Blowback ash removal device and blowback ash removal system

A ash cleaning device and ash cleaning technology, used in transportation and packaging, dispersed particle filtration, membrane filters, etc., can solve the problems of poor ash cleaning effect, affecting filter life and filtration efficiency, etc., and achieve comprehensive and improved ash cleaning. Good cleaning effect and turbulent flow effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

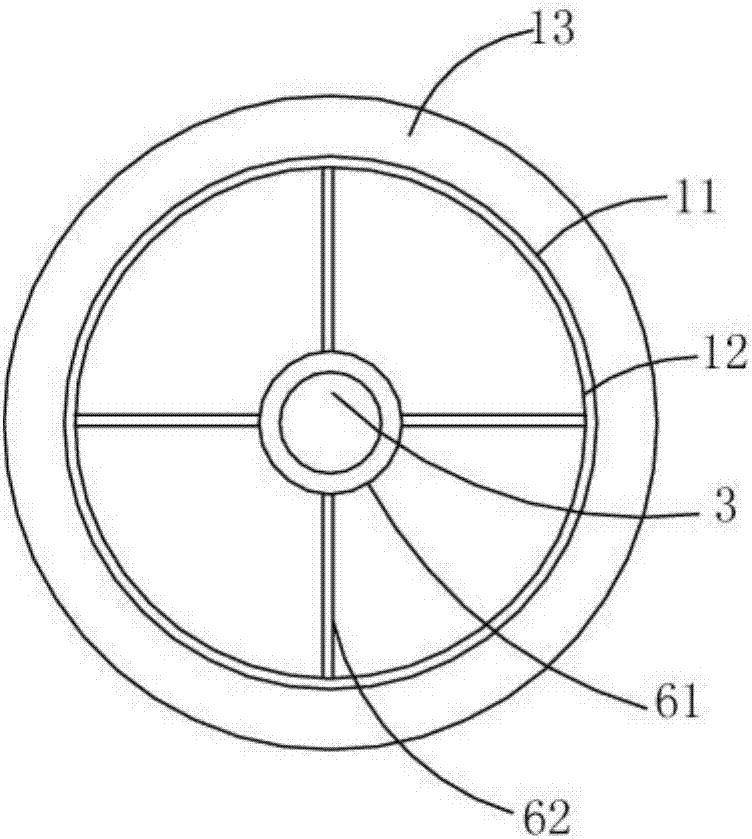

[0037] like figure 1 The back blowing soot cleaning system shown is used for the cleaning treatment of the tubular filter assembly. The tubular filter assembly includes an orifice plate 2 and six tubular filters 1. The tube Type filter 1 is firmly connected with the orifice plate 2 through the ring 13 protruding from the upper end; The six blowing pipes 41 and the six back-blowing and dust-cleaning devices corresponding to the six tubular filters 1 one-to-one.

[0038] like Figure 2-4 As shown, each back blowing soot cleaning device is used for back blowing soot cleaning of the corresponding tubular filter 1, and the tubular filter 1 includes an external filter membrane 11, an internal filter for supporting the filter membrane 11 A support frame 12 and an air outlet channel formed in the support frame 12; the back blowing dust removal device includes a back blow pipe 3 that matches the length of the tubular filter 1 in the air outlet channel, and the back blow The blowpipe...

Embodiment 2

[0049] like Figure 5 As shown, on the basis of Embodiment 1, the size of the inner end of the air outlet hole 320 in this embodiment is smaller than the size of the outer end. Under the same cleaning thickness, the back blowing pressure required in this embodiment is smaller and the cleaning is more comprehensive, especially for local locations such as corners, which can also be effectively cleaned.

Embodiment 3

[0051] like Image 6 As shown, on the basis of Embodiment 1, the air outlet holes 320 of two adjacent air outlet units 32 of this embodiment are arranged at intervals. Under the same backflushing pressure, the dust removal in this embodiment is more comprehensive.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com