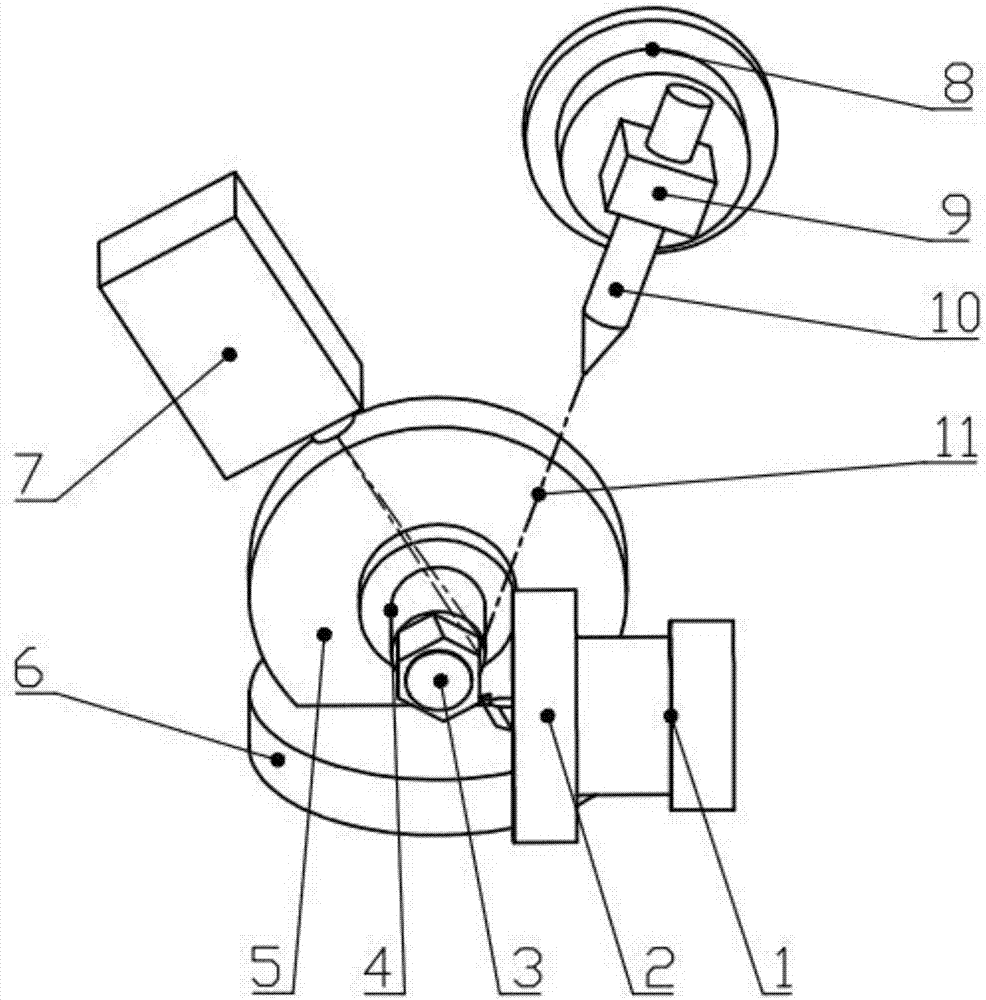

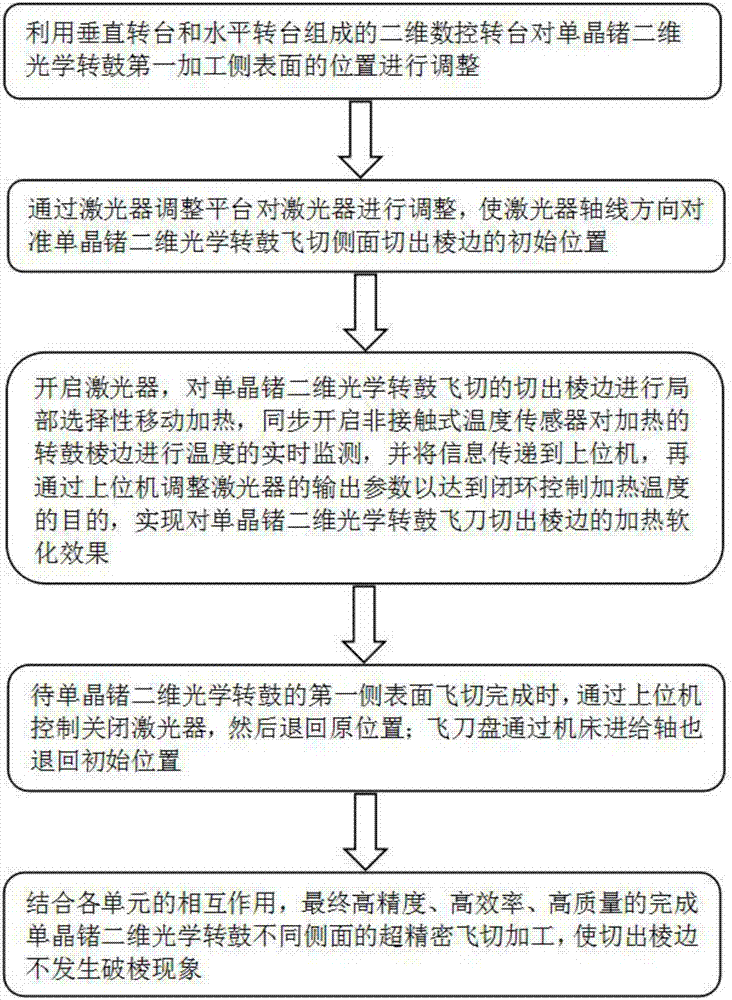

[0016] refer to figure 1 , the present invention provides a method for laser-assisted ultra-precision fly-cutting of a single-crystal germanium two-dimensional optical drum. In this embodiment, the laser-assisted ultra-precision fly-cutting method for a single-crystal germanium two-dimensional optical drum cutting unit, laser-assisted processing unit and temperature closed-loop control unit; the ultra-precision fly-cutting unit is installed on the fixed platform of the machine tool perpendicular to the 1-axis direction of the fly-cutting spindle, which is convenient for the processing and adjustment of the ultra-precision fly-cutting process, and the laser-assisted processing unit The installation position is located in the direction where the flying cutter head 2 fly-cuts the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com