rolling forming equipment

A technology of forming equipment and rotating shaft, applied in the field of steel rolling, can solve the problems of low production efficiency, high labor intensity, time-consuming and labor-intensive, etc., and achieve the effect of improving the performance of the equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

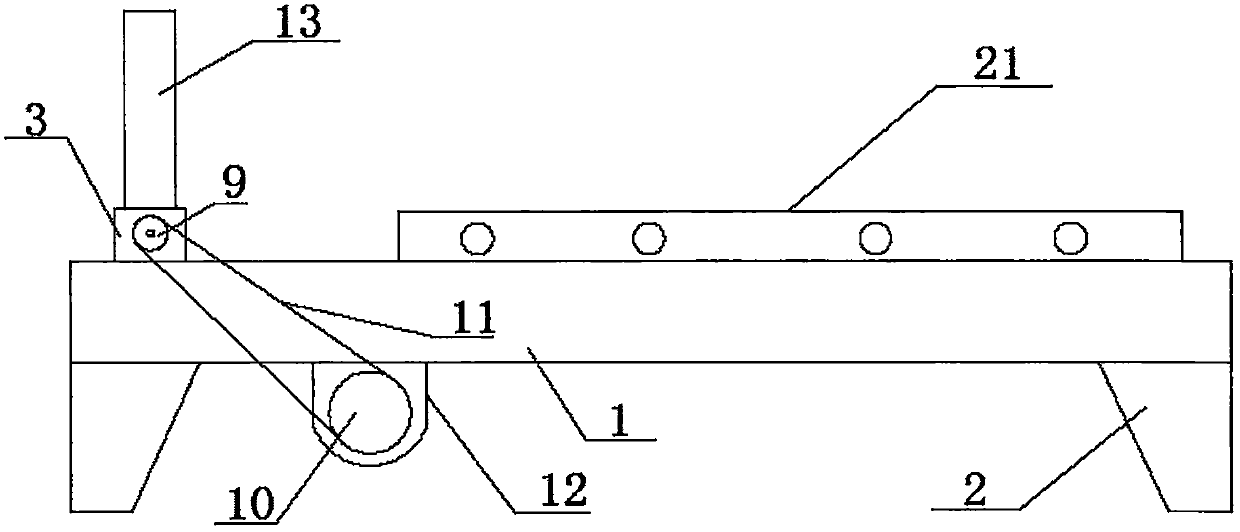

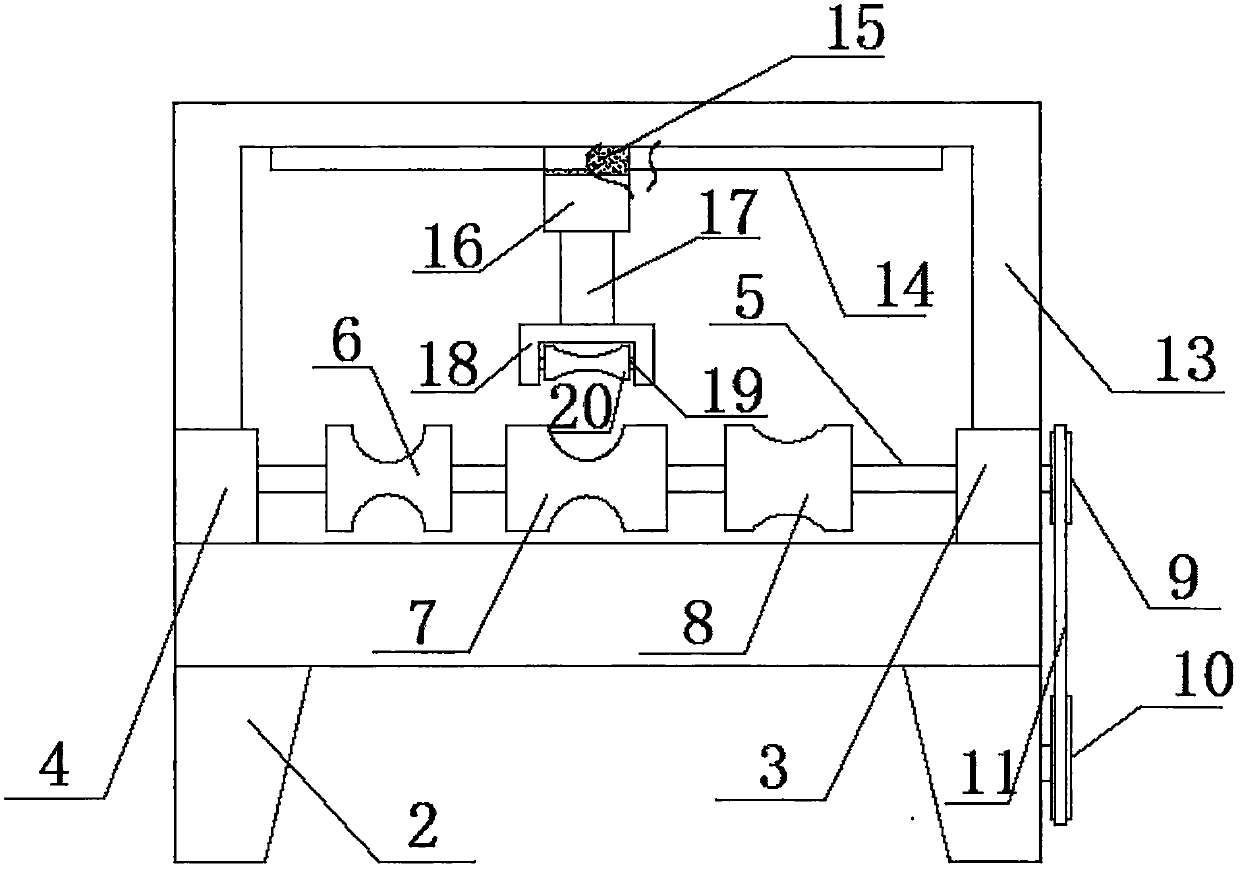

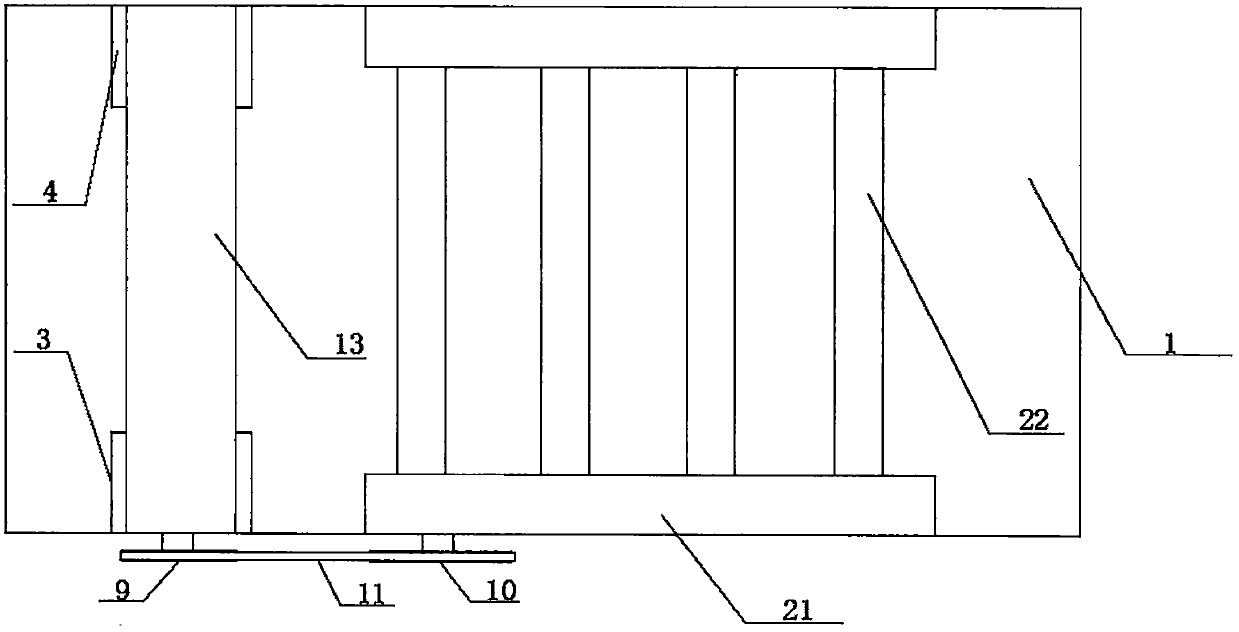

[0021] A steel rolling forming equipment, comprising a base 1, the top of the base 1 is provided with a first support 3 and a second support 4, and the first support 3 and the second support 4 are rotatably connected with a second support through a bearing. A rotating shaft 5, one end of the first rotating shaft 5 is provided with a small belt pulley 9, the bottom of the base 1 is provided with a motor 12, and the output end of the motor 12 is provided with a large belt pulley 10, and the large belt pulley 10 passes through the belt 11 The belt drive is connected to the small belt pulley 9, the first rotating shaft 5 is also provided with a first rolling module 6, a second rolling module 7 and a third rolling module 8, the first support 3 and the second support The top of the seat 4 is provided with a support 13, and the bottom of the support 13 is provided with a chute 14, and a slide block 15 is slidably connected in the chute 14, and a hydraulic cylinder 16 is provided at th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com