Rolling machine

A technology of a plate rolling machine and a frame is applied in the field of forging equipment, which can solve the problems of limited space adjustment range, inability to effectively roll thick plates, and difficulty in further adjusting the centerline distance of side rollers, etc., to achieve the effect of improving the rolling capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to make the technical means, creative features, goals and effects of the present invention easy to understand, the following embodiments will specifically illustrate the plate rolling machine of the present invention in conjunction with the accompanying drawings.

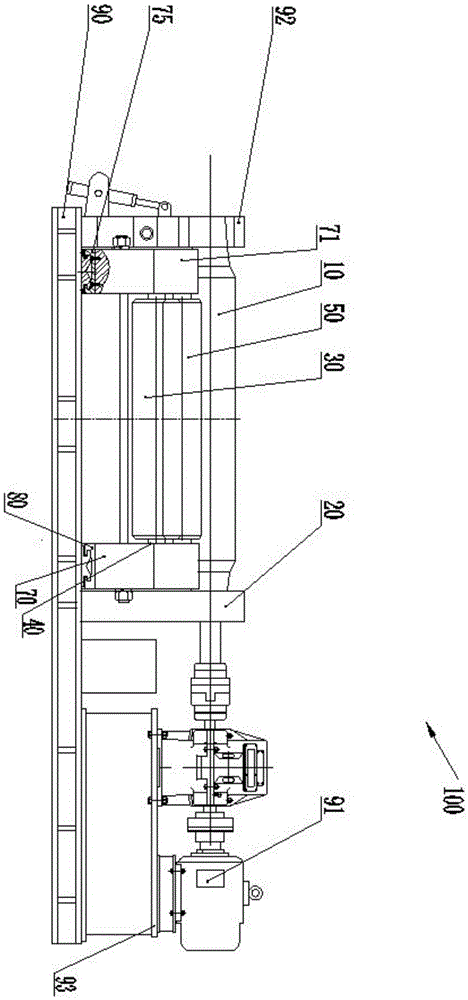

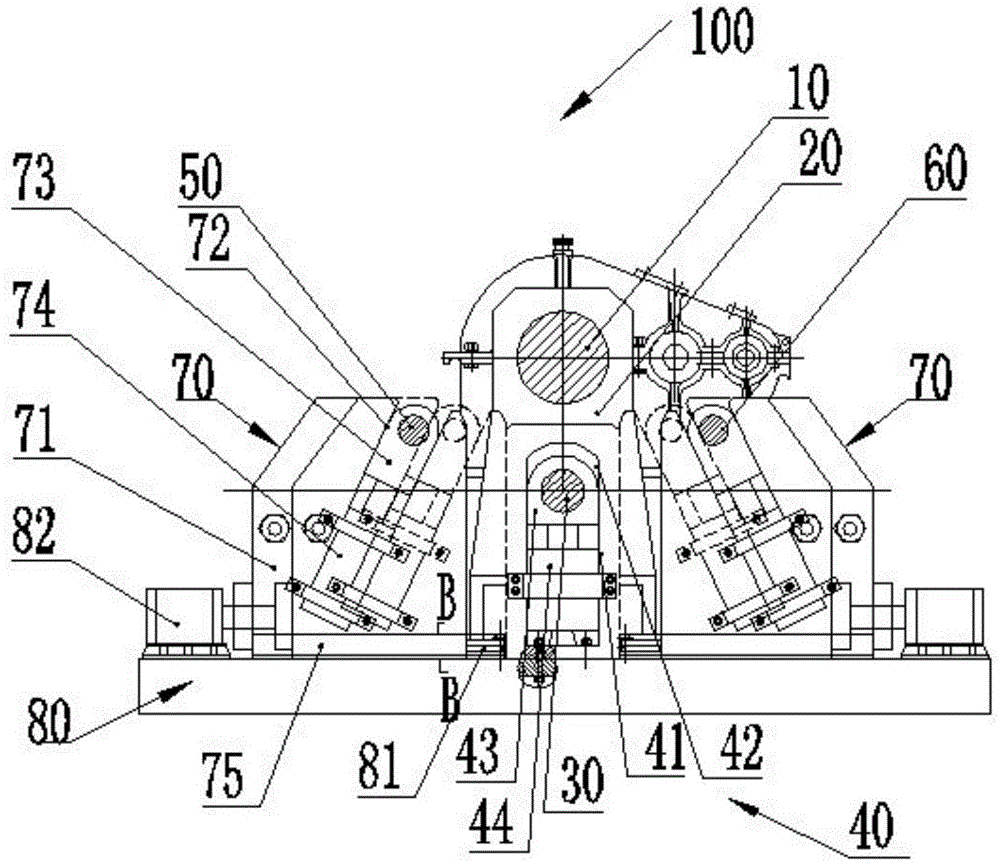

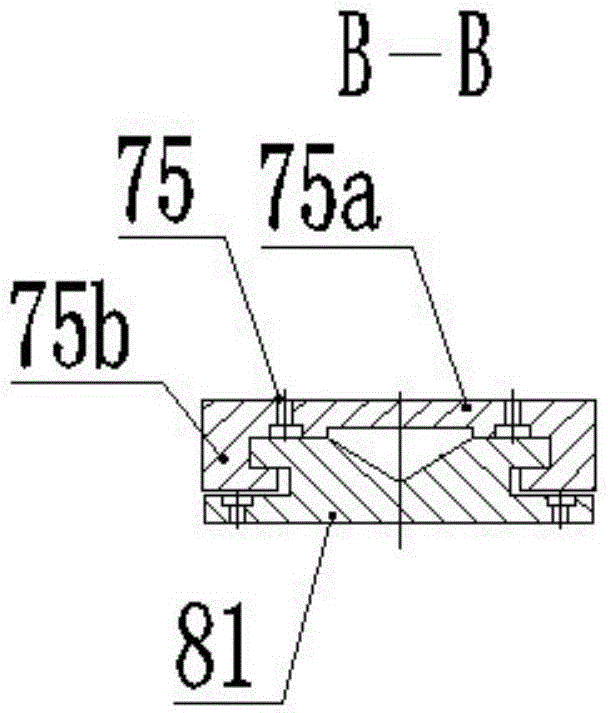

[0015] figure 1 It is a structural schematic diagram of the bending machine in the embodiment of the present invention.

[0016] Such as figure 1 As shown, in this embodiment, the plate rolling machine 100 can roll plates with different thicknesses, and the plate rolling machine 100 in this embodiment is a four-roller plate rolling machine.

[0017] The plate rolling machine 100 includes: an upper roll 10, two upper roll fixing parts 20, a lower roll 30, a lower roll fixing part 40, a left side roll 50, a right side roll (not shown in the figure), two side roll fixing parts 70 , two horizontal adjustment parts 80, a machine base 90, a power assembly 91, an overturning assembly 92 and a controller 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com